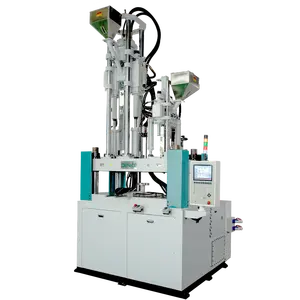

Introduction to Plastic Fruit Basket Injection Moulding Machines

Injection moulding technology has revolutionized the production of plastic items, and among the most versatile equipment in this domain is the plastic fruit basket injection moulding machine. This machinery is pivotal in manufacturing durable and functional plastic fruit baskets, catering to a myriad of industries from food & beverage to consumer goods.

Design and Functionality

The design of a plastic injection moulding machine is focused on efficiency and longevity. These machines are engineered to operate at high speeds, ensuring a swift production cycle for plastic fruit baskets. The incorporation of a single-cylinder system with a servo-valve ensures a consistent and industry-standard response rate during the moulding process.

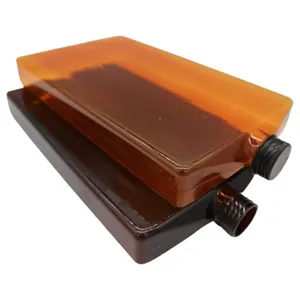

Applications and Versatility

A plastic moulding machine is not limited to creating just fruit baskets. Its versatility extends to various applications such as producing thin-wall containers, PVC pipe fittings, and other packaging solutions. The adaptability of these machines makes them a valuable asset across different sectors, including the automotive and pharmaceutical industries.

Technical Specifications

Technical prowess is at the core of the injection moulding equipment. Machines come with a specialized screw design that enhances the plasticizing shot weight and speed, crucial for creating precise and uniform fruit baskets. The clamping force of these machines can range significantly, allowing them to withstand various external machining forces and cater to different production requirements.

Material and Durability

The materials used in the construction of a fruit basket moulding machine are chosen for their durability and wear resistance. For instance, the steel bush in the clamping unit is designed to minimize wear and reduce the need for lubrication, which can lead to cost savings in maintenance.

Environmental and Cost Efficiency

Modern plastic injection moulding machines are not only designed for performance but also for environmental and cost efficiency. By reducing the need for lubrication and optimizing the use of plastic granules, these machines contribute to more sustainable production practices and lower operational costs.

In conclusion, the plastic fruit basket injection moulding machine stands as a testament to the advancements in plastic production technology, offering a blend of speed, precision, and versatility. For businesses looking to enhance their production capabilities, these machines represent a significant investment in efficiency and quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4