Introduction to 500 BPH Chicken Slaughter Lines

The 500 bph chicken slaughter line is a specialized assembly designed for the processing of poultry at a rate of 500 birds per hour. This category encompasses a comprehensive system for slaughtering, defeathering, eviscerating, and chilling, tailored to meet the demands of medium-scale poultry processors.

Components and Functionality

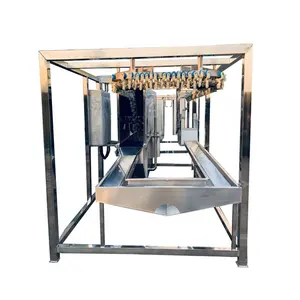

A typical chicken processing line includes various modules such as stunning, killing, scalding, defeathering, eviscerating, and chilling units. Each component is engineered to work seamlessly, ensuring a humane and efficient process. The line is constructed to maintain the integrity of the meat and comply with food safety standards.

Material and Durability

Constructed from robust materials, the poultry processing equipment is designed to resist corrosion and ensure longevity. Stainless steel is predominantly used for its ease of cleaning and resistance to the harsh conditions of a processing environment.

Operational Efficiency

Efficiency is paramount in a chicken slaughterhouse line. The design focuses on reducing bottlenecks and ensuring a continuous flow of operations, which is crucial for businesses aiming to optimize their output while maintaining quality.

Hygiene and Maintenance

Hygiene is a critical aspect of any meat processing line. The equipment is designed for easy cleaning and maintenance, with components accessible for sanitation procedures. This not only helps in maintaining product quality but also in adhering to health and safety regulations.

Considerations for Procurement

When selecting a 500 bph chicken slaughter line, considerations should include the machine's capacity to handle the desired throughput, the availability of spare parts, and the ease of integration into existing operations. It is essential to evaluate the adaptability of the equipment to various poultry sizes and the versatility of the processing components.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4