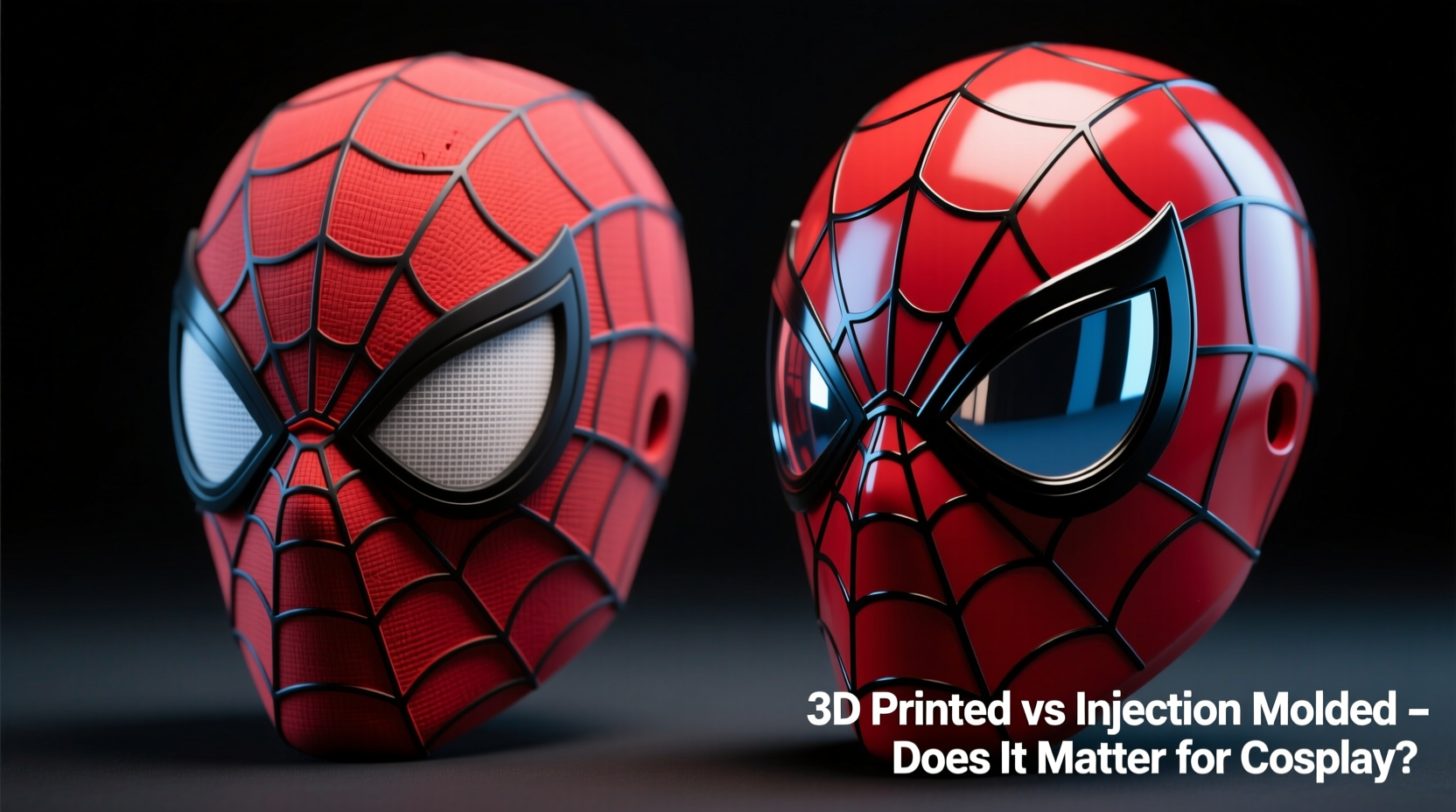

For cosplayers, the mask is often the centerpiece of a superhero costume. Few characters exemplify this more than Spider-Man, whose instantly recognizable red-and-blue face covering defines his look. When building a high-quality Spider-Man cosplay, one of the most critical decisions is choosing between a 3D printed or injection molded mask. While both methods produce wearable replicas, they differ significantly in production, performance, and practicality. The choice isn’t just about aesthetics—it affects comfort, durability, and even how authentic your portrayal feels at conventions or photo shoots.

The rise of accessible 3D printing has made custom masks more attainable than ever, while injection molding remains a staple in commercial prop manufacturing. But does the average cosplayer truly benefit from one over the other? Or are the differences negligible once the mask is on your face under convention lighting?

Understanding the Manufacturing Methods

Before comparing outcomes, it’s essential to understand how each mask type is made.

3D printed masks are built layer by layer using thermoplastic materials like PLA, ABS, or resin. Designers create digital models (often sourced from public repositories or commissioned artists), which are then sliced into printable layers and produced on a desktop or industrial 3D printer. This method allows for extreme customization—adjusting eye slits, adding ventilation, or modifying fit based on head measurements.

Injection molded masks, on the other hand, are mass-produced. A mold is created from a master model (usually sculpted or 3D designed), and liquid plastic—typically PVC or polyurethane—is injected under pressure. Once cooled, the mask is ejected, trimmed, and finished. This process is ideal for consistent, high-volume output but requires significant upfront investment in tooling.

“Injection molding excels in consistency and surface finish, but 3D printing wins in flexibility and accessibility.” — Derek Lin, Prop Fabrication Engineer at HeroProps Studio

Comparative Analysis: Key Factors for Cosplayers

To determine which method suits your needs, consider five core aspects: detail fidelity, structural integrity, comfort, production time, and cost.

| Feature | 3D Printed Mask | Injection Molded Mask |

|---|---|---|

| Surface Detail | Visible layer lines; may require sanding and coating | Smooth, seamless finish out of the mold |

| Durability | Moderate; prone to cracking under impact | High; flexible yet impact-resistant |

| Custom Fit | Highly customizable per print | One-size-fits-most; limited adjustability |

| Production Time | Hours to days per unit | Minutes per unit after mold creation |

| Upfront Cost | Low to moderate (printer + filament) | Very high (mold can cost $5,000+) |

| Breathability/Ventilation | Can be integrated into design | Fixed; depends on original mold |

Real-World Use Case: Alex’s Convention Build

Alex Rivera, a dedicated cosplayer from Austin, TX, faced this exact decision when preparing for Dragon Con. His goal was a screen-accurate Miles Morales Spider-Man mask that would withstand long wear, photo ops, and Texas heat.

He initially purchased an off-the-shelf injection molded mask from a popular vendor. While the finish was flawless and the material soft against the skin, the fit was too tight behind the ears, causing discomfort after two hours. The eye openings were also slightly misaligned with his vision, forcing him to tilt his head during interactions.

Undeterred, Alex downloaded a high-resolution 3D model and modified it using Blender—widening the ear zones, lowering the chin line, and adding small vent holes near the nose. After three test prints and some acetone smoothing, he achieved a lightweight, breathable mask that fit like a second skin. Though it required primer and paint to hide layer lines, the end result earned praise at the event and lasted through multiple wears.

His experience illustrates a key truth: for individual cosplayers, customization often outweighs factory-perfect finishes.

Step-by-Step Guide: Choosing the Right Mask for You

- Define your priorities: Are you aiming for absolute accuracy, comfort, or budget efficiency?

- Evaluate your skills: Can you modify 3D models or do post-processing (sanding, painting)? If not, a pre-made molded mask may save time.

- Check availability: Injection molded masks are sold by specialty retailers (e.g., Trick or Treat Studios), but may not exist for newer or alternate versions of Spider-Man.

- Test fit options: For 3D printed designs, check user reviews or community forums (like Reddit’s r/Cosplay or Thingiverse) for feedback on sizing.

- Budget accordingly: Factor in material costs, printer maintenance, or shipping fees for pre-made masks.

- Consider longevity: Will you reuse the mask for future events? A well-finished 3D print can last years with care.

When Does the Difference Really Matter?

In casual settings—a local comic shop meetup or a quick photoshoot—the distinction between 3D printed and injection molded masks may go unnoticed. Lighting, makeup, and overall costume integration play larger roles in perceived authenticity.

However, in competitive cosplay circuits or professional photography, details matter. Judges notice inconsistencies in symmetry, texture, and finish. Here, injection molded masks have an edge due to their uniform surfaces and lack of print artifacts. That said, skilled crafters can polish and paint a 3D printed mask to near-injection quality—sometimes indistinguishable upon inspection.

Comfort during extended wear is another differentiator. Injection molded masks often use softer, flexible plastics that conform gently to facial movement. 3D printed versions, especially in rigid materials like PLA, can feel stiff and cause pressure points unless carefully designed.

Frequently Asked Questions

Can I paint a 3D printed mask to look like an injection molded one?

Yes. With proper sanding, priming, and painting techniques, a 3D printed mask can achieve a smooth, professional finish. Using fillers like Bondo or automotive putty helps minimize layer lines before applying primer and top coats.

Are injection molded masks worth the higher price?

If you value plug-and-play quality, accurate proportions, and don’t want to spend time on finishing, yes. They typically range from $80–$150, compared to $20–$50 in materials for a 3D printed version. However, the latter offers far greater personalization.

Is one type safer to wear?

Safety depends more on design than manufacturing method. Both types must include adequate ventilation and unobstructed vision. Avoid fully sealed designs. Always test-wear any mask for at least 30 minutes before public use to assess breathability and comfort.

Final Verdict: It Depends on Your Goals

Does the difference between 3D printed and injection molded Spider-Man masks really matter? For collectors or screen-matched builders, yes—material behavior, surface quality, and fit precision influence realism. But for most cosplayers, the answer lies in intent.

If you're crafting for fun, learning, or personal expression, 3D printing offers unmatched creative control. You can iterate, improve, and tailor every aspect to your face and preferences. If you're short on time, lack tools, or prioritize show-ready polish without effort, a professionally injection molded mask is the smarter shortcut.

The best choice isn't universally one or the other—it's the one that aligns with your skill level, timeline, and passion for the craft.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?