Popular in your industry

Related Searches:

Top categories

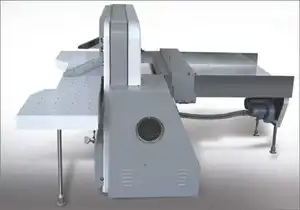

About polar 115 paper cutter machine

In the bustling world of print shops, where precision and efficiency are paramount, the high-performance paper cutter emerges as a game-changer. This cutting-edge tool is not just a piece of equipment; it's the heart of the finishing process, providing unmatched accuracy and speed. As we delve into the capabilities and features of this industrial marvel, we'll explore how it is revolutionizing print shops, enhancing workflow, and setting new standards in paper cutting technology. Join us as we uncover the pivotal role of paper cutters and why this model stands out in this competitive landscape.

Understanding the Role of Paper Cutters in Print Shops

Paper cutters are indispensable tools in print shops, where they serve the critical function of trimming paper to precise dimensions. These devices, which have evolved significantly since their inception in the mid-19th century, are designed to deliver clean and straight cuts, a task that would be laborious and less accurate with manual tools. In a print shop environment, the precision of a paper cutter can directly impact the quality of the finished product.

The design of paper cutters can vary, but they generally consist of a flat surface marked with a grid for alignment, a sharp steel blade for cutting, and a sturdy base. Some models offer additional features such as the ability to make wavy cuts or score paper without fully cutting through it. These features are particularly useful for custom print jobs that require intricate designs or unique finishes.

Industrial paper cutters used in commercial settings are typically more robust, incorporating motorized and automated functions that enhance productivity. They can handle large volumes of material, including paper, cardboard, and other substrates, making them a cornerstone in the operations of a busy print shop. The efficiency of these machines can significantly affect turnaround times and overall workflow, underscoring their role as a vital component in the printing industry.

The High-Performance Paper Cutter: A Synopsis

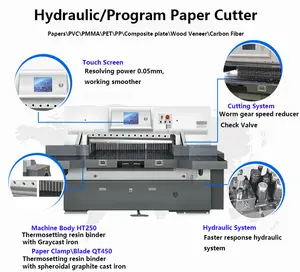

The high-performance cutting system is a robust paper cutter designed to handle a cutting width and depth of 45”. It is equipped with a comprehensive suite of components including a stack lift, jogger with air removing roller, and an automatic unloader. The machine features efficient waste removal, a color touch-screen for easy operation, and safety measures to ensure operator safety. Additional attributes include side tables with air to facilitate paper handling and included accessories such as blades, sticks, tools, and guards. The system is designed to be thoroughly cleaned and tested before shipment, ensuring that it is in full working order and ready for immediate use in a professional setting.

Key Features of the High-Performance Paper Cutter

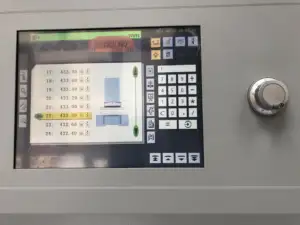

The programmable paper cutter is engineered for consistent performance in single-shift operations. Its hydraulic swing cut mechanism ensures precise cuts with minimal need for adjustments. The cutter's clamping pressure is adjustable, accommodating a variety of cutting materials and enhancing its versatility. Operators can benefit from the bright LED cutting lines that contribute to a safer work environment. The machine's memory capacity is notable, with the ability to store up to 198 programs, which can be easily modified to fit changing job requirements.

In terms of specifications, the cutter boasts a substantial cutting width of 45.27 inches and a feeding height of 6.5 inches, matched with a feeding depth of 45.27 inches. The knife thickness is 0.54 inches, with a maximum grinding reserve of 1.77 inches, allowing for a minimum cut without a false clamp plate of 0.98 inches and with a false clamp plate of 3.74 inches. These specifications underscore the machine's capacity to handle diverse cutting tasks with precision.

From an electrical standpoint, the cutter is equipped with a main drive electric power of 5.5 kW or 7.38 hp, and it can handle a dynamic surcharge of 20%. It operates efficiently on a three-phase AC supply voltage of either 200 V with a 16 A fuse or 400 V with a 16 A fuse, demonstrating its adaptability to various electrical setups. This flexibility ensures that the paper cutter can be integrated into different print shop environments with ease.

Advanced Safety Measures for Operator Protection

The paper cutter incorporates a comprehensive safety concept designed to regularly assess all safety functions of the high-speed cutters. This concept ensures that the machines adhere to stringent safety standards. Regular check-ups are conducted to certify that the equipment is functioning correctly and to identify if any servicing is necessary. These evaluations are crucial for maintaining the integrity of the machine's operation and the protection of the operator. The commitment to safety is evident in the meticulous attention to the maintenance of these cutters, reflecting the importance placed on operator safety and equipment reliability.

Precision and Accuracy: The Cutting Edge

The high-speed cutter exemplifies precision and accuracy with its advanced features designed for optimal cutting performance. Formats with diagonals up to 1,150 mm can be accurately turned on the cutter, ensuring precise alignment and size consistency. The enhanced model enhances this precision through its automatic graphic programming, which facilitates a highly automated cutting process. This is further complemented by the professional model, which offers job-specific programmable parameters and label and distortion correction, allowing for meticulous adjustments and fine-tuning.

Key to the cutter's precision is the array of options aimed at improving the cutting accuracy. The swivel backgauge and tilting backgauge enable precise squareness and correction of overcut or undercut by motorized adjustment. Additionally, the programmable clamping pressure adjustment allows for the correct clamping pressure to be set, which not only contributes to the longevity of the knife but also to the higher cutting precision. The integration of sensors within the table for automatic clamping pressure adjustment further refines this process, ensuring optimum clamping for different materials.

The machine's optimized cutting cycle and the infinitely variable knife speed adjustment cater to a variety of materials, enhancing the cutter's versatility. The feature specifically designed for handling difficult materials ensures that even UV-varnished materials can be cut with precision. These features collectively ensure that the high-speed cutter delivers accurate and consistent results, making it a valuable asset in settings where precision is paramount.

Efficiency and Productivity Benefits

The efficiency of print shops can be significantly enhanced through the integration of automated systems in the finishing process. High-speed cutters are designed to optimize workflow, automate operations, and reduce cycle times, contributing to a more efficient production environment.

The automation of material handling, including stack lifts and loading equipment, alleviates the physical burden on operators and accelerates the production flow. This automation extends to the jogging process, where precision in preparing the cutting material is achieved, ensuring both quality and verifiable quantity.

Moreover, the transportation and buffering of cutting materials are executed with precision and speed, thanks to advanced conveyor units and transfer systems. These systems are engineered to handle even the most substantial reams effortlessly, thereby minimizing fatigue and streamlining the workflow.

In the realm of cutting, high-quality paper cutters stand out with their ability to process a variety of materials with precision. The availability of numerous options allows for customization to meet specific production needs, further enhancing efficiency.

Additionally, the post-cutting processes, such as banding, are optimized for quick setup times and ease of operation, ensuring that even small-sized labels or postcards are processed swiftly and effectively. The integration of networking solutions eliminates setup time by utilizing prepress data, thus streamlining the cutting work and enhancing overall productivity.

Material Compatibility and Versatility

The high-performance paper cutter machine is designed to accommodate a variety of materials, enhancing its versatility in a print shop setting. It is capable of handling formats with large diagonals, which can be easily turned on the cutter, making it suitable for larger sizes that can only be turned on the front table. The machine's compatibility with different materials is further evidenced by its infinitely variable knife speed, which can be adjusted to cater to the cutting requirements of diverse materials, including plastic panels.

Additional features that contribute to the machine's material versatility include a static elimination device, which prevents statically charged waste or plastic films from adhering to the knife, and a special coating on the knife to prevent glue adhesion, thereby maintaining productivity. A feature designed to optimize the cutting of challenging materials, such as UV-varnished surfaces, is also included. Moreover, the machine's separate air control for the front table ensures that cut labels can be easily managed without the risk of them floating away, which is particularly useful when dealing with lightweight or delicate materials.

For operations that involve smaller labels, such as business cards, the machine offers a precision plate, ensuring precision without quality loss. The programmable clamping pressure adjustment allows for the correct clamping pressure to be set in accordance with the material being cut, which not only enhances cutting precision but also extends the knife's service life. These features collectively underscore the machine's ability to handle a broad spectrum of materials, making it a versatile and indispensable asset in any print shop.

Maintenance and Durability: Ensuring Long-Term Performance

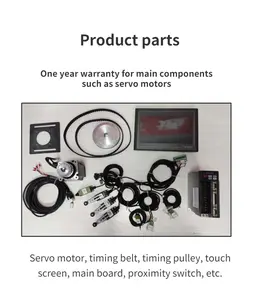

Maintaining the performance of your paper cutter is crucial for the longevity and reliability of your equipment. Regular maintenance is essential to ensure that your machine operates at its best. A precision paper cutter benefits significantly from such attention to detail. Experienced technicians are vital when it comes to diagnosing and addressing any issues that may arise, particularly with cutting precision or mechanical problems. Utilizing approved parts for repairs not only maintains the integrity of the machine but also contributes to its durability. It's important to address equipment issues promptly to avoid costly downtime and to maintain the efficiency of your operations. Moreover, the possibility of upgrading certain components can further enhance the machine's functionality and extend its service life, ensuring that it continues to meet the evolving demands of print shop environments.

Comparative Analysis: High-Quality Paper Cutters vs Other Paper Cutters

When comparing high-quality paper cutters to other industrial paper cutters, it's essential to consider the mechanical design and control systems. High-quality models are known for their robust construction, which contributes to their durability and ability to handle the substantial force exerted during cutting operations. Unlike some lighter models that may use less metal in their construction, the heft of these machines suggests a stable and sturdy machine capable of sustaining rigorous use.

Control systems are another critical factor. High-quality paper cutters feature advanced control systems with intuitive interfaces, often including touch screens, which facilitate ease of use and can be critical for efficient operation. These systems typically allow for software updates via USB or network connections, ensuring the machine remains up-to-date with the latest technology. The compatibility with industry standards also means these cutters can seamlessly integrate data from prepress, streamlining the workflow from design to cutting.

In terms of features, these cutters may offer various table surface options and waste disposal systems like Automatic Waste Removal, which can be particularly beneficial for high-volume environments that deal with numerous trims. Additionally, the availability of auxiliary equipment such as air tables, stack lifts, and joggers can significantly enhance productivity, with some systems improving operator efficiency by an average of 20-25%.

Leveraging Alibaba.com for Your Print Shop Needs

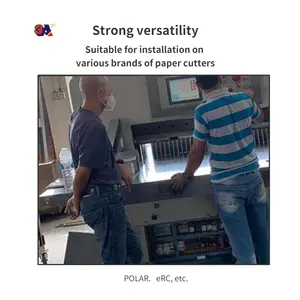

For print shops looking to enhance their operational efficiency, Alibaba.com presents a diverse array of bulk paper cutters, suitable for environments ranging from small boutiques to large-scale industrial settings. The selection includes machines capable of intricate tasks such as embossing, slitting, and folding, as well as machines equipped for printing vibrant colors on napkins and tissues. The versatility of the paper machinery on Alibaba.com extends to producing paper cups and serviettes, highlighting the platform's commitment to providing comprehensive solutions for the paper industry.

The machinery available is engineered to streamline the production process, from the precise embossing of patterns to the meticulous counting and stacking of finished products. This ensures that print shops can maintain a high level of productivity with a consistent output quality. By leveraging the variety of paper cutters on Alibaba.com, print shops can find the right machine that aligns with their specific requirements, whether for intricate designs or bulk processing. The platform's offerings underscore the importance of having reliable and versatile equipment in a print shop's arsenal to stay competitive and efficient in the market.

Conclusion: Investing in the Right Equipment for Maximum Efficiency

The high-performance paper cutter represents the pinnacle of efficiency and precision in the modern print shop. With its robust design, advanced safety measures, and unparalleled precision, it stands as a testament to the importance of investing in quality equipment. This paper cutter not only meets the diverse needs of today's printing industry through its versatility and material compatibility but also ensures long-term performance with its focus on maintenance and durability. When compared to other paper cutters, its superior construction, control systems, and productivity benefits highlight its exceptional value. Furthermore, platforms like our B2B marketplace make accessing such top-tier equipment easier, helping print shops to stay competitive and efficient. In conclusion, this high-performance paper cutter is not just an investment in a machine but an investment in the future of print shop operations, promising a significant return through increased productivity and impeccable quality of work.