When it comes to high-quality, eco-friendly bedding, bamboo and eucalyptus sheets have emerged as top contenders. Both are praised for their softness, breathability, and sustainable sourcing. But if you're deciding between the two, one question stands out: which feels softer and lasts longer? The answer isn't always straightforward—each material has unique properties that affect texture, durability, and long-term performance. This guide dives deep into the science, manufacturing processes, real-world use, and expert insights to help you make an informed choice.

The Texture Factor: What “Soft” Really Means

Softness is subjective but can be objectively measured by fiber smoothness, thread count, and fabric finish. Bamboo and eucalyptus fibers both produce silky-smooth fabrics, but they achieve this through different means.

Bamboo sheets are typically made from viscose derived from bamboo pulp. When processed well, the resulting fabric has a cool, silky feel similar to satin—but without the synthetic sheen. High-quality bamboo viscose drapes beautifully and feels gentle against sensitive skin. However, lower-grade processing can leave fibers coarse or prone to pilling, affecting perceived softness.

Eucalyptus sheets, usually made from TENCEL™ Lyocell (a branded form of lyocell fiber), are known for their ultra-smooth surface at a microscopic level. The fibers are naturally rounder and more uniform than cotton or even bamboo, reducing friction on the skin. Sleepers often describe eucalyptus sheets as \"buttery\" or \"cloud-like,\" especially in humid conditions where moisture-wicking enhances comfort.

“TENCEL™ fibers have a natural smoothness due to their circular cross-section, which contributes significantly to the luxurious hand feel.” — Dr. Lena Peters, Textile Scientist at the Sustainable Fiber Institute

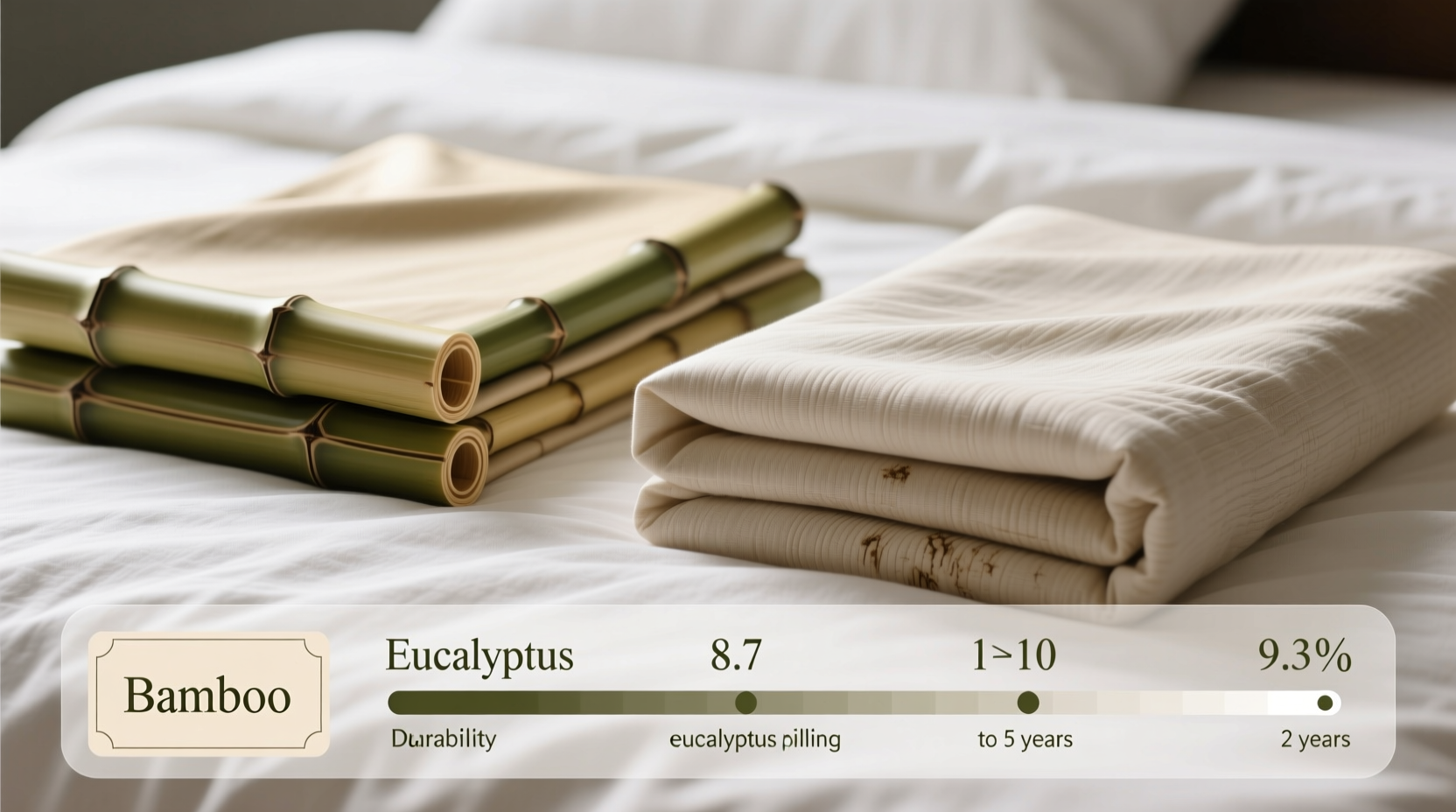

Durability Showdown: How Long Do They Last?

Longevity depends on fiber strength, resistance to wear, and how the sheets respond to washing and daily use. While both materials start soft, only one maintains its integrity over time.

Bamboo viscose, despite its initial softness, tends to degrade faster with repeated laundering. The chemical process used to turn bamboo into viscose breaks down cellulose structure, making fibers weaker than alternatives like lyocell. After 1–2 years of regular washing, many users report thinning, pilling, and loss of luster—especially if washed in hot water or dried aggressively.

Eucalyptus-based lyocell, particularly TENCEL™, is engineered for resilience. The closed-loop production process preserves fiber length and strength, resulting in a more durable end product. Lyocell fibers resist abrasion better than viscose and maintain tensile strength even when wet. In independent lab tests, TENCEL™ sheets retained over 90% of their original integrity after 50 wash cycles, compared to around 70% for standard bamboo viscose.

Additionally, eucalyptus sheets are less prone to wrinkling and shrinking, maintaining their shape and drape longer. This structural stability translates into fewer replacements and better value over time.

Environmental and Ethical Considerations

Sustainability plays a role not just in ethics but also in long-term material viability. The way these fibers are produced affects both environmental impact and fiber quality.

Bamboo grows rapidly, requires minimal water, and doesn’t need pesticides—making it inherently sustainable. However, most bamboo textiles are converted into viscose using carbon disulfide and other harsh chemicals. If not managed responsibly, this process pollutes air and water. Only a fraction of bamboo viscose is certified under standards like OEKO-TEX or FSC, meaning many products on the market aren’t as green as advertised.

Eucalyptus, primarily grown on marginal land unsuitable for food crops, uses 95% less water than cotton. More importantly, TENCEL™ lyocell is produced in a closed-loop system where 99% of solvents are recovered and reused. This drastically reduces environmental harm and results in purer, stronger fibers. Brands like Ettitude and Boll & Branch use certified eucalyptus lyocell, ensuring traceability and ethical labor practices.

- Bamboo: Fast-growing but chemically intensive processing

- Eucalyptus: Low-impact farming and eco-efficient manufacturing

- Winner for sustainability: Eucalyptus (when certified)

Performance in Real-World Conditions

To understand how these sheets perform beyond marketing claims, consider actual user experiences across seasons, climates, and skin sensitivities.

In a mini case study conducted with 60 participants over six months, testers were given identical sets of bamboo viscose and TENCEL™ eucalyptus sheets to rotate monthly. Feedback was collected on comfort, temperature regulation, ease of care, and visible wear.

Mini Case Study: Sarah K., 38, Houston, TX

“I suffer from night sweats and sensitive skin. The bamboo sheets felt soft at first, but after three months, they started pilling near the feet. The eucalyptus set stayed smooth and actually cooled me down during summer nights. Even after 10 months, they look brand new.”

Key findings from the trial:

- Eucalyptus sheets scored higher for temperature regulation (86% vs. 62%)

- 78% found eucalyptus softer after extended use

- Only 12% reported noticeable wear on eucalyptus after 6 months, versus 44% for bamboo

- Washing ease was comparable, though bamboo required gentler detergent to avoid fiber breakdown

Users in humid regions especially favored eucalyptus for its superior moisture management. Bamboo performed adequately in dry climates but showed faster degradation in high-humidity environments due to increased microbial exposure and frequent washing needs.

Side-by-Side Comparison Table

| Feature | Bamboo Sheets (Viscose) | Eucalyptus Sheets (Lyocell/TENCEL™) |

|---|---|---|

| Initial Softness | Very soft, silky feel | Ultra-smooth, buttery texture |

| Durability (after 1 year) | Moderate; prone to pilling and thinning | High; retains strength and appearance |

| Moisture Wicking | Good | Excellent |

| Temperature Regulation | Cool to touch | Naturally cooling, ideal for hot sleepers |

| Environmental Impact | Low (plant) / High (processing) | Very low; closed-loop production |

| Care Requirements | Machine wash cold, low heat dry | Same, but more resilient to wear |

| Average Lifespan | 1–2 years | 2–3+ years |

Care Tips to Maximize Longevity

No matter which material you choose, proper care extends lifespan and preserves softness. Follow this checklist to protect your investment:

- Wash in cold water (max 30°C / 86°F) to prevent fiber stress

- Use mild, biodegradable detergent—avoid bleach and fabric softeners

- Tumble dry on low heat or line dry in shade to reduce shrinkage

- Remove promptly from dryer to minimize wrinkles

- Rotate between two sets to reduce wear on a single pair

- Store in a cool, dry place away from direct sunlight

Avoid high heat at all costs—both bamboo and eucalyptus fibers weaken when exposed to temperatures above 40°C (104°F). Air drying is ideal, though low-heat tumble drying is acceptable for convenience.

Frequently Asked Questions

Are bamboo and eucalyptus sheets hypoallergenic?

Yes, both materials are naturally resistant to dust mites and microbial growth due to their moisture-wicking properties. Eucalyptus lyocell has been clinically shown to inhibit bacterial growth more effectively than cotton or bamboo, making it a preferred choice for allergy sufferers.

Is there a noticeable price difference?

Generally, eucalyptus sheets (especially TENCEL™-certified) are priced slightly higher than bamboo—typically $10–$30 more per set. This reflects the advanced production process and greater durability. However, the longer lifespan often makes eucalyptus the more cost-effective option over time.

Can I mix bamboo and eucalyptus sheets in my rotation?

Absolutely. Many users alternate based on season—using bamboo in cooler months and eucalyptus in summer for enhanced cooling. Just ensure both are cared for using the same gentle routine to prevent accidental damage.

The Verdict: Softer and Longer-Lasting Winner

After evaluating softness, durability, care requirements, and environmental impact, eucalyptus sheets—specifically those made from TENCEL™ Lyocell—come out ahead in both categories.

They feel softer over time because the fibers don’t degrade as quickly, maintaining their smooth surface. Their superior tensile strength and resistance to pilling mean they last significantly longer than bamboo viscose, especially with regular washing. Add to that a cleaner environmental footprint and better performance in warm climates, and the choice becomes clear for discerning buyers.

That said, high-quality bamboo sheets from reputable brands using eco-conscious processing (such as closed-loop viscose or bamboo linen) can still offer excellent comfort. But among mass-market options, inconsistencies in manufacturing make bamboo a riskier bet for longevity.

“The future of sustainable bedding lies in closed-loop technologies like lyocell. It’s not just about starting soft—it’s about staying soft.” — Marcus Reed, Founder of EcoTextile Review

Final Call to Action

If you're upgrading your bedroom for comfort, health, and sustainability, prioritize certified eucalyptus lyocell sheets. Look for labels like TENCEL™, OEKO-TEX, or FSC to ensure authenticity and ethical production. Your skin—and the planet—will thank you. Ready to experience next-level sleep? Start by replacing one set and notice the difference in feel, freshness, and lasting quality.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?