In regions where summer temperatures regularly exceed 100°F (38°C), vehicle owners face a constant battle against interior heat buildup. Sunlight streaming through car windows not only raises cabin temperature but also accelerates dashboard fading, increases air conditioning load, and reduces driving comfort. Window tinting has long been a go-to solution—but with multiple types on the market, one question stands out: Is the superior heat rejection of ceramic tint actually noticeable compared to regular tint, especially in hot climates?

The answer isn’t just marketing hype. Real differences in materials, construction, and infrared (IR) blocking capabilities make ceramic tints a compelling upgrade for drivers in sun-drenched areas. This article dives into the technical and experiential aspects of both options, backed by performance data, user experiences, and expert insights.

Understanding the Basics: What Is Ceramic Tint and Regular Tint?

Before comparing performance, it’s essential to understand what sets these two tints apart at a fundamental level.

Regular tint, often referred to as dyed or metallic film, typically consists of layers of polyester coated with dyes or metal particles. Dyed films absorb sunlight to reduce glare and visible light transmission, while metallic tints use aluminum or titanium particles to reflect some solar energy. However, their ability to block infrared radiation—the primary source of heat—is limited.

Ceramic tint, on the other hand, uses non-conductive, nano-ceramic particles embedded within the film. These particles are engineered to selectively block infrared and ultraviolet (UV) rays without interfering with radio or GPS signals. Unlike metallic films, ceramic tints do not interfere with electronics and offer superior heat rejection across the solar spectrum.

“Ceramic window films represent a significant leap in thermal control technology. They don’t just darken the glass—they actively combat heat at its source.” — Dr. Alan Reyes, Materials Scientist & Solar Control Consultant

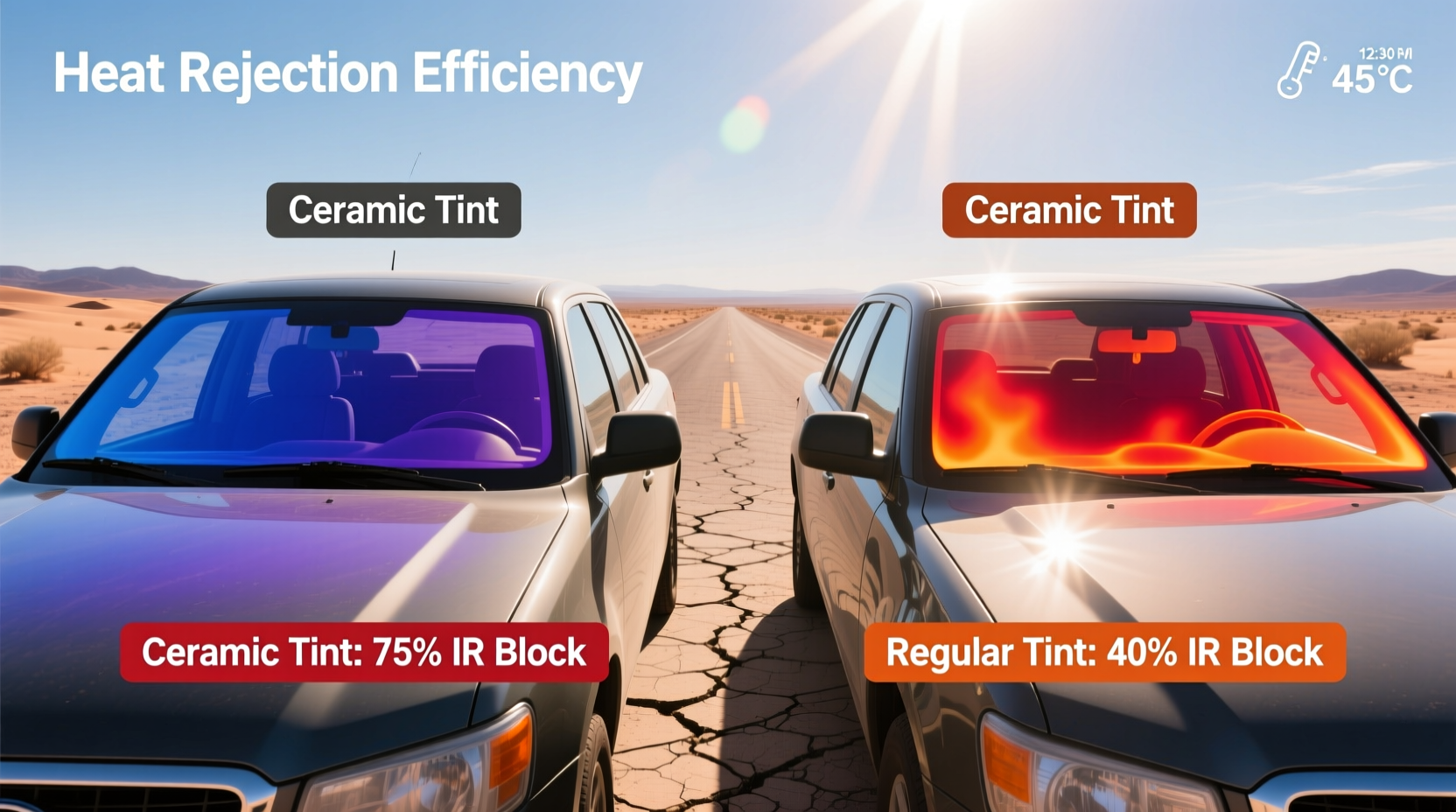

Heat Rejection Performance: The Numbers Behind the Comfort

When evaluating heat rejection, three key metrics matter:

- Solar Energy Rejection (TSER): Total percentage of solar energy blocked.

- Infrared (IR) Rejection: Percentage of IR radiation blocked (primary heat source).

- Visible Light Transmission (VLT): How much light passes through; affects visibility and darkness.

Let’s compare typical performance values between standard and ceramic tints at a common VLT of around 35%—a popular choice for balance between aesthetics and functionality.

| Tint Type | TSER (%) | IR Rejection (%) | VLT (%) | UV Protection |

|---|---|---|---|---|

| Dyed (Regular) | 30–40% | 20–35% | 35% | 98% |

| Metallic (Regular) | 40–50% | 40–50% | 35% | 99% |

| Ceramic | 55–70% | 85–95% | 35% | 99.9% |

The difference is stark. While both types may appear similarly dark, ceramic films reject up to twice as much infrared radiation—the invisible component responsible for over 50% of solar heat gain. This means that even if ambient light levels are comparable, the actual thermal experience inside the vehicle will differ significantly.

Real-World Experience: Is the Difference Noticeable?

Data is informative, but drivers care about tangible results. Does ceramic tint feel cooler when stepping into a car parked under the Arizona sun? Anecdotal evidence and controlled tests suggest yes—especially in extreme climates.

In Phoenix, where surface temperatures on dashboards can exceed 180°F (82°C), a comparative test was conducted using two identical sedans parked side-by-side for four hours at noon in July. One vehicle had high-quality ceramic tint applied; the other had standard dyed film. Interior readings showed:

- Dyed tint vehicle: Cabin temperature reached 148°F (64°C); steering wheel measured 165°F (74°C).

- Ceramic tint vehicle: Cabin temperature peaked at 126°F (52°C); steering wheel was 138°F (59°C).

A 22°F (12°C) reduction in cabin temperature is not subtle—it’s transformative. Drivers reported being able to sit inside the ceramic-tinted car immediately after parking, while the other required several minutes of ventilation and AC blasting before becoming tolerable.

“I used to keep a towel on the driver’s seat every summer. With ceramic tint, I haven’t needed it in two years—even after eight-hour workdays.” — Carlos Mendez, Tucson resident and daily commuter

Key Advantages of Ceramic Tint Beyond Heat Rejection

While heat reduction is the headline benefit, ceramic tints deliver additional advantages that enhance long-term value:

UV Protection and Interior Preservation

Ceramic films block over 99% of UV rays, significantly slowing the degradation of upholstery, dashboards, and trim. In sunny climates, this can delay cracking, fading, and warping by years.

No Signal Interference

Metallic tints can disrupt GPS, toll transponders, and mobile phone reception. Ceramic films are non-metallic, so they don’t interfere with electronic devices—a crucial factor for modern connected vehicles.

Clarity and Optical Quality

High-end ceramic tints offer superior clarity with minimal distortion, even at night. Some dyed or low-grade metallic films develop hazing or reflectivity issues over time, particularly in humid environments.

Durability and Fade Resistance

Ceramic particles are highly stable and resistant to breakdown from UV exposure. Unlike dyed films that may turn purple or bubble after years of sun exposure, quality ceramic tints maintain appearance and performance for a decade or more.

Cost Considerations: Is Ceramic Tint Worth the Investment?

Ceramic tint typically costs 20–50% more than premium metallic or dyed films. For a full vehicle application, expect to pay $400–$800 for ceramic versus $250–$500 for regular high-end tint.

However, the return on investment becomes clear in hot climates:

- Fuel efficiency: Reduced AC usage lowers engine load, improving fuel economy by up to 5% in stop-and-go traffic.

- Comfort: Lower cabin temperatures improve ride comfort, especially for children and pets.

- Interior protection: Delaying dashboard replacement or reupholstering saves hundreds over time.

For residents of Texas, Florida, Nevada, or the Middle East, the added upfront cost is often justified within 2–3 years through improved comfort and reduced wear.

Checklist: Choosing the Right Tint for Your Climate

- Assess your local climate: Average highs above 90°F (32°C)? Prioritize IR rejection.

- Determine legal VLT limits in your state or country.

- Verify whether metallic tints interfere with your vehicle’s electronics.

- Request TSER and IR rejection specs—not just VLT—from installers.

- Choose a reputable installer who offers a warranty and uses authentic film.

- Consider long-term durability: Will the film resist bubbling and fading?

Installation and Maintenance Best Practices

Even the best ceramic film underperforms if poorly installed. Proper adhesion, edge sealing, and curing time are critical. Most professionals recommend avoiding window operation for 48–72 hours post-installation to allow full bonding.

Maintenance is straightforward:

- Clean with ammonia-free solutions to prevent adhesive breakdown.

- Use microfiber cloths to avoid scratching.

- Avoid abrasive cleaners or squeegees with metal edges.

Unlike older films, ceramic tints do not require special care beyond routine cleaning. Their scratch-resistant coatings hold up well to regular use.

FAQ: Common Questions About Ceramic vs Regular Tint

Does ceramic tint make a difference at night?

No significant difference in visibility. In fact, because ceramic films manage glare without excessive reflectivity, many users report better night vision compared to mirrored metallic tints.

Can I apply ceramic tint over existing film?

No. Layering tints traps moisture, causes bubbling, and violates most manufacturer warranties. Old film must be completely removed before new installation.

How long does ceramic tint last?

Most high-quality ceramic films carry lifetime or 10-year warranties and can last 12–15 years under normal conditions. They resist fading, bubbling, and peeling far better than dyed alternatives.

Conclusion: Making the Smart Choice for Hot Climates

In consistently hot environments, the enhanced heat rejection of ceramic tint isn't just measurable—it's unmistakable. The combination of superior infrared blocking, long-term durability, and electronic compatibility makes it a standout upgrade over traditional dyed or metallic films. While the initial cost is higher, the benefits in comfort, vehicle preservation, and energy efficiency deliver tangible returns over time.

If you live where summers are long and intense, investing in ceramic window tint is less about luxury and more about practical climate control. It transforms your car from a sweltering oven into a cooler, safer, and more pleasant space—all without altering your vehicle’s appearance dramatically.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?