When selecting a filament for outdoor or high-stress applications, two materials often rise to the top: ASA and PETG. Both are tough, durable thermoplastics with excellent mechanical properties, but they differ significantly in performance, print requirements, and price. ASA typically costs 20–40% more than PETG, raising a practical question for hobbyists and professionals alike: Is the premium justified? The answer depends on your project’s demands—especially regarding UV resistance, long-term stability, and environmental exposure.

Mechanical Properties and Durability Compared

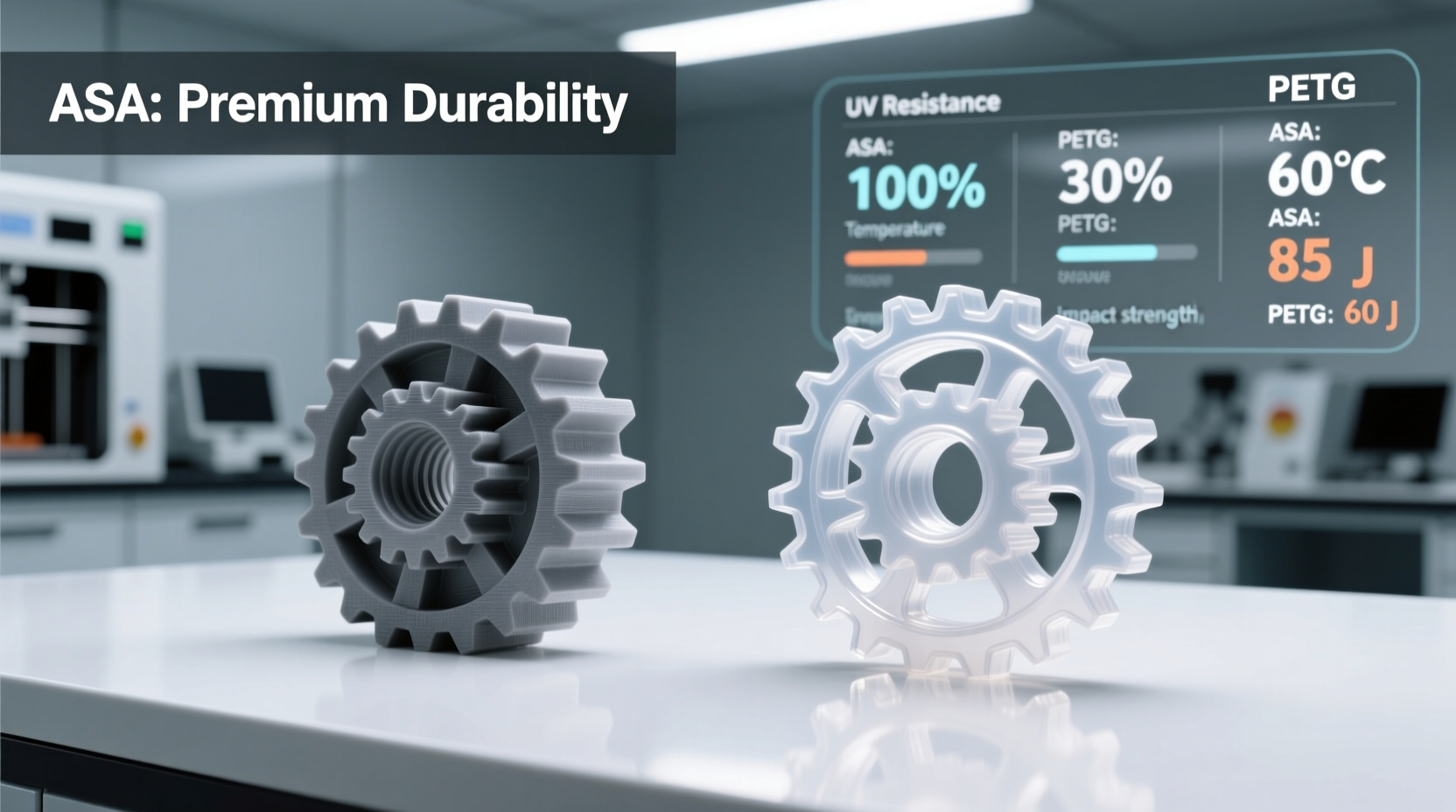

Both ASA (Acrylonitrile Styrene Acrylate) and PETG (Polyethylene Terephthalate Glycol) offer strong impact resistance and good tensile strength, making them suitable for functional parts. However, their behavior under stress and over time diverges.

ASA has a tensile strength of approximately 40–50 MPa and exhibits superior toughness in cold temperatures. It maintains dimensional stability better than PETG when exposed to prolonged heat or sunlight. Its glass transition temperature sits around 100°C, allowing it to resist deformation in moderately hot environments.

PETG, while slightly stronger in raw tensile tests (around 50 MPa), is more prone to creep under sustained load. It softens at lower temperatures (~80°C) and can deform in direct sunlight over time, especially in dark-colored prints that absorb heat. While it’s highly impact-resistant, its long-term structural integrity outdoors is limited without protective coatings.

UV and Weather Resistance: Where ASA Shines

This is the most critical differentiator. ASA was developed specifically as a UV-stable alternative to ABS, making it one of the few filaments that can endure prolonged sun exposure without significant degradation. It resists fading, chalking, and embrittlement far better than almost any other common 3D printing plastic.

In contrast, PETG may appear stable initially but begins to yellow and lose impact strength after just a few months in direct sunlight. A study by Formlabs found that untreated PETG samples lost up to 30% of their impact resistance after 500 hours of accelerated UV exposure, while ASA retained over 90%.

“ASA is the go-to material for outdoor automotive trim and signage in industrial manufacturing. Its weatherability isn’t incidental—it’s engineered.” — Dr. Lena Torres, Materials Scientist at ProtoBuild Labs

If your part will be mounted on a drone, used in garden equipment, or installed on a rooftop enclosure, ASA’s longevity can reduce replacement frequency and maintenance costs over time—offsetting its higher initial price.

Printability and Equipment Requirements

PETG is widely praised for being user-friendly. It prints at moderate temperatures (230–250°C), adheres well to standard build surfaces, and doesn’t require an enclosed printer. Warping is minimal, and layer adhesion is strong even without heated chambers.

ASA, however, behaves more like ABS. It requires a heated bed (90–110°C), an enclosed print chamber to maintain consistent ambient temperature, and often a glue stick or specialized adhesive for reliable first-layer adhesion. Without proper conditions, corner lifting and delamination are common.

Moreover, ASA emits stronger fumes during printing, particularly styrene compounds, which demand active ventilation or filtration. This adds operational complexity and potentially additional hardware costs if you're upgrading from a basic setup.

| Factor | PETG | ASA |

|---|---|---|

| Printing Temp | 230–250°C | 240–260°C |

| Bed Temp | 60–80°C | 90–110°C |

| Enclosure Needed? | No | Yes |

| Warping Risk | Low | High |

| Ventilation Required? | Moderate | Strongly Recommended |

Real-World Application: A Case Study

A small engineering firm in Arizona specializes in custom drone-mounted sensors for agricultural monitoring. They initially used PETG for all external housings due to its ease of printing and low cost. After six months in field use, however, several units showed severe yellowing, surface cracking, and joint failures after repeated thermal cycling.

The team switched to ASA for new builds. Despite a 35% increase in material cost and the need to retrofit their printers with enclosures and carbon filters, the failure rate dropped to zero over the next 18 months. Maintenance visits decreased, customer satisfaction improved, and warranty claims were eliminated.

“We spent $200 upgrading two printers,” said lead engineer Marcus Lin, “but saved over $2,000 in service calls and replacements in the first year alone. ASA paid for itself three times over.”

Cost-Benefit Analysis Over Time

While ASA costs more per spool—often $28–$35 compared to PETG’s $20–$28—the true cost includes labor, replacement frequency, and downtime. Consider this breakdown for a production run of 50 outdoor sensor enclosures:

- PETG Option: Lower material cost ($1,200 total), but 30% failure rate within one year → 15 replacements needed → additional printing, shipping, and labor costs (~$600).

- ASA Option: Higher material cost ($1,600 total), near-zero failure rate → no replacements → net savings of $200 despite higher initial spend.

Additionally, ASA parts retained their appearance and functionality, enhancing brand perception. For commercial applications, reliability often outweighs short-term savings.

Step-by-Step Guide to Choosing Between ASA and PETG

- Define the environment: Will the part be outdoors, in direct sunlight, or exposed to heat above 70°C?

- Evaluate lifespan needs: Is this a disposable prototype or a component expected to last years?

- Assess printer capabilities: Do you have an enclosed printer with ventilation and a reliable heated bed?

- Calculate total cost: Factor in potential replacements, labor, and downtime—not just filament price.

- Test a sample: Print identical test bars in both materials and expose them to real-world conditions for 4–6 weeks.

Frequently Asked Questions

Can I paint or post-process ASA and PETG the same way?

Yes, both can be sanded, glued, and painted. However, ASA accepts ABS-based welds and acetone smoothing better than PETG, which responds poorly to strong solvents. For painting, use primers designed for plastics and always test adhesion first.

Is there a UV-resistant PETG available?

Some manufacturers offer \"UV-stabilized\" PETG, but independent tests show these variants still degrade faster than standard ASA. They may extend life by a few months, but not match ASA’s multi-year stability.

Does ASA require drying before printing?

Absolutely. Like PETG, ASA is hygroscopic. Always dry ASA at 65–70°C for 4–6 hours before printing to prevent bubbling, poor layer adhesion, and weakened parts.

Final Verdict: When the Extra Cost Makes Sense

The added expense of ASA is absolutely worth it—if your application demands long-term outdoor durability, thermal stability, and structural reliability. For indoor prototypes, mechanical testing, or short-term fixtures, PETG remains the smarter, more economical choice.

The decision isn’t about which material is “better” overall, but which aligns with your project’s lifecycle requirements. Investing in ASA means investing in longevity, reduced maintenance, and professional-grade results. If your prints will face the elements, that premium isn’t just justified—it’s essential.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?