What are Seam Welders

Seam welders are specialized welding machines designed to produce continuous, airtight welds along the seams of two materials, typically metal sheets or tubes. These machines are integral to industries that require high-quality, uniform welds for products such as pipes, tanks, boilers, and various types of containers. Seam welding is often chosen for its efficiency and the strength it imparts to the final product.

The process of seam welding involves the use of rotating wheels or electrodes that apply pressure and electrical current to the materials being joined. As the wheels rotate and traverse the seam, they generate heat through electrical resistance, causing the material under the electrodes to melt and fuse together. This creates a continuous weld bead that is usually leak-proof and strong. Seam welders can work with a variety of materials including steel, aluminum, and other alloys, making them versatile tools in manufacturing and construction.

The principle behind seam welding is similar to that of spot welding, but instead of creating individual weld spots, seam welding produces a continuous weld along a seam. This is particularly useful for constructing cylindrical or rectangular objects that need to be sealed completely, such as fuel tanks or air ducts.

Seam welders serve a critical role for businesses in sectors such as automotive manufacturing, industrial equipment production, aerospace, shipbuilding, and many others where the integrity of welded joints is paramount. They offer high-speed production capabilities and ensure consistent quality of the welds, which is essential for safety and performance in many applications.

Types of Seam Welders

Seam welders come in various types to suit different applications and materials. Some common types include:

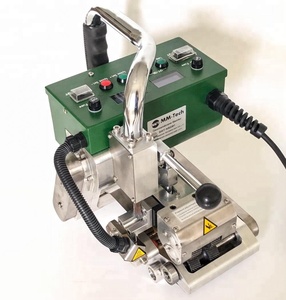

Resistance Seam Welder: This type uses wheel-shaped electrodes that roll along the seam while applying pressure and electrical current, creating a welded joint by heating the material with electrical resistance. It's commonly used for joining thinner metal sheets in applications like drums or tube manufacturing.

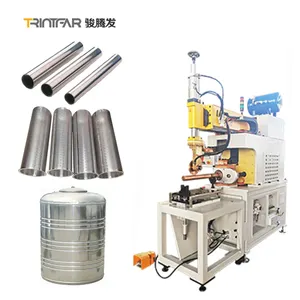

Longitudinal Seam Welder: Designed specifically for producing straight seams, these welders are ideal for joining flat sheets or plates into tubular shapes such as pipes or tanks. They are widely used in industries requiring long, straight welds with high integrity.

Circumferential Seam Welder: Also known as a round seam welder, it is used for producing circumferential seams around cylindrical workpieces. This type is essential for tank fabrication or any application where a continuous circular weld is needed.

Laser Seam Welder: Utilizing high-powered lasers to melt and fuse materials together, laser seam welders offer high precision and speed. They are suitable for delicate or high-tech applications where minimal heat distortion is required.

Each type has its own specific use cases and is chosen based on factors such as the type of material being welded, the required strength of the joint, production speed, and cost-effectiveness.

How to choose Seam Welders

Selecting the right seam welder requires careful consideration of several factors to ensure it meets the specific needs of your business:

Material Compatibility: Ensure that the seam welder can handle the types of materials you plan to join. Different metals have varying electrical conductivity and melting points which can affect the welding process.

Weld Quality: Consider the quality of weld required for your application. Some products may need airtight seams for containing fluids or gases, while others may not have such stringent requirements.

Production Volume: High-volume production may necessitate an automated seam welder with faster welding speeds to keep up with demand. For lower volumes or custom work, a more flexible machine might be appropriate.

Weld Length: The length of the seams you need to produce will determine whether you need a longitudinal or circumferential seam welder—or perhaps both.

Budget: Cost considerations should include not only the initial investment but also operating costs like maintenance and energy consumption.

By taking into account these considerations along with your specific industrial needs—whether you're involved in manufacturing plants or construction works—a suitable seam welder can greatly enhance your production efficiency and product quality.

Best Seam Welders on Alibaba.com

Alibaba.com offers an extensive range of seam welding machines suitable for various industrial applications worldwide. With options available from multiple suppliers across different regions, businesses can find equipment that caters specifically to their requirements. Whether your operation demands precision laser seam welding for high-tech components or robust resistance seam welding for heavy-duty construction materials, Alibaba.com provides access to an array of machines that can be compared easily based on specifications like core components, usage, voltage requirements, and key selling points.

Recognizing that every business has unique needs when it comes to welding equipment, Alibaba.com connects buyers directly with suppliers who can provide customized solutions tailored to specific applications. From small-scale workshops to large manufacturing plants requiring automated welding systems capable of handling high volumes efficiently—diverse businesses can source their ideal solution on this global platform.

Furthermore, purchasing through Alibaba.com is bolstered by services like Trade Assurance which ensures secure transactions and reliable delivery—key considerations when investing in industrial machinery. By facilitating easy communication between buyers and suppliers and providing detailed product information and support services in multiple languages, Alibaba.com asserts itself as a premier destination for securing commercial-grade seam welders that help businesses maintain competitive edges in their respective markets.

Common FAQs for Seam Welders

What is a seam welder?

A seam welder is a welding machine used to create continuous, durable joints by fusing materials along their seam. This is achieved through pressure and heat, typically generated by electrical resistance or laser technology.

Who can benefit from using a seam welder?

Businesses in manufacturing, automotive, aerospace, and construction industries that require high-quality, leak-proof seams for their products can benefit significantly from using seam welders.

How does a seam welder differ from other welding equipment?

Unlike spot welding, which creates single points of contact, seam welders create continuous welds for stronger and more hermetic seals. They are specifically designed for tasks where long, uninterrupted welds are necessary.

Can seam welders handle different types of materials?

Yes, seam welders can handle a variety of materials including steel, aluminum, and other metals. Compatibility depends on the specific type of seam welder and its configuration.

What are the key factors to consider when choosing a seam welder?

When choosing a seam welder, it's important to consider material compatibility, required weld quality and strength, production volume and speed, seam length specifications, and your budget constraints.

How do I know which type of seam welder I need for my business?

The type of seam welder needed depends on the application. Longitudinal seam welders are ideal for straight seams on flat materials, while circumferential seam welders are used for round workpieces. Laser seam welders offer precision for high-tech applications.

Are there automated options available for high-volume production needs?

Yes, there are automated seam welding machines designed to meet high-volume production requirements with consistent quality and increased efficiency.

What after-sales services can I expect with the purchase of a seam welder?

After-sales services vary by supplier but may include online support, video technical support, field maintenance and repair service, or engineers available to service machinery overseas.

How does material thickness affect the choice of a seam welder?

Material thickness influences the amount of power needed for welding and the type of electrodes or laser intensity required. Thicker materials generally need more powerful and robust welding machines.

Can I customize a seam welder to fit my specific needs?

Many suppliers offer customizable options for seam welders to match specific industrial applications such as adjustments in voltage, automation features, or additional safety components.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4