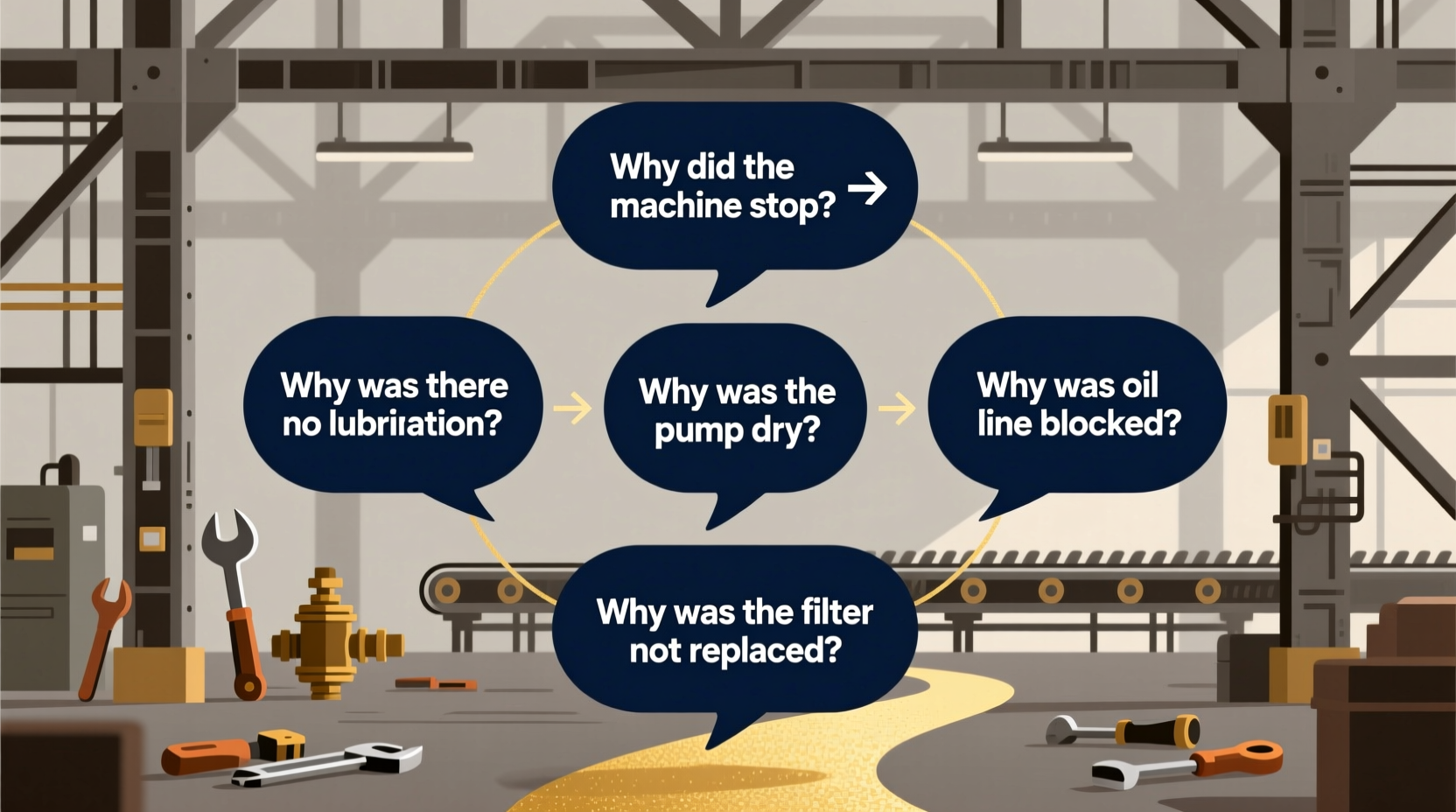

When a problem arises—whether it’s a production delay, customer complaint, or recurring error—the instinctive response is often to fix the symptoms. But without addressing the underlying cause, the same issue will likely return. The 5 Whys technique offers a structured yet simple way to dig beneath surface-level problems and identify their true origin. Developed within the Toyota Production System, this method has since become a cornerstone of lean management, quality control, and continuous improvement across industries.

The power of the 5 Whys lies not in its complexity but in its clarity. By repeatedly asking “Why?”—typically five times—it guides teams through layers of causality until they reach a fundamental cause. When applied correctly, it transforms reactive troubleshooting into proactive prevention.

Understanding the Origins and Purpose of the 5 Whys

The 5 Whys technique was pioneered by Sakichi Toyoda, founder of Toyota Industries, and later refined by Taiichi Ohno, the architect of the Toyota Production System. Ohno described the method as one of the most basic tools for root cause analysis, emphasizing that “by repeating why five times, the nature of the problem as well as its solution becomes clear.”

At its core, the 5 Whys challenges assumptions. It prevents premature conclusions by forcing inquiry beyond the immediate trigger of an incident. For example, if a machine stops working, the first answer might be “the fuse blew.” While technically correct, that doesn’t explain why the fuse blew—or how to prevent it from happening again.

“Toyota has a 'go and see' philosophy. We look at the shop floor and ask why something is occurring, and we keep asking until we get to the root cause.” — Taiichi Ohno, Father of the Toyota Production System

The goal isn't just to assign blame or log an incident, but to create systems that are more resilient. This mindset shift—from symptom management to systemic improvement—is what makes the 5 Whys so enduring.

How the 5 Whys Works: A Step-by-Step Guide

Applying the 5 Whys requires discipline and objectivity. Follow these steps to conduct an effective root cause analysis:

- Define the Problem Clearly: Start with a specific, observable issue. Avoid vague statements like “performance is poor.” Instead, use precise descriptions such as “Order processing time increased by 40% last week.”

- Ask 'Why?' for the First Time: Identify the direct cause of the problem. Base answers on evidence, not speculation.

- Repeat the Question: For each answer, ask “Why?” again. Continue peeling back layers until you reach a root cause—typically around the fifth iteration.

- Validate Each Cause: Ensure every “why” is supported by data or firsthand observation. If an answer lacks proof, investigate further.

- Identify Corrective Actions: Once the root cause is confirmed, develop actionable solutions that address it directly.

Real-World Application: A Mini Case Study

Consider a software company experiencing frequent customer complaints about login failures. The support team logs dozens of tickets per day, and temporary fixes only provide short-term relief.

Using the 5 Whys, the engineering team investigates:

- Why? Users cannot log in. → Because the authentication server times out.

- Why? The server times out. → Because it receives too many requests during peak hours.

- Why? It receives excessive requests. → Because failed login attempts aren’t being cached or throttled.

- Why? There’s no rate-limiting mechanism. → Because the security module was never updated after the user base grew tenfold.

- Why? The module wasn’t updated. → Because there was no process for reviewing infrastructure scalability quarterly.

The root cause: lack of scheduled system reviews. The solution? Implement quarterly architecture audits and automated monitoring alerts. Within two months, login failure reports dropped by 90%. This case illustrates how a technical symptom led to an organizational process gap—one that wouldn’t have been found without persistent questioning.

Common Pitfalls and How to Avoid Them

Despite its simplicity, the 5 Whys can go wrong when misapplied. Below is a comparison of best practices versus common mistakes:

| Do’s | Don’ts |

|---|---|

| Base answers on facts and data | Rely on assumptions or opinions |

| Involve people who understand the process | Let managers guess without frontline input |

| Stop when a systemic cause is found (e.g., policy, design flaw) | Stop at human error without asking why the error was possible |

| Use the 5 Whys for moderate-complexity issues | Apply it to highly technical or multi-factorial problems without additional tools |

One frequent error is stopping too early. Saying “The employee forgot the procedure” may feel like an explanation, but it’s rarely the end of the story. Why was the procedure easy to forget? Was training inadequate? Was the interface confusing? Blaming individuals without examining system design undermines both morale and long-term improvement.

When to Combine the 5 Whys with Other Tools

The 5 Whys excels in straightforward scenarios where cause-and-effect chains are relatively linear. However, complex problems—especially those involving multiple variables or safety risks—benefit from combining it with other methods.

- Fishbone (Ishikawa) Diagrams: Use these to brainstorm potential causes across categories (people, process, equipment, environment), then apply the 5 Whys to each branch.

- Pareto Analysis: Identify which types of failures occur most frequently before diving into root cause analysis.

- Failure Mode and Effects Analysis (FMEA): For high-risk processes, use FMEA proactively, then validate findings with 5 Whys after incidents occur.

In healthcare, for instance, a hospital might use the 5 Whys after a medication error, but pair it with a fishbone diagram to explore contributing factors like staffing levels, labeling practices, and electronic health record design.

Checklist: Conducting an Effective 5 Whys Session

Before leading or participating in a 5 Whys analysis, ensure you’re prepared:

- ☑ Gather a cross-functional team familiar with the process

- ☑ Define the problem using measurable terms

- ☑ Collect relevant data (logs, timelines, error reports)

- ☑ Ask “Why?” iteratively, ensuring each answer leads logically to the next

- ☑ Stop when you reach a process, system, or policy failure—not just human error

- ☑ Document the chain of causality and proposed corrective actions

- ☑ Assign owners and deadlines for implementing solutions

- ☑ Follow up to verify the fix worked

FAQ

Do you always need to ask “Why?” exactly five times?

No. The number five is a guideline, not a rule. Some issues resolve in three steps; others may take seven. The goal is to reach a root cause, not hit a count.

Can the 5 Whys be used in personal life or non-business settings?

Absolutely. Parents might use it to understand why a child refuses homework (“Why?” → Too hard. “Why?” → Didn’t understand the lesson. “Why?” → Missed class due to illness). It works anywhere cause-and-effect reasoning applies.

What if there are multiple root causes?

Some problems have parallel causes. In such cases, run separate 5 Whys chains for each major branch. Alternatively, start with a fishbone diagram to disentangle contributing factors before drilling down.

Making the 5 Whys a Habit for Continuous Improvement

Mastering the 5 Whys isn’t about completing an occasional exercise—it’s about cultivating a culture of inquiry. Organizations that embed this practice into daily stand-ups, post-mortems, and performance reviews move faster from firefighting to forward-thinking.

Start small. After the next minor setback—a missed deadline, a customer complaint, a bug in code—gather your team and ask the first “Why?” Then keep going. Encourage curiosity over blame. Reward those who question the status quo.

Over time, the 5 Whys becomes less of a tool and more of a mindset: a commitment to understanding, learning, and building systems that work not just today, but tomorrow.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?