Introduction to Wood Heat Treatment Equipment

Wood heat treatment equipment is an essential category within the woodworking industry, designed for enhancing the durability and quality of wood. This equipment serves to thermally modify timber, a process that alters the chemical and physical properties of wood, making it more resistant to environmental stressors. The equipment is utilized across various sectors, from furniture manufacturing to construction, ensuring that wood can withstand the rigors of use and time.

Types and Applications

The range of wood heat treatment equipment includes kilns, boilers, and specialized ovens. These systems are employed in processes such as drying, sterilizing, and improving the dimensional stability of wood. Their applications are diverse, supporting industries like carpentry, timber export, and commercial woodworking. Each piece of equipment is tailored to specific treatment requirements, whether for softwood or hardwood species, ensuring adaptability to different wood treatment needs.

Features and Materials

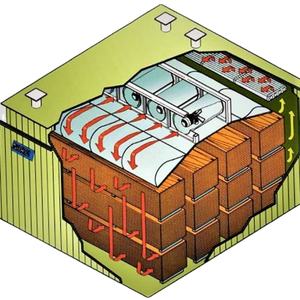

Constructed from robust materials, wood heat treatment equipment is designed to withstand high temperatures and constant use. Features often include advanced thermal controls, energy-efficient designs, and uniform heat distribution systems. These features contribute to the consistent treatment of wood, which is crucial for maintaining the integrity of the final product. The equipment is also designed with safety in mind, incorporating features to protect operators and the work environment.

Advantages of Modern Equipment

Modern wood heat treatment equipment offers several advantages. These include enhanced durability of the treated wood, improved resistance to biological threats like fungi or insects, and reduced environmental impact due to the use of eco-friendly processes. Additionally, the precision offered by contemporary machinery ensures that wood is treated uniformly, resulting in a product that meets stringent industry standards.

Operational Sustainability and Efficiency

The latest models of wood heat treatment equipment are engineered for operational sustainability. They are energy-efficient, reducing the carbon footprint of wood treatment processes. Furthermore, these machines often come with smart-control systems, allowing for precise management of the treatment cycle, which can lead to reduced energy consumption and operational costs.

Choosing the Right Equipment

Selecting the appropriate wood heat treatment equipment is crucial for achieving desired outcomes. It is important to consider the specific requirements of the task at hand, such as the type of wood, the scale of operation, and the desired properties of the treated wood. While Alibaba.com does not endorse any particular brand or manufacturer, the platform offers a comprehensive listing of equipment, enabling buyers to compare different models and features to find the most suitable machinery for their needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4