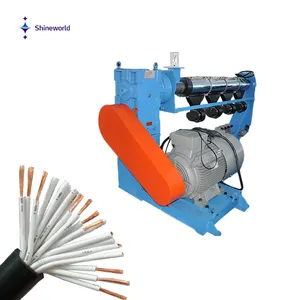

Introduction to Cable Granule Making Machines

Cable granule making machines are essential equipment in the recycling industry, designed to process electrical cables into small granules for reuse. These machines are adept at handling a variety of materials, including metals like copper and aluminum, as well as non-metallic substances such as plastic and rubber. The versatility of these machines makes them a valuable asset for businesses looking to manage waste effectively.

Types and Sizes

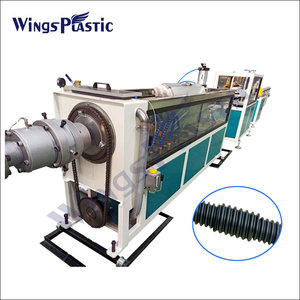

The range of cable granule making machines is extensive, with models to suit different scales of operation. Small-scale machines are compact, fitting into limited spaces and are ideal for smaller recycling operations. On the other end of the spectrum, large-scale machines cater to industrial recycling needs, capable of processing high volumes of material with their larger feeding ports and robust construction.

Machine Specifications and Features

When selecting a cable granule making machine, it's important to consider the specifications. These machines vary in weight, power consumption, and rotational speed, with some models featuring advanced components like conveyor belts and automatic lubrication systems. The construction of the cutting blades is another critical aspect, with materials ranging from stainless steel to carbon steel, ensuring durability and efficiency.

Customization and Applications

For businesses with specific needs, customization options are available to tailor a cable granule making machine to the required processing volume and material type. These machines are not just limited to cable recycling but can also handle other recyclable materials, making them a versatile choice for a wide range of applications.

Operational Efficiency

Operational efficiency is a key consideration, with medium and large machines offering features that enhance productivity. The number of cutting blades and the presence of single or double shafts can influence the machine's performance, with some capable of processing up to 20 tonnes per hour.

Environmental Impact and Sustainability

Investing in a cable granule making machine not only contributes to a business's operational efficiency but also promotes environmental sustainability. By converting waste into reusable materials, these machines play a crucial role in reducing the ecological footprint of cable waste.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4