Understanding Submerged Arc Furnaces

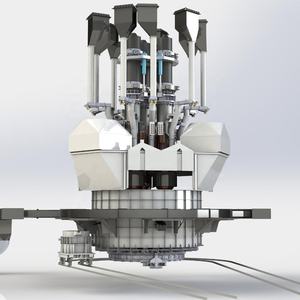

Submerged arc furnaces are industrial equipment designed for the smelting of various metals. These robust machines utilize a reduction smelting process that is essential in metal production. Employing an electric arc submerged in the raw material, they achieve high temperatures necessary for melting a wide array of metals.

Design and Operation

The design of a submerged arc furnace is tailored to ensure efficiency and safety in metal processing. Typically, these furnaces are equipped with a tilting mechanism, allowing for angles up to 95 degrees to facilitate the pouring of molten metal. The operation is managed through a PLC system, ensuring precision and control during the smelting process.

Applications and Versatility

Submerged arc furnaces are versatile, catering to a range of industries. They are pivotal in producing materials for sectors such as automotive, construction, and the manufacturing of home appliances. The adaptability of these furnaces to melt different metals makes them indispensable in various industrial applications.

Features and Materials

Constructed from durable materials, submerged arc furnaces are built to withstand the rigors of industrial use. They incorporate water-cooling systems to manage the high operational temperatures and are designed to resist electrical faults with circuit breakers that ensure the safety of the operation.

Advantages of Submerged Arc Furnaces

The primary advantage of using a submerged arc furnace lies in its efficiency and the quality of metal produced. The controlled environment reduces oxidation, resulting in purer metal output. Additionally, the energy efficiency of these furnaces makes them a preferred choice in metal smelting.

Choosing the Right Submerged Arc Furnace

Selecting the appropriate submerged arc furnace is crucial for meeting specific industrial needs. With a range of capacities, from smaller units to those capable of handling several tons, these furnaces are designed to cater to both light and heavy-duty melting requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4