In the domain of vehicle upkeep and repair, automotive engineering tools are the bedrock of precision, efficiency, and safety. Far from mere instruments, these tools are the vital essence of car workshops, encapsulating the technological strides and acumen necessary to navigate the intricacies of contemporary vehicles.

Types and Functions of Automotive Engineering Tools

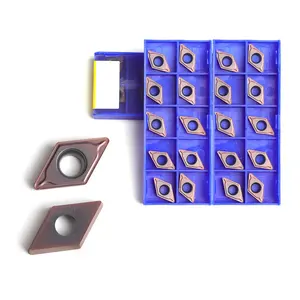

A broad array of automotive engineering tools exists, each with unique features. For example, the car oil filter wrench is available in chain-loop, socket-style, and strap-type variants, each suited to different oil filter sizes and designs. Automotive valve grinding machines vary from basic manual devices to sophisticated, heavy-duty apparatuses. The on car valve spring compressor also comes in models tailored for overhead camshaft engines or for valves that are deeply set. Each tool is crafted for specific functions, such as tightening or loosening, providing leverage, or facilitating precision, all of which are vital in the detailed realm of car repair.

Structure and Materials of Automotive Tools

The architecture of these tools is an engineering wonder, with every element playing a crucial role. Consider the automotive compression test kit, which typically comprises a gauge, hose, and assorted fittings. The gauge must be both sturdy and legible for precise measurements, while the hose should be both pliable and resilient to endure high pressures. The automotive cylinder hone is equipped with stones to smooth cylinder walls and a mechanism that guarantees uniform pressure for a polished finish. These components are designed to operate in concert, ensuring the tool's efficiency and effectiveness.

Materials and Benefits

Hardened steel, known for its strength and endurance, is often employed in tools like the car oil filter tool. Carbon steel is preferred for its robustness, making it suitable for automotive timing tools that demand precision. Parts of the automotive valve spring compressor tool frequently utilize stainless steel for its anti-corrosive properties. These materials are selected not just for their durability but also for their capacity to endure the demands of automotive tasks, assuring reliability and safety.

Business Usages and Applications

In the automotive sector, these tools are essential. The automotive valve grinder, for instance, is vital in engine rebuilding workshops for resurfacing valve areas. Diagnostic tools like the car compression test kit are employed in service stations to swiftly gauge engine condition. In educational environments, these tools are instrumental in training aspiring mechanics, offering practical experience with the gear they will utilize professionally. Each tool adds business value by enhancing service standards, minimizing downtime, and boosting the overall productivity of vehicle maintenance operations.

Features and Advantages of Automotive Engineering Tools

The attributes of automotive engineering tools are conceived with the end-user in mind. For example, the ergonomic design of a car oil filter wrench facilitates a firmer grip and greater torque with minimal exertion. The precision of an automotive valve grinding machine guarantees an impeccable seal between valve and seat, augmenting engine efficiency. These features are not mere conveniences; they epitomize the deliberate fusion of design and utility that distinguishes these tools from their rivals.

Benefits and Positive Outcomes

The advantages of employing specialized automotive engineering tools are numerous. They not only address the immediate issue, such as dislodging a recalcitrant oil filter with a car oil filter tool, but also fulfill broader objectives by enhancing the efficiency and safety of automotive tasks. Utilizing an automotive compression test kit can lead to early identification of engine problems, averting expensive repairs in the future and prolonging the vehicle's lifespan.

How to Use and Maintain Automotive Engineering Tools

Proficient use of these tools necessitates expertise and finesse. When employing an on car valve spring compressor, it's imperative to apply pressure uniformly to avoid harming the valve mechanism. Selecting the correct model, such as opting for a Pittsburgh automotive compression test kit with the right range for your engine, is essential. Maintenance and cleaning are straightforward yet vital; routine lubrication and storage in a dry, clean space can significantly prolong the tools' service life. Installation of certain tools, like a car oil filter wrench, is typically tool-free but may necessitate familiarity with the vehicle's configuration for proper application.

Target Audience and Meeting Needs

The intended users for these tools are varied, spanning from professional mechanics to car aficionados. Repair shop professionals benefit from the resilience and exactitude of tools like the automotive valve grinding tools, whereas hobbyists value the simplicity and efficacy of a car oil filter tool for home maintenance. These tools are crafted with the user's requirements in mind, whether it's ease of use for the novice or the sturdiness needed by the professional.

How does the automotive engineering tool enhance the efficiency of vehicle maintenance?

Specialized automotive engineering tools markedly elevate the efficiency of vehicle maintenance. These tools are tailored to fit specific vehicle parts and components, diminishing the time and labor needed for disassembly and reassembly. For instance, the automotive valve spring compressor tool streamlines the replacement of valve springs, a procedure that would otherwise be arduous and protracted.

What are the considerations when selecting automotive engineering tools for a workshop?

Choosing the appropriate tools for a workshop entails evaluating the types of vehicles serviced, the regularity of certain repairs, and the technicians' skill level. A comprehensive set, including a car compression test kit and automotive valve grinding tools, caters to a wide array of diagnostic and repair tasks. The quality and warranty of the tools should also be taken into account, as they represent a substantial investment for any enterprise.

How do advancements in automotive tools impact the industry?

Progress in automotive engineering tools profoundly influences the industry by facilitating more intricate repairs and diagnostics with enhanced precision and reduced time. Innovations such as the on car valve spring compressor and the automotive compression test kit permit in-situ repairs that were once unfeasible or necessitated extensive dismantling. This leap in tool design and functionality directly correlates to heightened productivity and profitability for automotive enterprises.

Delving into the extensive selection of automobile engineering tools on Alibaba.com unveils a dedication to excellence and innovation, serving the varied demands of the automotive repair industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4