Introduction

Navigating the world of electrical clamp connectors can be a daunting task, given the variety of types, sizes, and specifications available. These essential devices play a crucial role in electrically connecting or disconnecting circuits, making them indispensable in various applications. This comprehensive guide aims to demystify the process of choosing the right electrical clamp connector. We delve into the different types of connectors, their unique features, and the factors to consider when making a selection. We also provide insights on where to purchase these connectors, ensuring you get the best quality and value for your money.

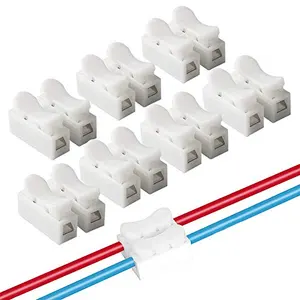

Understanding Electrical Clamp Connectors

Electrical connectors, such as electrical clamp connectors, are devices used for electrically connecting or disconnecting circuits. They can be connected and disconnected manually or with simple tools, eliminating the need for special tools or processes like soldering. Connectors come in various types and structures, but they primarily consist of contacts and a housing. Additional parts may be included depending on the type and use of the connectors. Understanding the basics of connectors can help you choose the right electrical clamp connector for your needs.

Types of Electrical Clamp Connectors

There are several types of electrical clamp connectors. Clamp connectors include chamfered edges for wire protection and stamped lines to show the proper position for crimp dies. They are compliant with branch wire sizes up to 700 mm2. Compression terminals, another type, are highly conductive and used in applications requiring secure connections, compliant with copper stranded wire sizes up to 1600 mm2. Flexible braided connectors, or shunts, are ideal for thermal environments with vibration. Lastly, tubular terminals, also known as sleeves, are made from highly conductive copper and are corrosion-resistant.

Ring Terminals

Ring terminals are a type of electrical clamp connector that are widely used due to their reliability and versatility. They come in different colors like red, blue, and yellow, each insulated in either PVC or Nylon. These connectors are rated for 600 Volts. A unique feature of these ring terminals is their funneled ferrule wire entrance into the electrical barrel, which ensures consistent crimps and reliable wire termination. They can operate in a wide temperature range, from -67°F to 221°F (-55°C to 105°C). These features make ring terminals a preferred choice for many OEMs and electrical contractors.

Spade Terminals

Spade terminals, also known as spade connectors, are a type of electrical clamp connector. They are available in red, blue, and yellow PVC or Nylon insulation, and are rated for 600 Volts. These connectors come in sizes 22-18, 16-14, 12-10 GA/AWG. A unique feature of these spade connectors is the funnel ferrule wire entrance into the electrical barrel, which eliminates wire strand 'hang-up', thereby increasing crimping rates and wire terminal reliability. The operating temperature range for these insulated spade connectors is from -67°F to 221°F (-55°C to 105°C).

Butt Connectors

A butt splice connector is a common and useful connector in electrical work, used to safely terminate or connect wires. It's a type of crimp connector where the wire is inserted and then crimped, usually with pliers, forcing the wire into contact with the metal inside. Some butt splice connectors have heat shrinking ends for a better seal. They are cheap, easy to use, and safer than soldering equipment, making them a vital electrical accessory.

Factors to Consider When Choosing Electrical Clamp Connectors

When choosing electrical clamp connectors, several factors should be considered. Firstly, electrical parameters such as rated voltage and current, and contact resistance are crucial. The connector's safety parameters, including insulation resistance, withstand voltage, and combustibility, are also important. Mechanical parameters like separating force and mechanical life play a role in the selection. The connector's connection modes, installation modes, and appearance should also be taken into account. All these factors ensure the connector's performance, safety, and longevity.

Material and Durability

The compression terminals and clamp connectors available on Alibaba are manufactured using high-quality copper materials, ensuring durability and longevity. The clamp connectors include chamfered edges for protecting the wire, while the compression terminals are highly conductive, ideal for applications requiring secure connections. Also, the tubular terminals, known as sleeves, are made from highly conductive copper, making them resistant to corrosion. This focus on material quality ensures our products can withstand various conditions while maintaining optimal performance.

Size and Compatibility

The clamp connector for non-metallic cable, available in 3/4" and 1" sizes, is a perfect example of the importance of size and compatibility in choosing the right electrical clamp connector. These connectors are designed to connect non-metallic sheathed cable and flexible cord to a steel outlet box or other metal enclosure. The size of the connector should match the size of the cable for a secure and safe connection. Compatibility with the type of cable and the enclosure is also crucial for the effective functioning of the connector.

Ease of Installation

Installing electrical clamp connectors requires precision and the right tools. Start by stripping the insulation from the wire ends, then crimp the connector onto the wire using a suitable crimping tool. Apply enough pressure to create a strong bond between the wire and connector. Once attached, connect it to the appropriate terminal block or component. Protect the connections from moisture and dust by sliding a properly sized heat shrink tubing over the crimped connector and applying heat to shrink it tightly around the connection. Finally, secure the wires using cable ties or clamps to prevent any unintended movement or strain on the connectors.

Price and Quality

Alibaba provides quality and competitively priced products for wire termination. Whether it is new construction, renovation, maintenance, repair, security and home protection system installation, or original equipment manufacturing, Alibaba can efficiently provide the products you need to get the job done.

Safety Standards and Certifications

Safety standards and certifications are crucial when dealing with electrical clamp connectors, especially for high voltage applications. High voltage connectors often require safety certification due to risks such as electric shock, fire, and high temperature rises. These connectors, like terminal blocks, are often used in industrial applications. It's important to refer to the certification requirements of the end equipment to see if individual connector certification is needed. Connectors made from materials with a UL94 rating, which classifies plastics by how they burn, are generally considered safe.

Where to Buy Electrical Clamp Connectors

Alibaba is a responsive online business that provides quality and competitively priced products for wire termination, including electrical clamp connectors. Whether it's for new construction, renovation, maintenance, repair, or original equipment manufacturing, Alibaba can efficiently provide the products you need. They serve contractors, installers, maintenance departments, weekend warriors, and do-it-yourselfers, as well as small to mid-size OEM's. They also offer secure payment methods and delivery services, ensuring a hassle-free shopping experience.

Conclusion

Choosing the right electrical clamp connector is a critical task that requires a thorough understanding of the types available, their features, and the factors to consider for optimal performance and safety. From ring terminals to spade terminals, and butt connectors, each type serves a unique purpose and offers distinct advantages. Considerations such as material and durability, size and compatibility, ease of installation, price and quality, and safety standards and certifications are crucial in making an informed decision. With this comprehensive guide, you're now equipped to make an informed decision when choosing the right electrical clamp connector for your needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4