Introduction to Multi-Spindle Drilling Machines

Multi-spindle drilling machines, particularly the 6 spindle drilling machine, stand as a cornerstone in modern manufacturing, offering versatility and efficiency in drilling operations. These machines are engineered to create precise cylindrical or tapered holes in various materials, primarily wood. With a focus on the 6 spindle drilling machine, this category encompasses equipment designed for both high-volume production and intricate customization.

Types and Applications

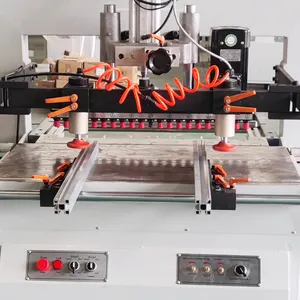

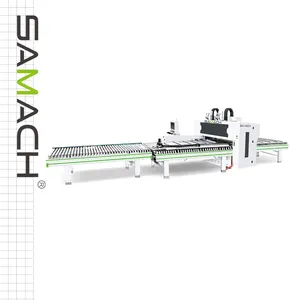

The 6 spindle drilling machine category includes diverse types tailored to specific applications. Horizontal boring machines, for instance, utilize a spindle aligned parallel to the worktable, ideal for lengthy or heavy workpieces. In contrast, vertical boring machines demand the workpiece to be clamped before the overhead spindle performs the boring operation. Line boring machines, supporting a bar at both ends, are adept at boring holes in large structures. These machines serve industries ranging from furniture manufacturing to construction, where precision drilling is paramount.

Features and Materials

Each 6 spindle drilling machine is equipped with features that enhance performance and user experience. The spindles, crafted from robust materials, ensure durability and consistent operation. The machines' design allows for drilling holes of various shapes and depths, catering to complex project requirements. The construction of these machines often involves heavy-duty steel and cast iron, providing stability and longevity.

Advantages of Using a 6 Spindle Drilling Machine

The practicality of a 6 spindle drilling machine lies in its ability to expedite work processes. Compared to manual drilling, these machines significantly reduce the time required to complete tasks, thereby increasing productivity. Moreover, they operate with precision and minimal noise, making them suitable for various environments without the concern of noise pollution or odors often associated with other milling equipment.

Choosing the Right 6 Spindle Drilling Machine

Selecting the appropriate 6 spindle drilling machine involves understanding the specific requirements of your project. The machine's adaptability to drill holes of varying dimensions and configurations allows for a broad range of applications. When considering a purchase, it is essential to evaluate the machine's compatibility with the intended drilling tasks to ensure efficient and effective operation.

Conclusion

The 6 spindle drilling machine is a valuable asset in any production line that requires drilling operations. Its ability to perform with precision and efficiency makes it a sought-after piece of equipment for businesses looking to optimize their manufacturing processes. While Alibaba.com serves as a platform to connect buyers with a variety of suppliers offering these machines, it is crucial to assess the specifications and features of each machine to find the one that best suits your operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4