Minerals are essential to modern life. From the smartphones in our pockets to the cars we drive and the buildings we inhabit, nearly every aspect of contemporary society depends on mineral resources. Yet few people understand whether these materials are renewable or non-renewable — a distinction with profound implications for environmental sustainability, economic planning, and global equity. This article explores the nature of mineral resources, explains why most are classified as non-renewable, and discusses what that means for current and future generations.

What Are Minerals?

Minerals are naturally occurring inorganic solids with a definite chemical composition and crystalline structure. They form through geological processes such as cooling magma, precipitation from solutions, or metamorphism under heat and pressure. Common examples include iron, copper, gold, lithium, quartz, and feldspar.

These substances are extracted from the Earth’s crust through mining and processed for use in construction, electronics, energy production, and manufacturing. While some minerals are abundant, others exist in limited quantities and are concentrated in specific regions of the world.

Renewable vs. Non-Renewable Resources: A Fundamental Distinction

To determine whether minerals are renewable, it's crucial to define the terms:

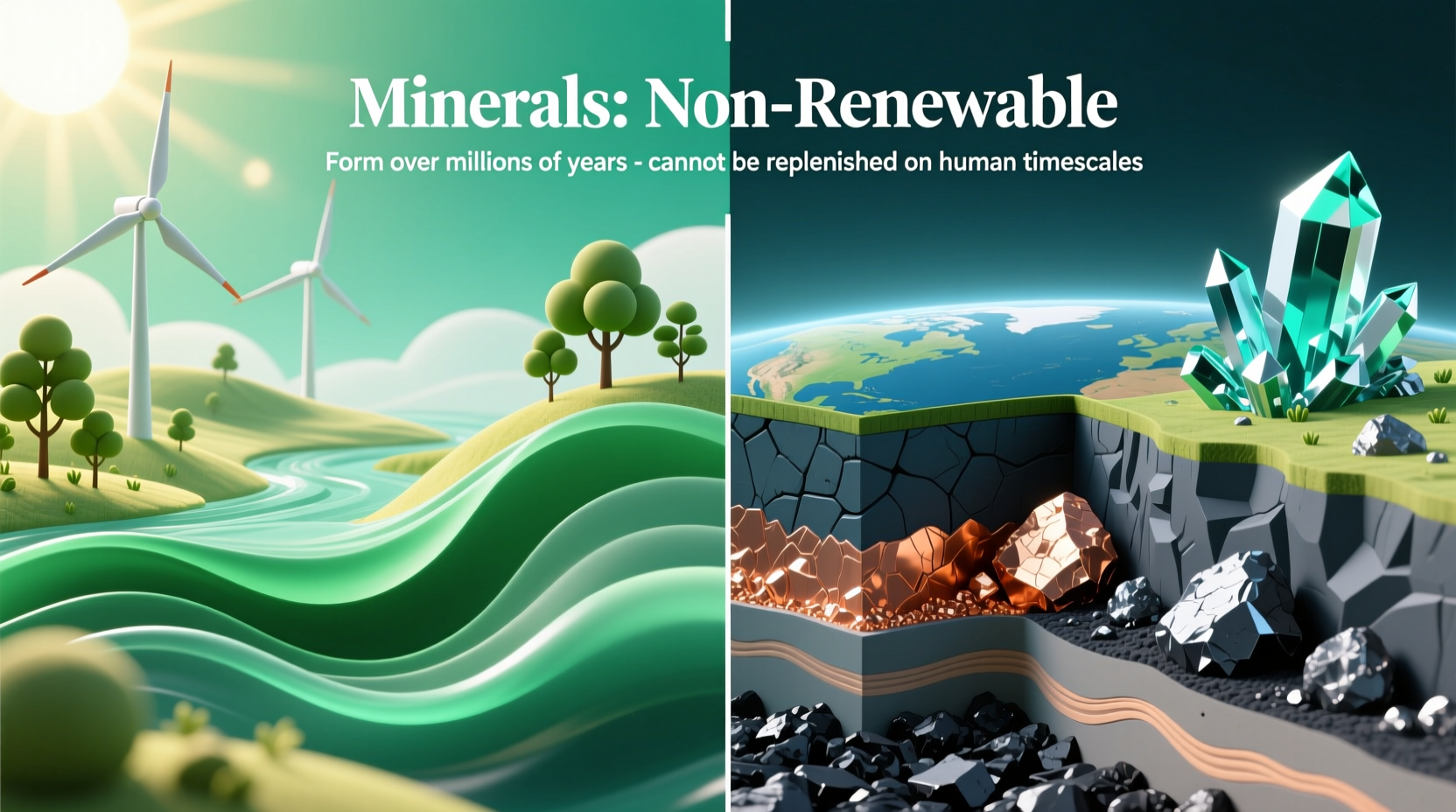

- Renewable resources are those that can be replenished naturally within a human timescale — typically within decades or centuries. Examples include solar energy, wind power, timber (when sustainably harvested), and agricultural crops.

- Non-renewable resources are finite; once depleted, they cannot be replaced within any meaningful timeframe. These include fossil fuels like coal and oil, as well as most metallic and non-metallic minerals.

The key factor is the rate of regeneration. While the Earth continues to form new minerals through tectonic and volcanic activity, this process takes millions of years — far longer than the pace at which humans extract and consume them.

“From a human perspective, minerals are effectively non-renewable because their formation spans geological epochs, not human lifetimes.” — Dr. Lena Patel, Geoscientist and Resource Sustainability Researcher

Why Most Minerals Are Considered Non-Renewable

Despite being part of natural Earth cycles, minerals fail the renewability test due to three main reasons:

- Extremely slow formation rates: The creation of economically viable mineral deposits requires specific conditions — high pressure, temperature, and time — that occur over tens of millions of years. For example, copper porphyry deposits take 10–100 million years to form.

- Irreversible extraction: Once mined and dispersed into products and waste streams, minerals are rarely recovered in pure form. Recycling helps, but recovery rates vary widely by material and region.

- Finite concentration: High-grade ore bodies are limited. As demand increases, mining operations turn to lower-grade sources, requiring more energy and generating more waste.

Exceptions and Gray Areas

A few mineral-like resources blur the line between renewable and non-renewable:

- Salt (halite): Extracted from seawater or underground deposits, salt is technically renewable through evaporation cycles, though industrial-scale harvesting treats it as finite.

- Silica sand: Abundant and constantly replenished by weathering, but high-purity quartz used in semiconductors is limited.

- Recycled metals: While not naturally renewed, metals like aluminum and copper can be recycled indefinitely without losing quality, giving them near-renewable characteristics if systems are efficient.

Global Mineral Use and Depletion Trends

Modern civilization consumes minerals at an unprecedented rate. According to the U.S. Geological Survey, global mine production of copper has increased tenfold since 1950, while lithium output has surged over 300% in the past decade alone due to battery demand.

This rapid consumption raises concerns about peak availability. Some experts warn of potential shortages in critical minerals such as cobalt, rare earth elements, and indium — all vital for green technologies like electric vehicles and solar panels.

| Mineral | Primary Uses | Estimated Remaining Reserve Life* |

|---|---|---|

| Copper | Electrical wiring, plumbing, electronics | ~40 years at current usage |

| Lithium | Batteries, pharmaceuticals | ~17 years (economically viable reserves) |

| Phosphorus | Fertilizers, food production | ~50–100 years |

| Rare Earth Elements | Magnets, lasers, defense tech | Highly variable; some under 20 years |

*Estimates based on USGS data and current global extraction rates; recycling could extend these timelines.

Case Study: The Lithium Boom in South America

In Chile’s Atacama Desert, one of the world’s largest lithium reserves lies beneath salt flats known as salars. Over the past two decades, international companies have expanded brine extraction operations to meet rising demand for rechargeable batteries.

While lithium is relatively abundant, its extraction requires vast amounts of water in one of the driest regions on Earth. Local communities report declining groundwater levels and damaged ecosystems. Moreover, once processed and exported, very little lithium is recovered — less than 5% is currently recycled globally.

This case illustrates how even a single mineral’s lifecycle — from extraction to disposal — reflects broader issues of resource finiteness, environmental impact, and social justice. Though new sources are being explored, including geothermal brines and seawater extraction, none offer scalable, low-impact alternatives yet.

Strategies for Sustainable Mineral Management

Given the non-renewable nature of most minerals, long-term sustainability depends on proactive strategies. Here’s a checklist individuals, industries, and governments can follow:

- Improve urban mining and e-waste recycling infrastructure

- Design products for disassembly and material recovery

- Invest in research for alternative materials and substitution

- Support policies that promote circular economy models

- Encourage responsible sourcing and transparency in supply chains

- Reduce personal consumption of high-mineral-intensity devices

Step-by-Step Guide to Responsible Consumer Choices

- Evaluate need: Before purchasing electronics or appliances, ask whether an upgrade is truly necessary.

- Choose durability: Opt for high-quality, repairable products with modular designs.

- Check certifications: Look for labels like Fairphone, EPEAT, or TCO Certified that prioritize ethical sourcing.

- Recycle properly: Return old devices to certified e-waste recyclers instead of discarding them.

- Advocate: Support legislation that mandates producer responsibility and improves recycling rates.

Frequently Asked Questions

Can minerals ever be considered renewable?

Only in theoretical or highly specific contexts. For practical purposes, especially in economic and policy discussions, minerals are treated as non-renewable due to their extremely slow natural regeneration rates.

Is recycling enough to make minerals sustainable?

Recycling significantly extends the usability of minerals, particularly metals like steel, aluminum, and copper. However, current global recycling rates are inadequate, and losses occur during processing. Recycling alone cannot replace the need for reduced consumption and better design.

What happens when we run out of key minerals?

We may never \"run out\" entirely, but accessing remaining reserves will become increasingly expensive and environmentally damaging. Scarcity could lead to price spikes, geopolitical tensions, and disruptions in technology and infrastructure unless alternatives are developed.

Conclusion: Rethinking Our Relationship with Earth’s Hidden Wealth

Minerals are the invisible backbone of modern civilization. Recognizing them as largely non-renewable forces us to confront uncomfortable truths about consumption, waste, and intergenerational responsibility. Unlike renewable energy sources, there is no infinite supply of copper, cobalt, or rare earths waiting to be tapped.

The solution isn’t to halt progress, but to redefine it. By embracing circular economies, advancing recycling technologies, and designing smarter products, we can reduce our dependence on virgin mineral extraction. Every device repaired, every component reused, and every policy enacted to support sustainability brings us closer to a future where mineral wealth serves humanity without depleting the planet.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?