When it comes to clothing construction, few details seem as small yet essential as buttons. Found on everything from shirts and coats to jeans and blazers, buttons are both functional and aesthetic. But when durability is a priority—especially in workwear, outerwear, or frequently worn garments—the question arises: Are metal buttons truly more durable than fabric-covered ones? And if one fails before the other, what exactly breaks first? The answer isn’t as straightforward as material alone might suggest.

Durability depends not just on the button’s composition but also on stress distribution, sewing technique, garment use, and environmental exposure. To understand which lasts longer and why, we need to examine how each type performs under real-world conditions.

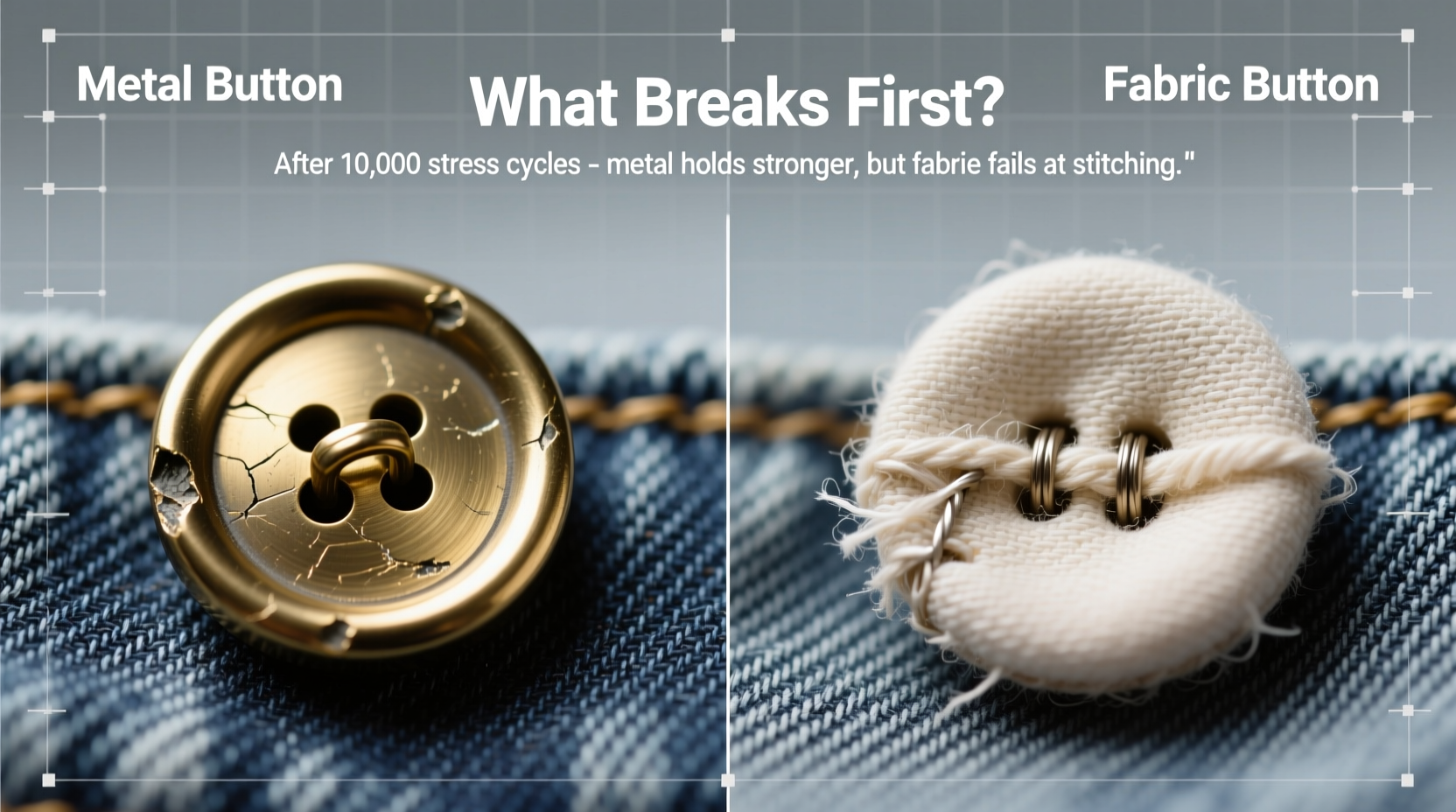

The Anatomy of Button Failure

Before comparing metal and fabric buttons, it's important to clarify what \"breaks first\" really means. A button can fail in several ways:

- Shank or stem fracture: The part attaching the button to the fabric snaps.

- Thread detachment: The stitching holding the button unravels or cuts through the fabric.

- Surface degradation: Corrosion, chipping, or unraveling of decorative layers.

- Buttonhole stress: The surrounding fabric wears out before the button itself fails.

In most cases, the button doesn't \"break\"—it detaches. This shifts focus from the button material to the quality of attachment and the strength of the fabric around it.

Metal Buttons: Strength with Trade-offs

Metal buttons, typically made from alloys like brass, nickel, or steel, are renowned for their rigidity and resistance to deformation. They’re commonly used in military uniforms, denim, and heavy-duty jackets because they withstand repeated fastening and resist crushing.

However, metal has inherent weaknesses:

- Corrosion risk: Exposure to moisture, sweat, or salt can cause oxidation, especially in low-grade metals.

- Rigidity leads to stress concentration: When a garment flexes, metal buttons don’t bend, increasing strain on threads and fabric.

- Noise and cold conduction: Practical concerns, though not related to durability.

“Metal buttons outlast fabric ones in abrasion tests, but they often fail due to poor shank design or inadequate thread anchoring.” — Dr. Lena Torres, Textile Engineer, MIT Materials Lab

Fabric-Covered Buttons: Elegance Meets Vulnerability

Fabric-covered buttons are typically constructed with a plastic or metal core wrapped in matching garment fabric. They offer seamless aesthetics and are common in tailored clothing like dress shirts, suits, and blouses.

Their advantages include:

- Visual integration: Blend perfectly with the garment.

- Flexibility: Slight give reduces stress on stitching points.

- Lightweight: Less strain on thin fabrics.

But their vulnerabilities are significant:

- Fabric wear: The covering can fray, stain, or detach over time.

- Core exposure: Once the fabric wears off, the underlying core may look unsightly or weaken.

- Water damage: Moisture can warp cores or cause mold under the fabric layer.

What Breaks First? Real-World Wear Scenarios

To determine actual failure rates, consider different usage environments:

Casual Shirts (Cotton or Linen)

Fabric-covered buttons are common here for appearance. However, frequent washing and friction from belts or seatbacks often lead to thread loosening. The fabric cover may discolor or fray, but rarely does the core break. Instead, the button pulls off due to thread fatigue.

Denim Jackets and Workwear

Metal buttons dominate this category. While the metal rarely cracks, repeated flexing at the waist or cuff causes the thread to saw through the denim. In many vintage denim pieces, original metal buttons remain intact—but reattached multiple times due to thread failure.

Tailored Coats and Blazers

High-end wool coats often use fabric-covered buttons for elegance. Over years of seasonal use, these buttons endure less mechanical stress but face moth damage, dry rot, or accidental snagging. The fabric layer is usually the first to degrade, making the button look worn even if structurally sound.

Comparative Durability: Metal vs. Fabric Buttons

| Criteria | Metal Buttons | Fabric-Covered Buttons |

|---|---|---|

| Tensile Strength | High – resists pulling force | Medium – limited by thread and fabric integrity |

| Abrasion Resistance | Excellent – surface hardens over time | Poor – fabric layer wears quickly |

| Corrosion/Moisture Resistance | Varies – depends on plating and alloy | Fair – fabric absorbs moisture; core may degrade |

| Aesthetic Longevity | Fair – may tarnish or scratch | Good initially, declines with fabric wear |

| Attachment Reliability | High if properly stitched | Lower – fabric stretch increases thread stress |

| Repairability | Easy to reattach | Harder – replacement must match fabric |

The table shows that while metal buttons win in mechanical strength, neither type is immune to failure—just vulnerable in different ways.

Expert Installation Matters More Than Material

The biggest factor in button longevity isn’t the button itself, but how it’s attached. A poorly sewn metal button will fail faster than a well-mounted fabric one.

Key installation practices include:

- Using strong, waxed thread (e.g., polyester or nylon).

- Creating a thread shank on 2-hole or 4-hole buttons to allow fabric movement.

- Securing knots with backstitches or fabric backing.

- Reinforcing high-stress areas (like coat fronts) with interfacing.

“The strongest button is only as good as its weakest stitch. I’ve seen brass buttons last 20 years on a coat because they were set with a double-thread shank.” — Rafael Mendez, Master Tailor, Barcelona Atelier

Mini Case Study: The 15-Year Denim Jacket

Consider a pair of raw denim jeans owned by a field photographer who wore them daily for over a decade. The jeans were washed sparingly, but subjected to constant movement, kneeling, and exposure to dust and rain.

After 15 years, all five metal rivet-style buttons remained intact. However, two had been resewn twice due to thread fraying. The buttonholes showed more wear than the buttons themselves—particularly at the top, where tension was highest. No button cracked, corroded, or deformed.

In contrast, a fabric-covered button on his wool peacoat, worn seasonally, began showing fraying after six years. The thread held, but the fabric wrap lifted at one edge, exposing the plastic core. Aesthetically, it looked broken—even though functionally it wasn’t.

This illustrates a key insight: functional durability and visual durability are not the same.

Checklist: Maximizing Button Longevity

Whether you choose metal or fabric buttons, follow these steps to extend their life:

- ✔ Use high-strength thread appropriate for the fabric weight.

- ✔ Create a small thread shank on non-flat buttons to reduce stress.

- ✔ Reinforce button areas with interfacing, especially on heavy garments.

- ✔ Avoid over-tightening buttons, which strains both button and buttonhole.

- ✔ Inspect buttons quarterly for loose threads or signs of wear.

- ✔ Replace weak or damaged buttons proactively, not reactively.

- ✔ Store garments unbuttoned to relieve long-term tension.

Frequently Asked Questions

Do metal buttons rust?

Yes, especially if made from iron-based alloys or poorly plated. Brass and anodized aluminum resist corrosion better. Sweat and humidity accelerate rusting, so consider coated or marine-grade metals for activewear.

Can fabric-covered buttons be repaired?

Sometimes. If the core is intact and the fabric hasn’t rotted, a tailor can re-cover the button using leftover garment fabric. However, color matching over time can be difficult, and it’s often more practical to replace the entire button.

Which button type is best for children’s clothing?

Fabric-covered or molded plastic buttons are safer and softer, reducing skin irritation and injury risk. Durability is secondary to safety here, though reinforced stitching is still essential due to rough handling.

Conclusion: It’s Not the Button, It’s How It’s Used

Metal buttons are generally more durable under mechanical stress, but they aren’t invincible. Fabric-covered buttons offer elegance and flexibility but degrade faster in appearance. In most cases, neither fails catastrophically—instead, the connection between button and fabric gives way first.

The real determinant of longevity is craftsmanship: the quality of thread, the precision of stitching, and the design of stress distribution. A well-made garment with either button type can last decades. Conversely, even the strongest metal button will fail prematurely if improperly installed.

Next time you notice a missing button, don’t blame the material—check the stitches. And when choosing or repairing garments, prioritize secure attachment over superficial toughness.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?