Introduction to Caps Induction Seal

The caps induction seal is a critical component in packaging, ensuring product integrity by creating a hermetic seal. This technology is pivotal for preserving the quality of contents in a variety of containers, making it a staple in industries ranging from pharmaceuticals to food and beverage. The sealing process involves an electromagnetic field that heats a metallic disk to bond the seal to the container's mouth, providing tamper evidence and product freshness.

Types and Applications

There are several types of induction seal caps, each suited to different packaging needs. The heat induction sealer is commonly used for its efficiency and reliability. Applications are vast, including sealing bottles for liquids, jars for creams, and containers for health supplements. The adaptability of cap sealers allows them to be used on glass, plastic, and metal containers, demonstrating their versatility in sealing a wide range of products securely.

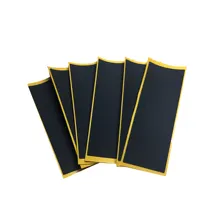

Features and Materials

The materials used in induction seals for PET bottles and other containers include aluminum foil, which is known for its excellent sealing properties. The seals often feature layers such as a polymer film that adheres to the container and a paper or foam layer for additional security. Features of these seals include resistance to moisture and air, contributing to the extended shelf life of the contents. The induction sealing process itself is designed to be efficient and can be performed with automatic induction sealers or handheld induction sealer devices, depending on the scale of operations.

Advantages of Induction Sealing

The use of induction foil sealer technology offers numerous advantages. It enhances product safety by providing a tamper-evident seal, which is crucial for consumer trust. Additionally, the seal's integrity is maintained without direct contact, ensuring the purity of the product. The process is also energy-efficient, with equipment like the enercon induction sealer designed to minimize power consumption while maximizing output.

Innovations in Induction Sealing

Innovation in the field has led to advanced solutions like the enercon super seal and enercon super seal jr, which cater to a range of container sizes and production capacities. The development of capless induction sealing has also emerged, allowing for the sealing of containers without traditional caps, which can be beneficial in certain packaging designs and for sustainability efforts.

Choosing the Right Induction Sealer

Selecting the appropriate sealer, whether it's an induction sealer for bottles or an induction sealer for caps, depends on various factors including container material, seal material, and production requirements. For specialized containers, such as an induction sealer for glass jars or induction sealer for plastic jars, it's important to ensure compatibility to achieve an optimal seal. The sealing process, whether for an individual artisan or a large-scale manufacturer, can benefit from the efficiency and security that induction sealing technology provides.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4