Introduction to Tie Rod Threading Machines

Tie rod threading machines are specialized pieces of equipment designed for the creation of precise threads on tie rods, which are essential components in various mechanical systems. These machines utilize advanced technology to ensure efficient and accurate threading, catering to the needs of industries that demand precision in fastening and construction elements.

Types and Applications

There are multiple types of tie rod threading machines, including semi-automatic and fully automatic models, each serving distinct applications. Semi-automatic variants offer control and flexibility for small to medium production volumes, while fully automatic machines provide higher efficiency for large-scale operations. These machines are widely used in automotive, construction, and manufacturing sectors for producing robust threaded components.

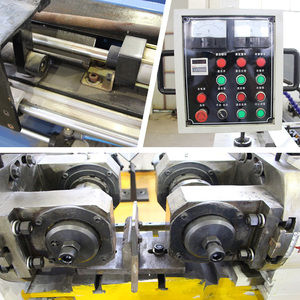

Operational Features

The operational features of a thread rolling machine include variable speed settings that allow for customization according to the threading task. With the integration of electro-hydraulic execution functions, these machines deliver precision in both radial and axial threading processes. The adaptability to various molds makes them suitable for creating not only standard threads but also specialized forms such as abnormal-shape nails and ring shank nails.

Construction and Durability

Constructed with durability in mind, thread rolling die machines are built to resist wear and handle intense production demands without faltering. The robust motor and power distribution systems are designed for longevity, while the gear components undergo high-frequency quenching to ensure resilience during operation. The sturdy build of these machines translates to reliable performance in demanding industrial environments.

Advantages of Modern Threading Equipment

Modern thread rolling machines offer several advantages, such as low noise levels, which allow for operation in noise-sensitive areas without causing disturbances. The self-suction and anti-fouling features of these machines contribute to a cleaner working environment and easier maintenance. Additionally, the anti-vibration properties ensure stability, which is crucial for achieving high-quality threads.

User Experience and Efficiency

Efficiency is at the forefront of the design for automatic thread rolling machines. Users benefit from features like variable speed integration and the ability to switch between semi-automatic and fully automatic modes, tailoring the threading process to specific requirements. The ease of maintenance and the convenience of operation make these machines a valuable asset for businesses looking to streamline their production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4