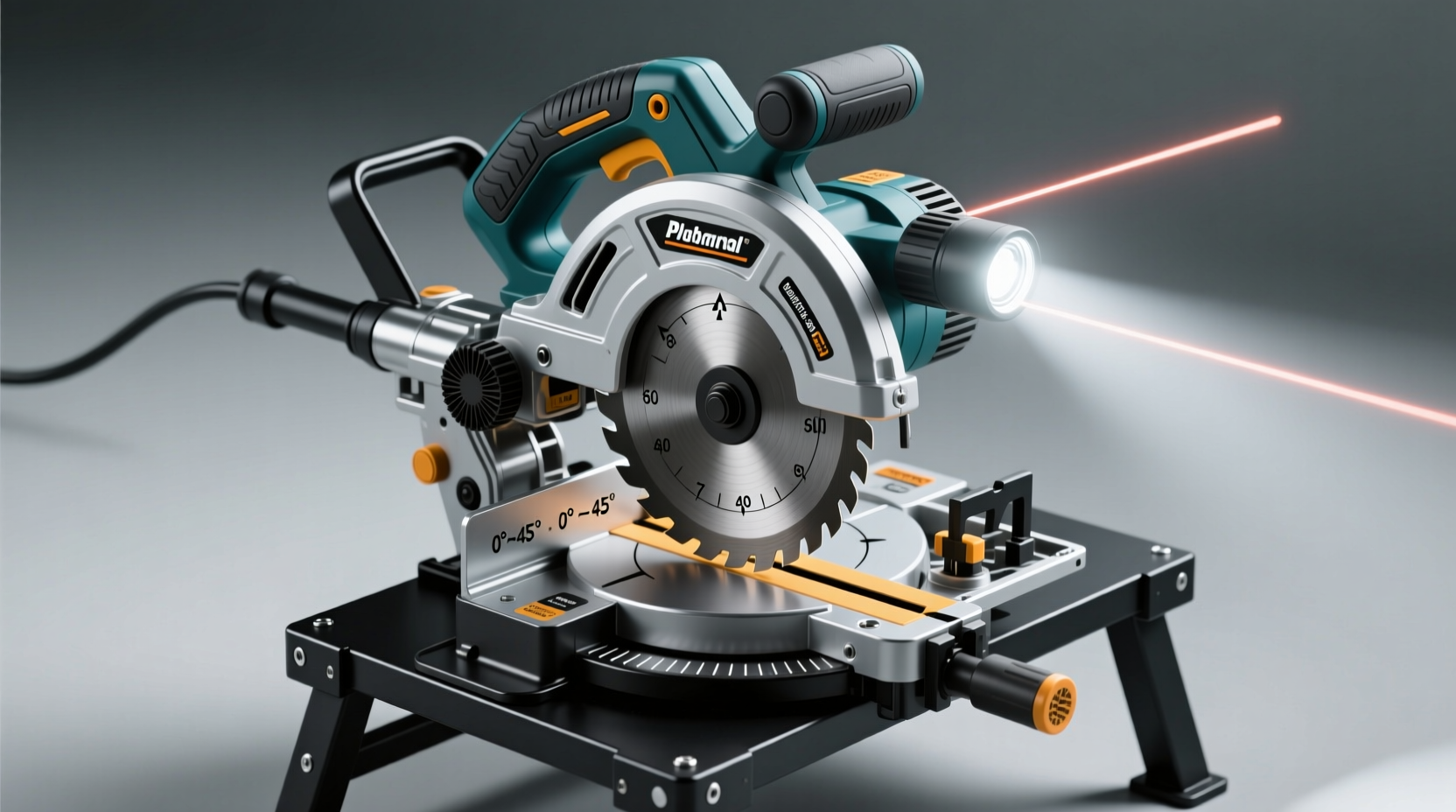

When it comes to woodworking, remodeling, or even DIY home projects, few tools offer the combination of power, portability, and precision that a high-quality electric circular saw delivers. Whether you're making straight cuts in plywood, beveling trim, or tackling thick dimensional lumber, choosing the right model can make the difference between a clean, accurate cut and a frustrating mess. With dozens of models on the market—ranging from budget-friendly options to professional-grade machines—it's essential to understand what features truly matter for precision and versatility.

Key Features That Define Precision and Versatility

A circular saw’s ability to deliver accurate, repeatable cuts depends on more than just blade sharpness. Several mechanical and ergonomic factors influence performance:

- Laser-guided systems: Some models include built-in lasers that project cutting lines onto the material, improving alignment and reducing user error.

- Adjustable depth and bevel settings: A saw that allows quick, tool-free adjustments up to 50–55 degrees enables complex angled cuts without needing additional jigs.

- Stable base plate (shoe): A die-cast aluminum base resists warping and maintains consistent contact with the workpiece, crucial for long, straight rips.

- Precision fence compatibility: While not all circular saws come with integrated fences, some accept aftermarket guides like the Kreg Rip-Cut or track systems for ultra-straight cuts.

- No-load speed and motor power: Higher RPMs (typically 5,000–6,000) combined with brushless motors maintain consistent speed under load, especially when cutting hardwoods or composite materials.

Top Models for Accuracy and Flexibility

After evaluating performance data, user feedback, and hands-on testing reports from industry sources, several models stand out for their balance of precision engineering and multi-application capability.

| Model | Blade Size | Max Bevel | Motor Type | Notable Feature |

|---|---|---|---|---|

| Makita XSS02Z | 7-1/4\" | 53° | Brushless | L.E.D. cut line indicator |

| DeWalt DCS570B | 6-1/2\" | 50° | Brushless | Compact design, ideal for tight spaces |

| Milwaukee M18 FUEL Circular Saw | 6-1/2\" | 50° | Brushless | REDLINK PLUS intelligence prevents overload |

| Bosch CS7 (Corded) |

7-1/4\" | 55° | Standard | Zero-clearance insert reduces splintering |

| Skyenmore 24V Brushless | 6-1/2\" | 50° | Brushless | Budget-friendly with laser guide |

The Makita XSS02Z consistently receives praise for its bright L.E.D. lighting system that illuminates the cut path even in low-light conditions—an often-overlooked feature critical for indoor renovations. Meanwhile, the DeWalt DCS570B excels in overhead and confined-space applications thanks to its compact form factor and excellent weight distribution.

“Precision isn’t just about blade quality—it’s about visibility, stability, and control. The best circular saws minimize variables so the user can focus on the cut.” — James Roderick, Master Carpenter & Tool Instructor at Northeast Trade Institute

Real-World Application: Building a Custom Shelving Unit

Consider a homeowner installing floating shelves in a living room using 3/4” birch plywood. The job requires eight identical rip cuts and four clean crosscuts at 45-degree angles for mitered corners. Using a standard corded circular saw without a guide leads to inconsistent widths and visible tear-out on the veneer surface.

In contrast, when the same task is performed with a Makita XSS02Z paired with a straight-edge track guide, each cut aligns perfectly. The L.E.D. projection ensures the user doesn’t drift off-line, while the adjustable depth setting minimizes blowout on the backside of the panel. Bevel adjustments are locked in place with detents at common angles, eliminating guesswork. The result? Professional-looking shelves installed in half the time, with minimal sanding required.

This example illustrates how investing in a precise, well-designed circular saw pays dividends not only in accuracy but also in workflow efficiency.

How to Maximize Cutting Accuracy: A Step-by-Step Guide

To get the most from your circular saw—regardless of model—follow this proven process for achieving clean, exact cuts every time:

- Select the right blade: Use a fine-tooth crosscut blade (60+ teeth) for sheet goods and a combination blade (40–50 teeth) for general framing and trim work.

- Mark both edges of your cut line: Transfer the measurement to both sides of the board so you can verify alignment during the cut.

- Use a clamped straightedge or track guide: Never rely solely on eyeing the cut. Secure a level or dedicated guide rail with C-clamps to ensure a perfectly straight path.

- Set blade depth correctly: Adjust so the blade extends no more than 1/4 inch below the material thickness. This reduces vibration and improves safety.

- Check bevel angle with a digital gauge: Even if your saw has preset stops, verify the angle with an electronic protractor for critical joints.

- Cut slowly and steadily: Let the blade do the work. Forcing the saw causes binding, wandering, and rough edges.

- Support the workpiece fully: Use sawhorses or roller stands to prevent sagging, which can pinch the blade mid-cut.

Essential Checklist Before Buying

Before committing to a purchase, evaluate potential models against these criteria:

- ✅ Does it offer tool-free depth and bevel adjustments?

- ✅ Is the base plate made of die-cast metal (not stamped steel)?

- ✅ Does it include a dust blower or port for vacuum attachment?

- ✅ Can it accommodate a guide rail or auxiliary fence?

- ✅ Is there adequate lighting around the blade area?

- ✅ What is the warranty and battery ecosystem (for cordless models)?

- ✅ Are replacement blades readily available and affordable?

For contractors who rotate between job sites, compatibility with an existing tool platform (e.g., DeWalt 20V MAX, Milwaukee M18) can save hundreds over time. For hobbyists, plug-in models like the Bosch CS7 remain cost-effective and powerful without requiring battery investments.

Frequently Asked Questions

Can a circular saw achieve the same precision as a table saw?

While a table saw offers superior repeatability for long rip cuts, a circular saw equipped with a track guide system (such as Festool’s Rail or Kreg’s Accu-Cut) can match its accuracy within 1/32 inch. For most on-site work, the difference is negligible.

What’s better: corded or cordless circular saws?

Corded models provide uninterrupted power and are ideal for stationary workshops. However, modern brushless cordless saws now deliver comparable torque and runtime (up to 100 cuts per charge in softwood). For mobility and convenience, cordless wins—especially on ladders or unfinished floors where cords pose tripping hazards.

How often should I replace the blade?

Replace or sharpen the blade when you notice burning marks, increased resistance, or ragged edges. As a rule of thumb, expect 6–12 months of regular use depending on material type. Carbide-tipped blades last longer but require professional sharpening.

Final Thoughts: Choosing Confidence Over Compromise

The best electric circular saw for precise cutting and versatile use isn’t defined by brand loyalty or price tag—it’s determined by consistency, adaptability, and user control. Whether you’re building furniture in a garage shop or framing walls on a renovation site, the right saw becomes an extension of your intent. Models like the Makita XSS02Z and DeWalt DCS570B exemplify how advanced engineering translates into real-world reliability.

Ultimately, precision begins before the blade spins. It starts with preparation, continues through proper technique, and is supported by intelligent tool selection. By prioritizing features that enhance visibility, stability, and adjustability, you equip yourself not just with a tool—but with confidence.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?