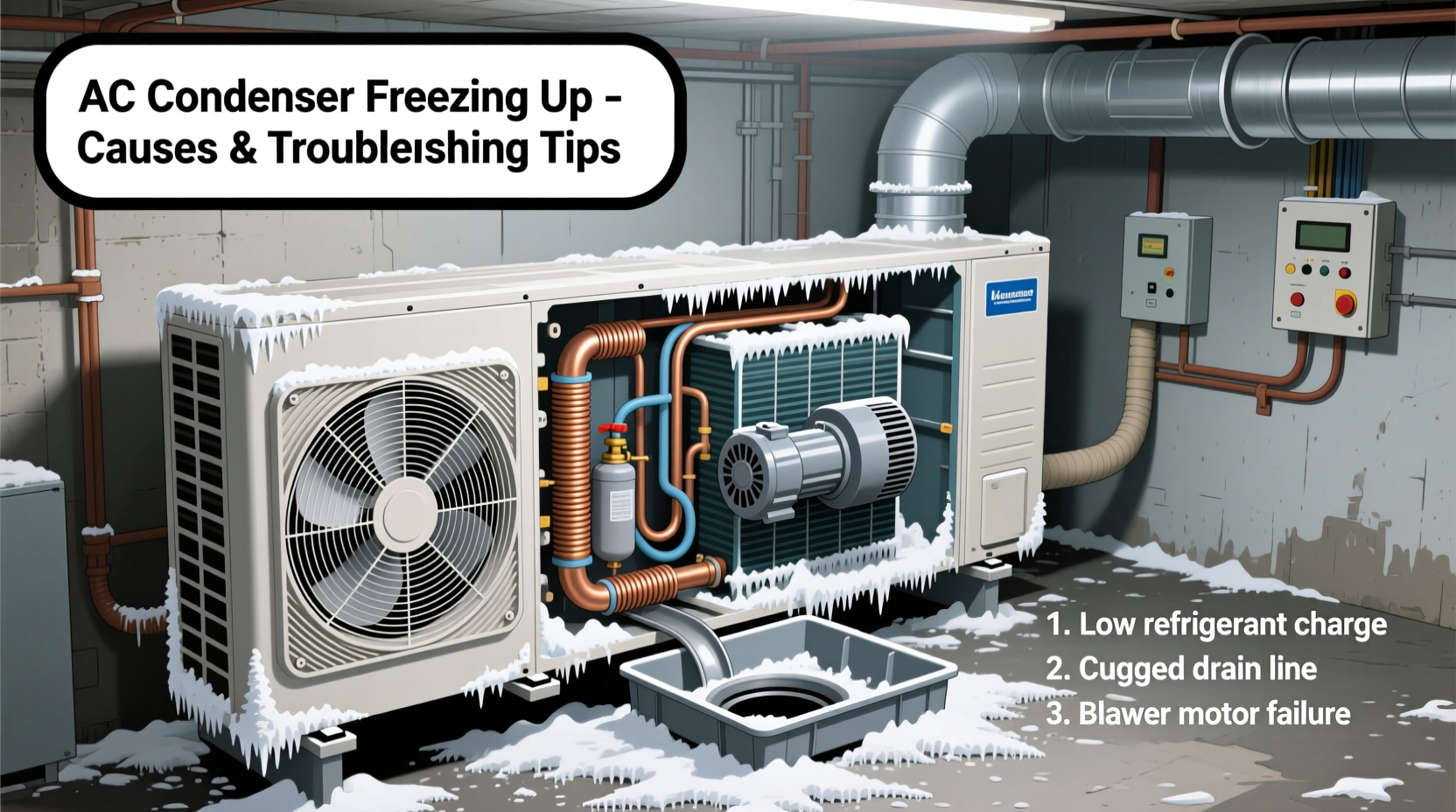

An air conditioning system is essential for comfort during hot weather, but when the outdoor condenser unit starts forming ice, it’s a sign something is seriously wrong. A frozen condenser doesn’t just reduce cooling efficiency—it can lead to costly repairs if ignored. Understanding the root causes and knowing how to respond quickly can save time, money, and discomfort.

Condenser freezing typically results from restricted airflow, low refrigerant levels, or mechanical failure. While some issues require professional help, many homeowners can identify early warning signs and take preventive action before major damage occurs.

Common Causes of a Frozen AC Condenser

The condenser coil in your outdoor unit is designed to release heat absorbed from indoors. When conditions disrupt this process, moisture in the surrounding air freezes on the cold coil. Several interrelated factors contribute to this problem:

- Low refrigerant charge: Refrigerant absorbs heat from indoor air. If levels are too low—due to leaks or improper charging—the pressure drops, causing the evaporator coil to become excessively cold. This sub-zero temperature causes condensation to freeze.

- Clogged air filter: A dirty air filter restricts airflow over the evaporator coil. Without sufficient warm air passing through, the coil temperature plummets, leading to ice buildup that can spread to the condenser line.

- Failing blower motor: The indoor blower circulates air across the evaporator coil. If it runs slowly or stops intermittently, airflow drops dramatically, increasing freeze risk.

- Obstructed return vents: Furniture, rugs, or closed doors blocking return air pathways reduce system airflow, mimicking the effect of a clogged filter.

- Outdoor unit blockage: Overgrown foliage, debris, or poor clearance around the condenser prevents proper heat dissipation and can indirectly affect internal pressures.

- Thermostat or control board issues: A malfunctioning thermostat may cause the system to run continuously, especially in mild temperatures, promoting coil icing over time.

Troubleshooting Steps to Diagnose and Fix a Frozen Unit

If you notice frost or ice on copper lines or the condenser cabinet, shut off the cooling function immediately—but keep the fan running. This allows the ice to thaw gradually without damaging components.

- Turn off the AC at the thermostat. Set the fan to “ON” to help melt existing ice using ambient air.

- Inspect the air filter. Replace if dirty. Even a slightly clogged filter can trigger freezing under high-load conditions.

- Check all supply and return vents. Ensure they’re fully open and unobstructed by furniture or drapes.

- Examine the indoor blower compartment. Listen for unusual noises or weak airflow. If the blower isn’t spinning properly, it may need cleaning or motor replacement.

- Look at refrigerant lines. Ice extending from the indoor unit to the outdoor condenser suggests an evaporator coil freeze due to airflow or refrigerant issues.

- Clear debris around the outdoor unit. Remove leaves, grass clippings, or shrubs within 2 feet of the condenser for optimal airflow.

- Wait 1–3 hours for full defrosting. Do not chip ice off coils—this can damage fins or tubing.

- Restart the system cautiously. Monitor airflow and listen for normal operation. If ice returns within hours, stop use and call a technician.

Do’s and Don’ts When Dealing With a Frozen Condenser

| Action | Recommended? | Reason |

|---|---|---|

| Run the fan to thaw ice | ✅ Yes | Promotes safe, even melting without component stress |

| Replace a dirty air filter | ✅ Yes | Restores airflow and prevents recurrence |

| Use a hairdryer to speed thawing | ❌ No | Uneven heat can warp coils or damage insulation |

| Tap or scrape off ice | ❌ No | Risks puncturing thin copper lines or bending fins |

| Check thermostat settings | ✅ Yes | Ensures correct mode and cycle timing |

| Add refrigerant yourself | ❌ No | Illegal without EPA certification; masks leaks instead of fixing them |

When to Call a Professional Technician

Some problems go beyond DIY fixes. Refrigerant leaks, compressor faults, or electrical control failures require specialized tools and expertise. Ignoring these issues leads to higher energy bills, inconsistent cooling, and eventual system failure.

“Over 60% of condenser freeze-ups we diagnose stem from long-term neglect of basic maintenance like filter changes and coil cleaning.” — Marcus Tran, HVAC Lead Technician, Metro Climate Services

A qualified technician will:

- Measure superheat and subcooling to verify refrigerant charge accuracy

- Inspect for leaks using electronic detectors or dye

- Clean evaporator and condenser coils thoroughly

- Test capacitor function and motor amperage draw

- Verify thermostat calibration and wiring integrity

Real-World Example: Homeowner Prevents Costly Repair

Sarah L., a homeowner in Austin, noticed her second-floor rooms weren’t cooling properly. She went outside and saw frost forming on the refrigerant line near the condenser. Instead of cranking down the thermostat, she turned off cooling and set the fan to “On.”

After replacing a heavily clogged filter and clearing blocked return vents behind a bookshelf, she waited two hours for complete thawing. When she restarted the system, airflow improved significantly, and no ice returned. A technician later confirmed slightly low refrigerant but credited Sarah’s quick response with preventing compressor strain and further damage.

This case illustrates how simple awareness and prompt action can avoid thousands in repair costs.

Preventive Maintenance Checklist

To keep your AC running efficiently and avoid future freezing, follow this seasonal checklist:

- ☑ Replace or clean air filter monthly during heavy use

- ☑ Vacuum return grilles and ensure unrestricted airflow

- ☑ Trim vegetation at least 18 inches away from outdoor unit

- ☑ Inspect thermostat performance and battery life

- ☑ Listen for abnormal sounds (grinding, clicking, squealing)

- ☑ Schedule professional tune-up every 12 months

- ☑ Monitor cooling consistency room-to-room

Frequently Asked Questions

Can low outdoor temperatures cause my AC condenser to freeze?

Yes. Running your AC when outdoor temps drop below 60°F (15°C) can cause freezing because there isn’t enough ambient heat for proper refrigerant evaporation. Most systems aren’t designed to operate efficiently in cool weather.

How long does it take for a frozen AC to thaw?

Depending on the extent of ice buildup, full defrosting can take 1 to 3 hours. Larger units or severe blockages may require longer. Patience is key—rushing the process risks equipment damage.

Is a frozen condenser dangerous?

It won’t explode, but continued operation can overwork the compressor, leading to premature failure. Moisture from melted ice can also drip into electrical components if drainage paths are blocked, creating safety hazards.

Take Action Before Summer Hits

A frozen AC condenser is more than an inconvenience—it’s a warning sign. By understanding the underlying causes and taking proactive steps, you protect both your comfort and your investment. Regular maintenance, timely filter changes, and early detection make all the difference.

Don’t wait until the hottest day of the year to discover a problem. Review your system today, clear obstructions, and schedule a professional inspection if you’ve had recurring issues. Your future self—and your wallet—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?