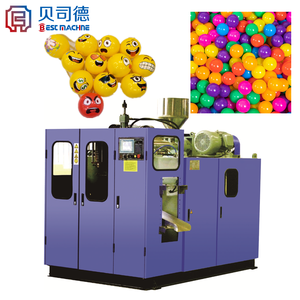

Introduction to Ball Blow Molding Machines

Ball blow molding machines are specialized equipment used in the manufacturing industry to produce hollow plastic parts. This machinery is essential for creating a wide range of products, from small containers to large barrels. The versatility of these machines allows for the production of items with varying complexities and specifications.

Understanding the Molding Processes

The blow molding process is categorized into three primary methods: Injection Blow Molding, Extrusion Blow Molding, and Injection Stretch Blow Molding. Each technique utilizes a unique approach to shape plastic materials into desired forms. Injection Blow Molding employs a core rod throughout the process, ensuring precision and consistency. Extrusion Blow Molding is known for its adaptability in creating various shapes and sizes, while Injection Stretch Blow Molding is ideal for producing high-clarity and high-strength containers.

Materials and Features

Ball blow molding equipment is designed to handle a range of materials, including eco-friendly options such as recycled plastics. The machines come equipped with features like full proportional control systems, which allow for precise adjustments during production. Advanced models may include angled blow pins and sophisticated controllers to enhance the manufacturing process. Additionally, many machines are integrated with auxiliary components like conveyors to streamline the production line.

Applications and Advantages

The application of blow molding machines spans across various industries, from packaging to automotive components. The advantages of using these machines include their ability to produce lightweight, durable products with excellent material distribution. This process is also cost-effective for high-volume production runs, making it a popular choice for businesses looking to scale their operations.

Selecting the Right Machine

Choosing the appropriate blow molding machine depends on the specific requirements of the production task. Factors such as material type, product size, and desired output rate play a crucial role in determining the most suitable machine. Suppliers on Alibaba.com offer a diverse range of machines, each with different specifications to cater to various production needs.

Connect with Trusted Suppliers

For businesses seeking to enhance their production capabilities, connecting with reliable suppliers of ball blow molding machines is essential. Alibaba.com serves as a platform where you can find a comprehensive list of machines, compare different models, and communicate with suppliers to obtain further details and specifications tailored to your operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4