The 5 Whys technique is a cornerstone of root cause analysis, widely used in lean manufacturing, healthcare, project management, and quality assurance. Developed by Sakichi Toyoda at Toyota Motor Corporation, this method drills down into the underlying causes of problems by repeatedly asking “why” until the core issue is revealed. A well-structured 5 Whys template in PowerPoint (PPT) format can streamline problem-solving sessions, enhance team collaboration, and ensure consistent documentation. This article provides actionable insights, practical templates, real-world examples, and downloadable guidance to help professionals implement the 5 Whys effectively.

Understanding the 5 Whys Methodology

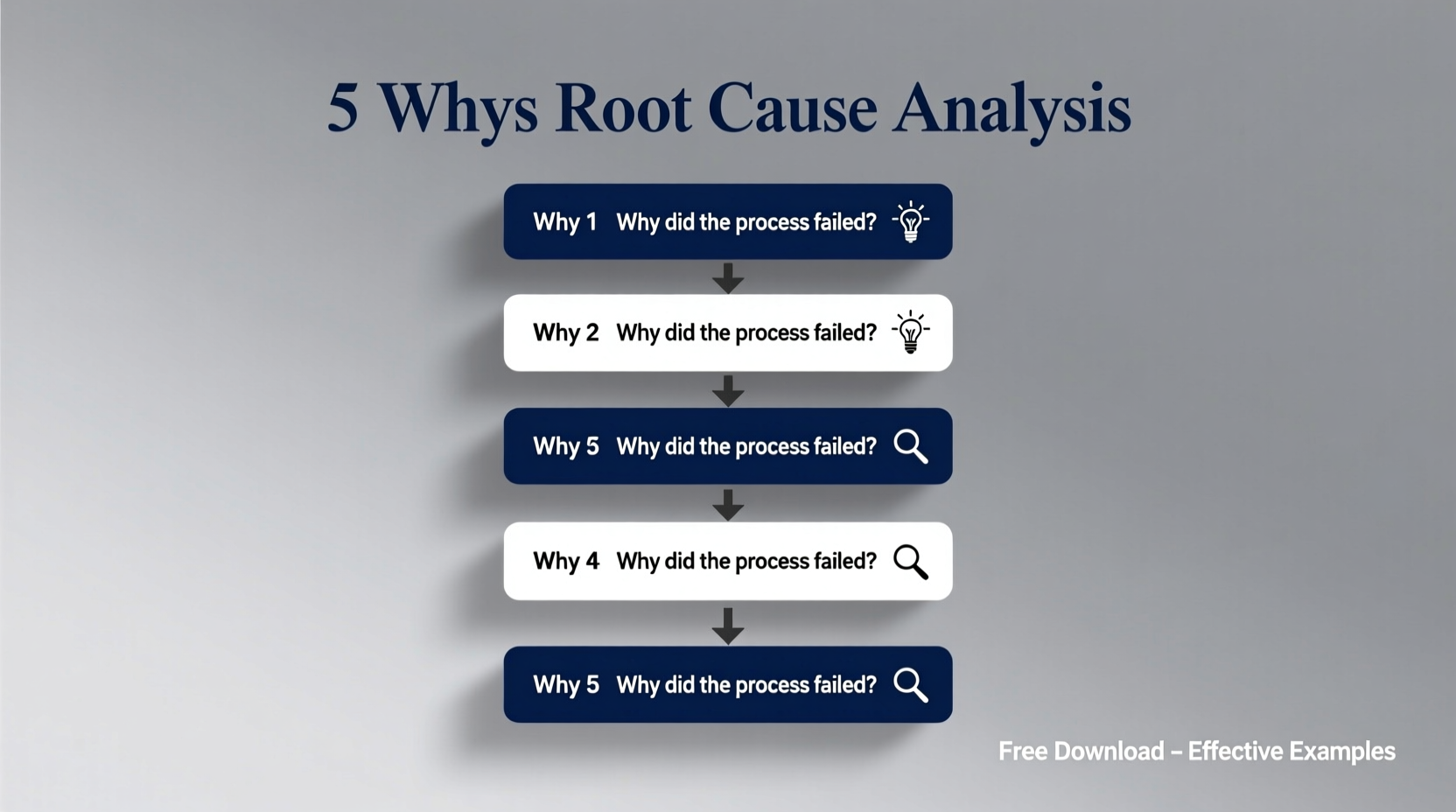

The 5 Whys is deceptively simple: when a problem occurs, ask “why” five times to peel back layers of symptoms and expose the root cause. While the number five is conventional, the actual number of iterations may vary—sometimes four, sometimes seven—depending on the complexity of the issue.

This method works best for problems with a single root cause or tightly linked causal chains. It avoids over-reliance on data analytics during initial investigations, promoting intuitive thinking grounded in process knowledge. When facilitated properly, it encourages teams to move beyond blame and focus on systemic improvements.

“People don’t fail; processes do. The 5 Whys helps us see where the system broke.” — Taiichi Ohno, Father of the Toyota Production System

When to Use the 5 Whys

- Recurring operational issues (e.g., machine downtime)

- Customer complaints about product quality

- Project delays or missed deadlines

- Safety incidents or near-misses

- Service delivery failures in healthcare or IT

Step-by-Step Guide to Conducting a 5 Whys Analysis

A successful 5 Whys session requires structure and discipline. Follow this timeline to ensure clarity and effectiveness:

- Define the Problem Clearly: Write a concise statement describing the issue. Avoid vague terms like “poor performance” or “bad service.” Instead, use specifics: “The packaging line stopped for 45 minutes at 2:15 PM on June 5.”

- Gather the Right Team: Include individuals from different roles involved in the process. Diversity of perspective improves accuracy.

- Ask 'Why?' Iteratively: For each answer, ask why again. Ensure responses are based on facts, not assumptions.

- Identify the Root Cause: Stop when further questioning no longer reveals deeper systemic issues. The true root cause should be something you can act upon.

- Develop Corrective Actions: Assign responsibilities and timelines to prevent recurrence.

- Document and Share: Use a standardized 5 Whys PPT template to record findings and present to stakeholders.

Example Timeline of a 5 Whys Session

| Time | Activity |

|---|---|

| 9:00–9:10 AM | Problem definition and team briefing |

| 9:10–9:30 AM | First three “whys” explored |

| 9:30–9:45 AM | Final two “whys,” root cause identified |

| 9:45–10:00 AM | Action planning and assignment |

| 10:00–10:15 AM | Template completion and review |

Free 5 Whys Template PPT Downloads and How to Use Them

Using a professionally designed 5 Whys PowerPoint template saves time, ensures consistency, and enhances presentation quality. Many organizations offer free downloadable PPTs tailored for root cause analysis. These typically include:

- Clean slide layouts with placeholders for problem statements

- Visual flowcharts showing the chain of causality

- Dedicated sections for corrective actions and responsible parties

- Customizable icons and color schemes for branding

Recommended Free Sources

- ASQ (American Society for Quality): Offers industry-standard templates aligned with Six Sigma practices.

- Canva: Provides user-friendly, visually appealing 5 Whys slides that can be exported to PPT.

- SlideHunter and FPPT: Host community-uploaded templates—review ratings before downloading.

Once downloaded, customize the template by adding your company logo, adjusting colors, and inserting real data. Use animation sparingly to reveal each “why” sequentially during presentations.

Effective Examples of 5 Whys in Practice

Manufacturing: Machine Downtime

Problem: CNC machine stopped working mid-shift.

- Why? The circuit breaker tripped.

- Why? The motor was overloaded.

- Why? Insufficient lubrication caused excessive friction.

- Why? Oil levels weren’t checked during routine maintenance.

- Why? Maintenance checklist did not include lubrication verification.

Root Cause: Incomplete preventive maintenance checklist.

Corrective Action: Revise checklist and train technicians on updated procedures.

Healthcare: Patient Medication Error

Problem: Patient received incorrect dosage of medication.

- Why? Nurse administered the wrong concentration.

- Why? Two similar-looking vials were stored together.

- Why? Storage protocol wasn't followed.

- Why? Staff were unaware of updated labeling guidelines.

- Why? No formal training session was conducted after policy update.

Root Cause: Lack of training on revised safety protocols.

Corrective Action: Implement mandatory quarterly training and reorganize storage cabinets.

“In healthcare, every ‘why’ brings us closer to preventing harm.” — Dr. Lucinda Grande, Patient Safety Advocate

Checklist for Successful 5 Whys Implementation

Use this checklist before, during, and after your next 5 Whys session to maximize impact:

- ✅ Define the problem using specific, measurable terms

- ✅ Involve cross-functional team members familiar with the process

- ✅ Base answers on evidence, not opinion

- ✅ Limit scope to one primary problem per session

- ✅ Identify actionable root causes (not just symptoms)

- ✅ Assign owners and deadlines for corrective actions

- ✅ Document results using a standardized 5 Whys PPT template

- ✅ Review effectiveness of solutions after 30 days

Common Pitfalls and How to Avoid Them

Despite its simplicity, the 5 Whys can go wrong without proper facilitation. Below is a comparison of best practices versus common mistakes.

| Do’s | Don’ts |

|---|---|

| Focus on processes, not people | Blame individuals for failures |

| Stop when you reach an actionable root cause | Continue asking why indefinitely without resolution |

| Validate each answer with data or observation | Accept assumptions as truth |

| Use visual aids like fishbone diagrams alongside 5 Whys | Rely solely on verbal discussion without documentation |

| Follow up on corrective actions | End the meeting without accountability measures |

FAQ

Can the 5 Whys be used for complex, multi-faceted problems?

While the 5 Whys works well for linear problems, complex issues with multiple root causes may require complementary tools like Fishbone (Ishikawa) diagrams or Failure Mode and Effects Analysis (FMEA). However, breaking the problem into smaller components allows the 5 Whys to still play a valuable role.

Is there a digital version of the 5 Whys template?

Yes. Many teams use collaborative platforms like Miro, Lucidchart, or Microsoft Whiteboard to run interactive 5 Whys sessions online. You can also convert a PPT template into a reusable digital form using Google Slides or Notion databases.

How long should a 5 Whys session take?

Most sessions last between 30 to 60 minutes. If it takes longer, consider whether the problem is too broad or if the team lacks sufficient information. Break large problems into sub-issues for focused analysis.

Conclusion and Call to Action

Mastery of the 5 Whys technique transforms how organizations respond to challenges—from reactive fixes to proactive prevention. With free 5 Whys template PPT downloads, clear examples, and disciplined application, teams across industries can uncover hidden inefficiencies and drive meaningful change. Don’t let recurring problems drain productivity or compromise quality. Download a trusted template today, conduct your first session, and start building a culture of continuous improvement.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?