Introduction to Cushioning Pad Making Machines

Cushioning pads are essential components in packaging, providing protection and stability for goods during transport. The cushioning pad making machine is at the heart of producing these vital materials. These machines are engineered to meet diverse industrial requirements, ensuring that products reach their destinations unharmed.

Types and Applications

The variety of cushioning pad making machines caters to different industry needs. From small-scale operations to large manufacturing lines, these machines are designed to produce cushioning pads suitable for packaging electronics, glassware, and other fragile items. Their applications span across various sectors, including electronics, automotive, and consumer goods, highlighting their versatility in production capabilities.

Machine Features and Materials

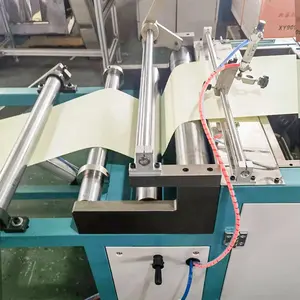

Modern cushioning pad making machines are equipped with advanced features that enhance efficiency and productivity. They typically handle a range of materials, such as kraft paper, corrugated fibers, and recycled paper, transforming them into durable cushioning pads. The machines come with adjustable settings to control pad thickness and density, ensuring the output matches specific packing requirements.

Advantages of Using Automated Machines

Utilizing automated cushioning pad making equipment offers numerous advantages. These machines streamline the production process, reduce labor costs, and increase the speed of production. Moreover, they are designed to minimize waste, promoting more sustainable manufacturing practices. The precision and consistency of automated machines also mean that each cushioning pad is of uniform quality, providing reliable protection for packaged goods.

Environmental Considerations

Sustainability is a growing concern in the packaging industry. Many cushioning pad production machines now boast eco-friendly designs, focusing on energy efficiency and reduced waste. By using recyclable materials, these machines contribute to a circular economy, reducing the environmental footprint of the packaging process.

Selecting the Right Machine for Your Business

Choosing the appropriate cushioning pad manufacturing equipment is crucial for any business looking to invest in its packaging line. Factors such as production volume, material type, and pad specifications should guide the selection process. Alibaba.com serves as a marketplace to connect with suppliers offering a wide array of machines to fit various operational scales and production needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4