Exploring the Versatility of Aluminum Extrusion Tension Locks

Aluminum extrusion tension locks are integral components in various industries, known for their robustness and adaptability. These locks serve as pivotal connectors in systems ranging from construction frameworks to intricate office furniture assemblies. The versatility of aluminum extrusion tension locks stems from their ability to offer secure fastening in diverse applications, ensuring stability and precision in every project.

Types and Shapes of Aluminum Extrusion Tension Locks

The array of shapes and forms of tension locks is extensive. Manufacturers offer a multitude of profiles, such as L-angled brackets, square and round tubes, both solid and hollow, and T-shaped bars. Additional configurations include J caps, Z clips, and various channels, each serving a unique purpose in assembly and installation processes. These profiles are predominantly crafted from durable 6000 series aluminum alloy, with customizable temper options from T3 to T8 to meet specific project requirements.

Applications and Features

Aluminum extrusion tension locks are not limited to a single industry. Their applications span across sectors, including but not limited to, innovative interior designs, efficient lighting systems, automotive components, and dynamic plumbing solutions. The features of these locks, such as their diverse shapes and the ability to withstand substantial tension, make them suitable for complex engineering challenges.

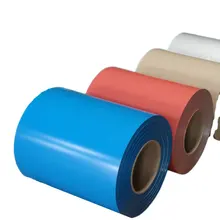

Material Specifications and Surface Treatments

The material thickness of these locks can range from 0.2mm to 20mm, catering to various levels of structural demands. Surface treatments are comprehensive, offering finishes like powder coating, anodizing, and sandblasting. Each treatment ensures that the aluminum profiles meet both aesthetic and functional standards. Anodizing, for instance, not only adds a splash of color but also enhances corrosion resistance, while wood grain finishes mimic the natural appearance of wood, ideal for decorative purposes.

Advantages of Using Aluminum Extrusion Tension Locks

The advantages of using aluminum tension locks are manifold. Their lightweight nature coupled with exceptional strength makes them a preferred choice in scenarios where weight management is crucial without compromising on structural integrity. The adaptability in terms of surface finishing allows for a range of appearances, from sleek, polished exteriors to rugged, matte textures, providing solutions that are as aesthetic as they are functional.

Selecting the Right Aluminum Extrusion Tension Lock

Choosing the right aluminum extrusion tension lock is pivotal for the success of any project. Factors to consider include the specific application, the required strength, and the desired aesthetic outcome. With a comprehensive selection available, finding the appropriate profile is a streamlined process. Professionals in various fields can rely on the versatility and quality of these components to fulfill their project needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4