Introduction to Rubber Disc Mills

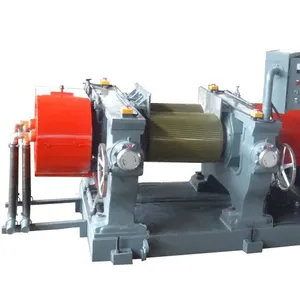

Rubber disc mills are essential equipment in the material processing industry, designed to facilitate the milling of rubber by transforming it into fine, usable particles. These mills are integral to various production lines, catering to both large-scale and small-scale operations. The versatility of rubber disc mills stems from their innovative design, which allows them to be adapted to a multitude of settings and applications.

Types and Applications

The range of rubber disc mills includes several designs, each tailored to meet specific production requirements. From compact models ideal for small enterprises to robust units that serve large manufacturing plants, these mills are adept at handling diverse rubber milling tasks. Their applications span across the production of tires, seals, and gaskets, to the recycling of rubber products, underscoring their importance in sustainable manufacturing practices.

Features and Materials

Constructed from resilient materials, rubber disc mills are built to last. They are engineered to withstand the rigors of milling operations, ensuring longevity and consistent performance. The mills feature user-friendly control panels that simplify operation, minimizing noise levels to create a more comfortable working environment. Their efficient design is focused on reducing energy consumption, which is a crucial factor in operational cost management.

Advantages of Rubber Disc Mills

The advantages of utilizing a rubber disc mill in production are manifold. These mills are designed to enhance efficiency, significantly cutting down on milling time and thereby boosting productivity. The durability of the materials used in their construction translates to a lower frequency of maintenance, ensuring uninterrupted operation and reliability. Additionally, the energy-efficient nature of these mills contributes to lower energy bills, directly impacting the profitability of businesses.

Selection and Purchase Considerations

When selecting a rubber disc mill, it is important to consider the specific milling needs of your operation. The diverse collection available ensures that there is a match for every requirement, from throughput capacity to particle size specifications. Prospective buyers are encouraged to explore the variety of options to find a mill that aligns with their production goals. While browsing, customers will find that the range of mills is designed to cater to a spectrum of budgets and operational scales.

Why Choose a Rubber Disc Mill?

Choosing the right rubber disc mill can be a pivotal decision for businesses looking to optimize their rubber milling processes. These mills are not just machines but investments in efficiency and sustainability. With a focus on reducing energy consumption and maximizing productivity, a well-selected rubber disc mill can be a cornerstone in the pursuit of operational excellence and competitive advantage in the rubber processing industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4