A small printed circuit board (PCB) is the cornerstone of modern electronics, providing the necessary electrical connections for components in a compact and efficient manner. Alibaba.com offers a diverse range of small PCBs, catering to the varied needs of the electronics industry. These boards are essential for the miniaturization of devices, allowing for sophisticated electronic functionality in increasingly smaller gadgets.

Types and Characteristics of Small PCBs

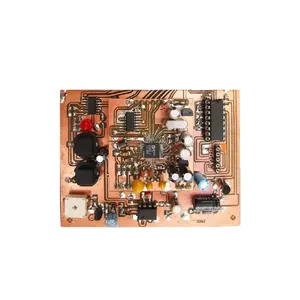

The variety of small PCBs available is vast, with each type offering unique characteristics for different applications. Single-sided PCBs are the most basic type, with components on one side and conductive traces on the other. Double-sided PCBs allow for more complex circuitry by providing lines on both sides of the board. Multilayer PCBs, which can have anywhere from four to twelve layers or more, offer higher functionality and are suitable for complex devices like smartphones and laptops. Flex PCBs, made from flexible materials, are used in applications where the board may need to bend or fold, without breaking. Rigid-flex PCBs combine the best of both worlds, offering the stability of rigid PCBs with the flexibility of flex circuits, ideal for advanced medical devices and military applications. Each type of small pcb board is designed with specific use cases in mind, ensuring that electronic devices of all complexities can be accommodated.

Structure and Components of Small PCBs

The structure of a small circuit board is a marvel of engineering, comprising several layers that include the substrate, copper, solder mask, and silkscreen. The substrate, usually made from FR-4, provides the PCB with its thickness and rigidity. Copper layers are etched with the circuit pattern and can vary in number depending on the complexity of the board. The solder mask, typically green, covers the copper traces and helps prevent electrical shorts. Finally, the silkscreen layer adds labels for component placement. Each component, from resistors to microchips, is strategically placed to optimize the board's operation within its intended electronic device. The interconnectivity between these components is facilitated by vias, which are small holes plated with copper to allow electrical connection between different layers of the PCB.

Materials and Their Properties

The materials used in mini circuit boards are selected for their electrical and mechanical properties. FR-4 glass epoxy is the primary substrate material due to its high dielectric strength, moisture resistance, and thermal stability. Copper is used for its excellent conductivity, and various surface finishes are applied to protect the copper from corrosion and to ensure solderability. Advanced PCBs may use high-frequency materials like Rogers or Teflon when performance at very high frequencies is required. These materials are chosen to ensure the PCB can withstand the operational stresses of its application while providing reliable electrical performance. The choice of material affects the board's durability, signal integrity, and ultimately the longevity of the electronic device it powers.

Business Usages and Applications

Small PCBs are integral to numerous industries, including consumer electronics, medical devices, automotive systems, and aerospace technology. In the consumer sector, they are found in smartphones, laptops, and wearables. Medical devices such as pacemakers and imaging systems rely on small PCBs for their compact size and reliability. In the automotive industry, they are used in engine control units, GPS systems, and entertainment systems. Each application benefits from the miniaturization and customization that small PCBs provide, leading to more efficient designs and better performance in the final products. The versatility of small PCBs also extends to industrial applications, where they are used in control systems and sensors, contributing to the automation and efficiency of manufacturing processes.

Functions and Protection Features

The primary function of small scale pcb manufacturing equipment is to produce PCBs that reliably connect electronic components while fitting into the limited space of modern electronic devices. These PCBs often include protection features such as over-charging prevention and thermal management, which are critical for the safety and longevity of the devices they power. The precise layout and design of the circuits also contribute to the overall functionality, ensuring that each electronic component operates within its intended parameters. Additionally, small PCBs can be designed with built-in test features, allowing for easier troubleshooting and maintenance, which is particularly important in critical applications like aerospace or medical devices.

Features and Unique Selling Points

Small PCBs come with a range of features that set them apart from larger boards. Their compact size is a significant advantage, allowing them to fit into tight spaces without sacrificing functionality. Additionally, the use of surface-mount technology (SMT) enables the mounting of components directly onto the surface of the board, resulting in a more efficient use of space and a reduction in weight. These features make small PCBs ideal for portable and wearable technology, where size and weight are critical considerations. The ability to customize the PCB to the exact specifications of the device it will be used in is another unique selling point, allowing for optimal performance and integration.

Benefits and Positive Outcomes

The benefits of using a small pcb manufacturer are numerous. Small PCBs allow for the creation of smaller, more portable devices, which is a significant advantage in the consumer electronics market. They also enable more complex circuitry, which can lead to enhanced device capabilities. For businesses, the ability to produce small PCBs means quicker prototyping and the ability to respond rapidly to market demands. This agility can provide a competitive edge in fast-paced industries. Moreover, the reduced material usage and waste in small PCB production contribute to more sustainable manufacturing practices.

How to Use and Maintain Small PCBs

Effective use of small pcb boards involves proper integration into the final product, ensuring that all components are correctly soldered and that the board is free from defects. Maintenance requires regular inspection for signs of damage, such as cracks or burns, and cleaning with appropriate solvents to remove contaminants that could lead to short circuits. Proper handling during installation is crucial to prevent damage from electrostatic discharge (ESD). For maintenance, it's recommended to follow the manufacturer's guidelines and use proper tools and techniques to avoid damaging the delicate components and traces on the PCB.

How to Choose and Install Small PCBs

Choosing the right small pcb manufacturing machine involves considering the device's requirements, such as the complexity of the circuit, power needs, and environmental conditions. Installation requires precision; components must be placed accurately, and soldering must be performed without introducing defects. It is often best handled by automated machinery or skilled technicians to ensure the highest quality. When selecting a small PCB, it's also important to consider the manufacturer's reputation for quality and reliability, as well as their ability to provide the necessary technical support.

Target Audience and Meeting Needs

The target audience for small run pcb manufacture includes businesses in the electronics sector that require high precision and customization in their products. Alibaba.com serves this audience by providing access to a wide range of small PCBs that meet various technical specifications. The platform ensures that whether a company is looking for a prototype or full-scale production, they can find a manufacturer that meets their needs. Alibaba.com's vast network of suppliers allows businesses to source PCBs that are tailored to their specific applications, ensuring that the final product meets the exact needs of their target audience.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4