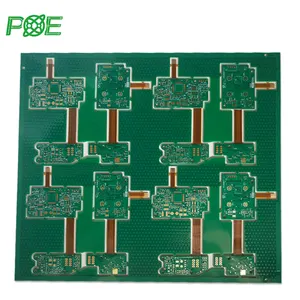

Fpc Connector Circuit Board Pcb Antenna Mobile Phone Fpc And 0 3 Pitch Quantity Gold Copper Oem Customized Item Layer Board

Heavy Copper PCBs, or heavy copper printed circuit boards, are a type of circuit board with copper thicknesses substantially exceeding the standard levels found in more common PCBs. Typically, while a standard PCB has copper thickness around 1 oz/ft² to 2 oz/ft², heavy copper PCBs can boast thicknesses anywhere from 3 oz/ft² to 20 oz/ft² or more. This increased copper content allows the PCB to carry higher currents, withstand extreme thermal strains, and perform reliably in harsh environments.

The primary audiences for heavy copper PCBs are industries that require robust electrical performance and enhanced durability. These include sectors like automotive, power supply, military and defense applications, as well as solar panel manufacturers. For instance, in the automotive industry, heavy copper PCBs are essential for managing the high-power distribution required in electric vehicles.

The working principle of heavy copper PCBs is largely similar to standard PCBs in that they provide paths for the flow of electricity to connect various electrical components. However, due to their increased copper weight, they are capable of handling higher current loads and providing better thermal management. This is achieved by integrating thick copper planes into the board which can conduct heat away from hot spots and distribute it across the board more effectively, thereby reducing the risk of overheating.

In the domain of heavy copper PCBs, there is a spectrum of types to meet various technical requirements and application scenarios:

Single-Sided Heavy Copper PCBs: These are the most basic type, featuring a single layer of conductive material—copper—on one side of the board. They're typically used in simple electronics where minimal component integration is needed and cost-effectiveness is a priority.

Double-Sided Heavy Copper PCBs: These PCBs have conductive copper layers on both sides, allowing for a denser arrangement of circuits. They're commonly employed in more complex devices that require intermediate levels of power and circuitry.

Multilayer Heavy Copper PCBs: These complex boards consist of multiple layers of circuitry stacked together. They provide higher capacity for power distribution and enable sophisticated electrical functions in compact spaces. This makes them ideal for high-tech applications such as computer data centers or industrial automation systems.

Each type serves distinct purposes based on thermal management requirements, electrical performance needs, and physical space constraints.

Selecting the right heavy copper PCB requires understanding both product specifications and application needs. When considering heavy copper PCB options for your business operations or resale purposes, focus on attributes such as copper thickness, layer count, board size, and thermal management capabilities.

Copper thickness is paramount because it defines the current-carrying capacity and thermal resilience of the PCB. Match the thickness to your application's power requirements.

The layer count affects the complexity and functionality of your circuit board. More layers typically allow for more intricate designs but also increase production costs.

Board size should align with your device's dimensions; ensure that your selected heavy copper PCB will fit within your product's housing.

Lastly, consider how effectively a heavy copper PCB can manage heat. Assess if additional cooling methods need to be integrated into your system design alongside the board.

By carefully weighing these factors against your specific use cases and business needs, you can make an informed decision when choosing heavy copper PCBs from the extensive variety available on Alibaba.com.

When sourcing heavy copper PCBs for your business needs, Alibaba.com presents itself as an exceptional marketplace offering a wide selection of products from reliable suppliers worldwide. With its expansive network of sellers providing various types and specifications of heavy copper circuit boards, businesses can easily find options that meet their unique requirements.

Alibaba.com's user-friendly platform simplifies the process of comparing different heavy copper PCB offerings by allowing you to filter search results based on specific needs such as layer count or substrate material. Furthermore, with Trade Assurance service safeguarding your transactions until delivery completion, you can be assured that your investment is protected throughout the procurement process.

The platform's commitment to facilitating global trade seamlessly makes it ideal for businesses seeking tailored solutions for their electronic components. Whether you're looking for high current capacity boards for industrial machinery or robust circuitry for automotive applications, Alibaba.com stands out as a source where you can confidently procure high-quality heavy copper PCBs tailored to your business's operational demands.

A Heavy Copper PCB is a printed circuit board featuring copper conductors with a thickness greater than 3 oz/ft², which allows it to handle higher current levels and provide better thermal management compared to standard PCBs.

Heavy Copper PCBs are commonly used by industries that require durable and high-performance circuitry, such as automotive, power supply, military and defense, and solar energy sectors.

The benefits of using a Heavy Copper PCB include increased current carrying capacity, enhanced thermal dissipation, and greater mechanical strength for handling extreme environmental conditions.

Copper thickness directly impacts the current-carrying capacity and thermal management capability of a Heavy Copper PCB. Thicker copper allows for higher current flows and more effective heat dissipation.

Yes, Heavy Copper PCBs can be engineered to meet the requirements of high-speed applications by incorporating appropriate design features that manage impedance and reduce signal loss.

Designing a Heavy Copper PCB may come with certain limitations, such as increased board weight and challenges in etching fine features due to the thick copper layers.

The choice between single-sided, double-sided, or multilayer Heavy Copper PCBs should be based on your application's complexity, power requirements, and space constraints.

Yes, suppliers on Alibaba.com can often customize Heavy Copper PCBs to meet specific design requirements such as unique shapes, layer configurations, or additional features like plated through-holes.

Heavy Copper PCBs work well with various thermal management solutions including heat sinks, thermal vias, and conductive cooling techniques to manage heat effectively.

Generally, an increased layer count will lead to higher production costs due to the complexity and additional materials required for multilayer Heavy Copper PCB manufacturing.

Multilayer Heavy Copper PCBs are frequently used in complex electronic devices such as computer servers, industrial automation systems, and advanced communication equipment where dense circuitry and robust power distribution are needed.

When selecting a board size for your Heavy Copper PCB, ensure that it fits within your product's housing and that the size supports all necessary components without compromising performance.

Soldering on Heavy Copper PCBs may require special attention due to the high thermal mass; appropriate soldering techniques and equipment might be necessary to achieve strong and reliable joints.

Quality verification can be done by examining supplier certifications, requesting sample boards for evaluation, and checking reviews or ratings from other buyers on Alibaba.com.