Introduction to BOPP Making Machines

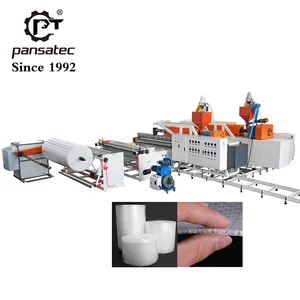

Biaxially Oriented Polypropylene (BOPP) making machines are integral components in the production of BOPP films, commonly used for packaging tapes, labels, and various types of wraps. These machines are designed to produce BOPP films through a process of melting, extruding, and stretching polypropylene to its biaxial orientation, enhancing its strength and clarity.

Types and Applications

The versatility of BOPP making machines allows for the production of a range of products. BOPP tape making machines and bopp bag making machines are popular variants, catering to the packaging industry. Specialized machines like bopp pouch making machines and bopp side sealing machines are tailored for specific product formats, while fully automatic self adhesive bopp tape making machines streamline the production process for adhesive tapes.

Technical Specifications and Features

BOPP making machines are equipped with advanced features to ensure efficiency and quality. These include air compressor pneumatic systems and PLC control panels for automated operations. The production capacities can reach approximately 150 meters per minute, with some machines capable of producing around 3 tons of BOPP film per day. The machinery's weight and configurations may vary, with larger systems reaching upwards of 3,000 kilograms.

Materials and Advantages

Constructed to handle the rigors of industrial environments, BOPP making machines are typically made from robust materials that withstand continuous use. The production of BOPP films offers advantages such as improved durability, moisture resistance, and clarity, making it a preferred material for a multitude of packaging solutions.

Operational Efficiency

Operational efficiency is a hallmark of modern bopp manufacturing machines. The integration of technology allows for minimal manual intervention, reducing the likelihood of errors and increasing the consistency of the output. For businesses involved in recycling, machines like bopp roll making machines can turn waste into reusable materials, contributing to sustainable manufacturing practices.

Choosing the Right Machine

Selecting the appropriate BOPP making machine requires consideration of the specific needs of a production line. Factors such as the desired output, the type of BOPP product, and the available space for machinery installation are crucial. Alibaba.com hosts a wide array of machines, including shreeji tech engineering bopp tape making machines, to cater to diverse industry requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4