Cotton Waste Machine: An Overview

The cotton waste machine is a pivotal component in the textile industry, designed to address the need for efficient waste management. These machines are integral in processing excess cotton by-products, transforming them into usable forms for further manufacturing or recycling. The range of cotton waste machines includes various models tailored for different stages of textile production, from cleaning and recycling to shredding and baling.

Types and Applications

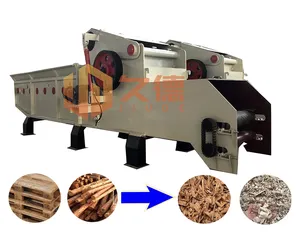

There are several types of cotton waste processing equipment, each serving a unique function within the industry. Common variants include cotton waste recyclers, openers, and fiber opening machines. These are utilized in settings such as manufacturing plants and garment shops, demonstrating versatility in application. The machinery is adept at handling tasks from simple waste collection to complex fiber repurposing, ensuring that every scrap of cotton can be redirected into a productive lifecycle.

Features and Functionality

The functionality of a cotton waste recycling machine is a testament to its design and technological advancement. These machines boast features that facilitate the efficient processing of cotton waste, such as high-capacity processing, energy efficiency, and user-friendly interfaces. The adaptability of the machines allows them to be integrated into various production lines, ensuring that they meet the diverse needs of the textile industry.

Materials and Construction

Durability is a cornerstone of cotton waste management equipment. Constructed from robust materials, these machines are built to withstand the rigors of continuous operation. The choice of materials also reflects a commitment to sustainability, with many machines featuring components that are recyclable or have a reduced environmental impact.

Advantages of Modern Cotton Waste Machines

Modern cotton waste disposal equipment offers a plethora of advantages. Their enhanced efficiency not only optimizes waste processing but also contributes to a reduction in the carbon footprint of textile operations. Furthermore, the automation capabilities of these machines reduce the need for manual labor, streamlining the waste management process and allowing for more consistent output.

Choosing the Right Cotton Waste Machine

Selecting the appropriate cotton waste treatment solution requires careful consideration of the specific needs of a facility. Factors such as machine capacity, compatibility with existing systems, and the type of waste being processed are crucial in making an informed decision. While Alibaba.com does not endorse any particular brand or model, the platform offers a comprehensive listing of suppliers, each providing detailed information to help buyers make the best choice for their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4