Introduction to Nipple Injection Machines

Nipple injection machines are specialized equipment in the field of plastic processing, designed to shape plastic granules into precise dimensions for various applications. These machines are integral to manufacturing processes across industries, from consumer electronics to pharmaceuticals, food and beverage, and the automotive sector. Their robust construction ensures a prolonged service life, meeting the demands of continuous, high-speed production.

Types and Applications

The versatility of nipple injection machines is evident in their ability to produce components for a wide array of products. These machines are adept at creating intricate parts for thin-wall containers, caps, pails, and buckets, as well as PVC pipe fittings. The adaptability of these machines allows them to serve a multitude of sectors, proving their essential role in the packaging industry and beyond.

Features and Materials

Equipped with a special screw design, nipple injection machines enhance plasticizing shot weight and speed, ensuring efficient operation. The clamping force of these machines varies, typically ranging from 2,000 kN to 13,000 kN, which allows them to withstand significant external machining forces. The construction of the steel bush in the clamping unit is engineered to minimize wear resistance and reduce lubrication requirements, thereby offering cost savings on maintenance.

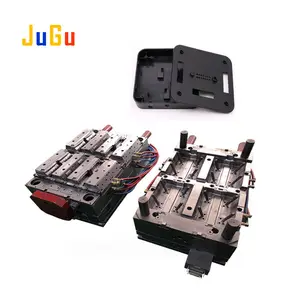

Advantages of Modern Molding Tools

Modern nipple injection machines incorporate a single-cylinder system with a servo-valve, which facilitates a swift response rate in line with industry standards. The precision of these machines is a testament to their design improvements, which aim to limit defective rates significantly. Additionally, the specialized design of these molders ensures that users invest in the exact clamping force needed for their specific applications, enhancing the efficiency of their operations.

Investing in Nipple Injection Machinery

Selecting a nipple injection machine from the array of options available on Alibaba.com means choosing a machine that will transform plastic granules into the required dimensions with improved accuracy. These machines are not only designed for durability but also for precise, industry-standard production. With a focus on design innovation, these machines are a strategic investment for businesses looking to scale their production capabilities in plastic processing.

Choosing the Right Machine

When considering a nipple injection machine, it is crucial to assess the specific needs of your plastic processing business. The machines available through Alibaba.com's listings are provided by leading wholesalers, ensuring a variety of options to suit different sizes of preforms and applications. By browsing the selection, businesses can find the equipment that aligns with their operational requirements and production goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4