Beetroot has long been recognized for its rich nutritional profile and vibrant color, but few realize it also contains a significant amount of natural sucrose—up to 8–10% by weight in some varieties. While commercial sugar production relies heavily on sugarcane and sugar beets processed in industrial facilities, it is entirely possible to extract edible sugar from beetroot safely and sustainably at home. This guide walks through the science, tools, and practical steps needed to transform raw beets into a pure, unrefined sweetener suitable for cooking, baking, or preserving.

Unlike refined white sugar, beet-derived sugar retains trace minerals like iron, potassium, and magnesium, offering a slightly earthy flavor and golden hue. The process requires patience and attention to detail, but with common kitchen equipment and careful temperature control, you can produce a natural alternative to store-bought sugar—free from additives and environmentally taxing supply chains.

The Science Behind Beet Sugar Extraction

Sugar in beetroot exists primarily as sucrose stored within the plant’s vascular tissue. When sliced and soaked, this sucrose dissolves into water, forming a sugar-rich solution known as \"beet juice.\" Through evaporation and crystallization, the liquid can be concentrated into granulated sugar. The key challenge lies in separating impurities—such as proteins, fibers, and pigments—without chemical clarification agents used in industrial processing.

Home extraction relies on physical methods: diffusion (soaking), filtration, and slow evaporation. Unlike factory systems that use lime and carbon dioxide for purification, household techniques depend on repeated straining and controlled heating to achieve clarity and purity.

“While home-extracted beet sugar won’t match the whiteness of commercial products, it offers a wholesome, minimally processed sweetener with a lower environmental footprint.” — Dr. Lena Torres, Food Scientist & Sustainable Agriculture Researcher

Essential Tools and Ingredients

To begin, gather the following materials. Most are standard kitchen items, making this process accessible even without specialized equipment.

- Organic red beetroots (3–5 lbs for a meaningful yield)

- Stainless steel knife and cutting board

- Large glass or ceramic bowl (non-reactive)

- Cheesecloth or fine mesh strainer

- Stainless steel or enamel-coated pot (avoid aluminum)

- Wooden spoon

- Baking sheet or dehydrator tray

- Parchment paper

- Blender or food processor (optional, for final texture)

- Storage jars with airtight lids

- Distilled or filtered water (to prevent mineral interference)

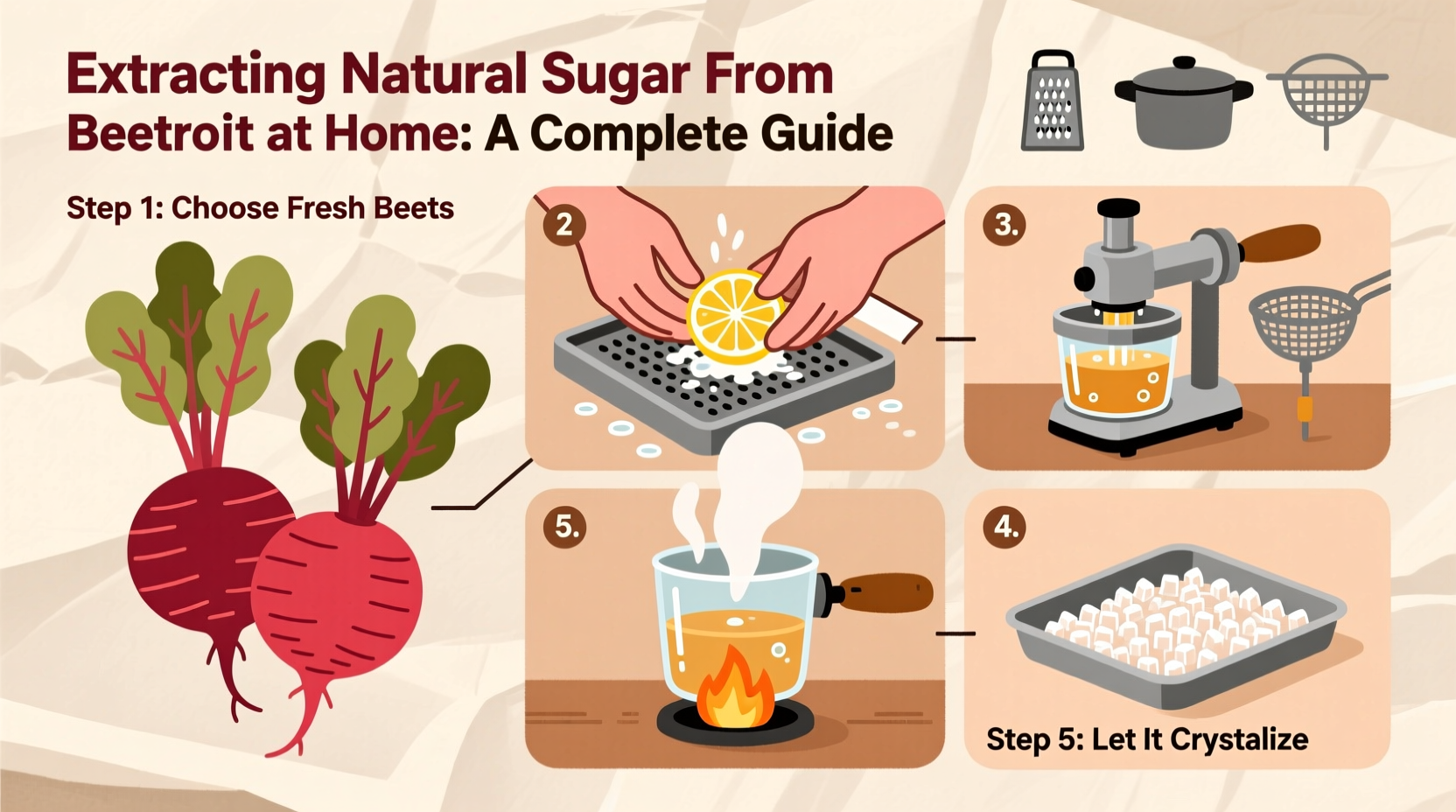

Step-by-Step Extraction Process

- Wash and peel the beets: Scrub thoroughly under running water to remove soil. Peel using a vegetable peeler or knife to eliminate outer layers containing dirt and waxes.

- Slice thinly: Cut beets into uniform 1/8-inch slices to maximize surface area for efficient sugar diffusion.

- Soak in warm water: Place slices in a large bowl with 4 cups of distilled water heated to about 120°F (49°C). Soak for 4–6 hours or overnight. This draws out sucrose without promoting bacterial growth.

- Strain the liquid: Pour the mixture through cheesecloth into a clean pot. Squeeze gently to extract all liquid. Discard solids or compost them.

- First boil and skim: Heat the liquid over medium-low heat. As it warms, foam will rise—this contains proteins and pigments. Skim carefully with a spoon and discard.

- Reduce slowly: Continue simmering uncovered for 2–3 hours, stirring occasionally. The goal is to concentrate the syrup to a honey-like consistency (~65–70% sugar concentration).

- Cool and crystallize: Pour the thick syrup onto a parchment-lined baking sheet. Allow it to cool at room temperature for 12–24 hours. Crystals will begin to form as moisture evaporates.

- Break and dry: Once semi-solid, break the mass into small chunks. Spread on the tray and let air-dry for another 24–48 hours, or use a dehydrator at 95°F (35°C) to speed up drying.

- Grind and store: Pulse dried crystals in a blender until desired grain size is reached. Store in an airtight container away from light and moisture.

Do’s and Don’ts of Homemade Beet Sugar Production

| Do’s | Don’ts |

|---|---|

| Use non-reactive cookware to avoid metallic taste | Boil aggressively—this causes caramelization and darkening |

| Skim foam regularly during reduction | Leave syrup unattended—burning ruins the batch |

| Dry crystals completely before grinding | Store in humid environments—clumping occurs quickly |

| Label and date your sugar batches | Expect pure white sugar—natural color varies from amber to brown |

Real-World Example: A Small-Scale Kitchen Experiment

In rural Vermont, homesteader Miriam Reed began experimenting with beet sugar after growing surplus beets in her garden. With no access to cane sugar and concerns about commercial processing, she adapted traditional European methods using only a stove, glass jars, and reusable cloth filters. Over three seasons, she refined her technique, discovering that soaking at lukewarm temperatures yielded clearer syrup than boiling raw slices. Her current method produces about 1/2 cup of usable sugar per 4 pounds of beets. She uses it in apple preserves, whole-grain breads, and herbal teas. “It’s not just about sweetness,” she says. “It’s about closing the loop—growing, harvesting, and transforming food entirely at home.”

Maximizing Yield and Quality: Expert Tips

- Pre-soak at optimal temperature: Water between 110°F and 130°F efficiently extracts sucrose while minimizing breakdown of sugars.

- Double-strain the juice: After initial filtering, strain again through a coffee filter to remove fine particulates that cloud the final product.

- Control evaporation rate: A wide, shallow pan increases surface area and speeds evaporation without overheating edges.

- Test concentration: Use the cold-water test—drop syrup into chilled water. If it forms a soft ball, it’s ready for crystallization.

- Recycle beet pulp: Mix leftover pulp into soups, veggie burgers, or compost to reduce waste.

Frequently Asked Questions

Can I make liquid beet syrup instead of crystals?

Yes. Stop the reduction process earlier—when the syrup coats the back of a spoon—and bottle it after cooling. Refrigerate and use within 3 weeks. It works well as a pancake topping or glaze.

Is homemade beet sugar healthier than white sugar?

It contains trace nutrients and lacks chemical bleaching agents, but calorically and metabolically, it behaves similarly to regular sugar. Moderation is still essential, especially for diabetics.

Why isn’t my sugar crystallizing?

This usually happens if the syrup wasn’t reduced enough or cooled too quickly. Try reheating and reducing further, then allow slow, undisturbed cooling. Adding a tiny seed crystal can also initiate formation.

Conclusion: Embrace Natural Sweetness at Home

Extracting sugar from beetroot is more than a DIY curiosity—it’s a step toward greater self-reliance and mindful consumption. While the yield is modest compared to industrial output, the satisfaction of creating a pantry staple from garden-grown ingredients is unmatched. Each batch connects you to centuries of agricultural tradition and empowers you to control what goes into your food.

Start small, refine your method over time, and consider integrating beet sugar into seasonal preserves or holiday baking. Share your results, experiment with ratios, and rediscover the subtle richness of truly natural sweetness.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?