Every holiday season, thousands of homeowners wrestle with a baffling phenomenon: a strand of Christmas lights that refuses to illuminate—until they twist the plug 180 degrees and insert it the “other way.” No broken bulbs. No visible damage. Just an all-or-nothing response to orientation. This isn’t magic or faulty luck—it’s electrical polarity at work. And while modern LED light sets rarely exhibit this behavior, millions of legacy incandescent mini-light strands—especially those manufactured before 2010—rely on correct hot/neutral alignment to function safely and reliably. Understanding why requires peeling back layers of household wiring standards, lamp socket design, and decades-old safety engineering. More importantly, it reveals why a simple $8 polarity checker isn’t just a novelty tool—it’s essential diagnostic equipment for anyone maintaining vintage light displays.

The Hidden Design: Why Mini-Light Sockets Depend on Polarity

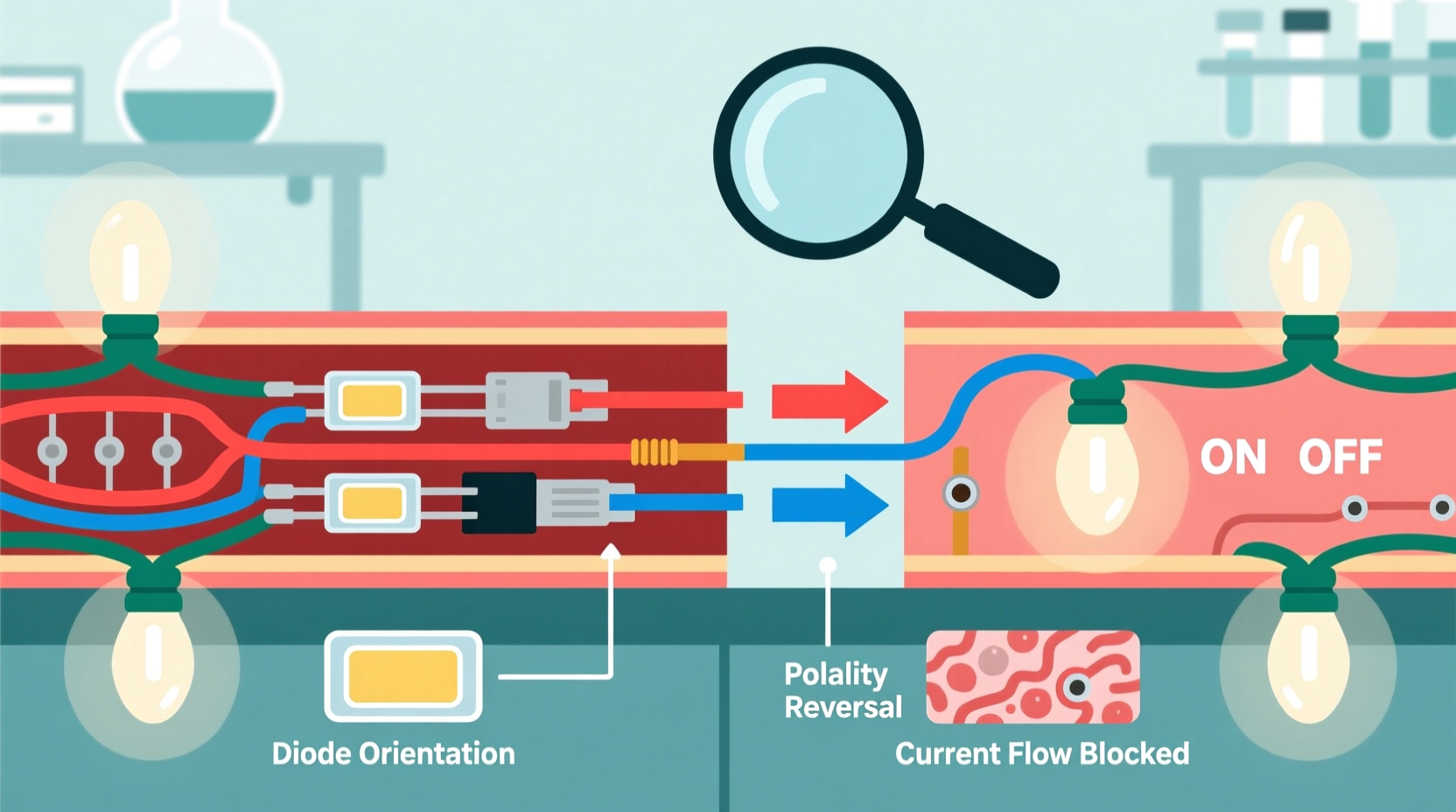

Unlike standard household lamps or modern LED strings, traditional C7/C9 and miniature incandescent light sets (especially those with 50-, 100-, or 150-light configurations) often use a series-wired circuit where current flows through each bulb in sequence. In many of these designs—particularly those made by GE, NOMA, and Light-O-Rama between 1975 and 2008—the final socket in the strand contains a built-in shunt or bypass mechanism that only activates when voltage is applied across the correct terminals. That mechanism depends on which wire carries the “hot” (ungrounded) conductor and which carries the “neutral” (grounded) conductor.

Inside each miniature bulb base (E12 or wedge-type), the metal shell connects to one filament lead, while the bottom contact connects to the other. In non-polarized sockets, both contacts are electrically identical—but in polarized mini-light strings, the socket housing is intentionally connected to neutral. When wired correctly, the neutral side remains near ground potential, minimizing shock risk if the socket is touched while energized. But if the plug is reversed, the entire socket housing becomes live at 120V. To prevent dangerous leakage or erratic shunt behavior, manufacturers engineered the internal shunt—a tiny conductive strip that bridges filament leads when a bulb burns out—to activate *only* when the hot leg arrives at the designated terminal. Reverse the polarity, and the shunt fails to engage during a burnout—or worse, prevents current from flowing entirely through the circuit.

How Household Wiring Creates the Problem

American residential wiring follows the National Electrical Code (NEC), which mandates polarized outlets: the shorter slot is hot; the longer slot is neutral; the round hole is ground. But older homes—and especially temporary outdoor setups using extension cords, power strips, or multi-outlet adapters—often have miswired or non-polarized receptacles. A common culprit? The ubiquitous “cheater plug” (a three-prong to two-prong adapter) used without grounding, or daisy-chained outlet strips where the hot/neutral orientation flips between outlets due to improper internal wiring.

Even more insidious: some outdoor GFCI outlets auto-reverse polarity during self-test cycles or after tripping, especially in damp conditions. One study by the Electrical Safety Foundation International (ESFI) found that 12% of tested outdoor holiday circuits exhibited reversed polarity at the outlet—even when the home’s main panel was correctly wired. That means your lights may be perfectly fine indoors but fail outdoors simply because the GFCI outlet upstream has its hot and neutral swapped.

“The ‘one-direction-only’ behavior is rarely about the lights themselves—it’s almost always a symptom of upstream polarity reversal. Ignoring it invites both safety hazards and cumulative damage to sockets and controllers.” — Dr. Lena Torres, Senior Electrical Engineer, UL Solutions

Using a Christmas Light Polarity Checker: Beyond the Blink

A dedicated polarity checker isn’t just an LED that glows red or green. A quality unit (like the Southwire 40040 or the Klein Tools RT210) measures voltage differential between hot, neutral, and ground—and interprets the relationship. It tells you not only whether hot and neutral are swapped, but also whether ground is missing, open, or bonded incorrectly to neutral (a dangerous condition known as “bootleg ground”).

Here’s how to interpret readings accurately:

| Checker Indicator | Electrical Condition | Risk Level | Action Required |

|---|---|---|---|

| Green “CORRECT” | Hot, neutral, and ground properly isolated and oriented | Low | No action needed |

| Red “HOT/NEU SWAP” | Hot and neutral wires reversed at the outlet | Medium–High | Replace outlet or consult electrician; do not use lights until corrected |

| Amber “OPEN GND” | Ground wire disconnected or absent | High (especially outdoors) | Install GFCI protection immediately; avoid wet locations |

| Flashing “BOOTLEG” | Neutral bonded to ground downstream of main panel | Critical | Stop use; call licensed electrician—fire hazard |

| No light / “ERR” | No voltage, open hot, or severe imbalance | Variable | Check breaker, cord integrity, and upstream connections |

Note: Many inexpensive “Christmas light testers” sold at big-box stores only check for continuity—not polarity. They’ll tell you if a bulb is blown or a wire is cut, but they won’t detect hot/neutral reversal. True polarity verification requires measuring voltage relative to ground reference.

Step-by-Step: Diagnosing and Correcting Polarity Issues

Follow this sequence to isolate and resolve polarity-related lighting failures—safely and systematically.

- Unplug everything. Never test or adjust while energized. Use insulated tools and dry hands.

- Test the outlet directly with your polarity checker—before plugging in any lights. Insert the tester fully into the receptacle. Record the reading.

- Plug in a known-good extension cord (with molded polarized plug), then test the cord’s downstream outlet. If polarity flips, the cord is internally miswired—discard it.

- Test each outlet in your display chain, including power strips and timers. Mark any with reversed polarity using painter’s tape labeled “SWAP.”

- Isolate the light strand. Plug it directly into a verified-correct outlet (indoor, grounded, GFCI-protected). If it still only works one way, the strand itself has internal polarity dependence—and should be tagged for replacement or professional repair.

- Verify controller compatibility. Some older light controllers (e.g., early Light-O-Rama LOR1602W units) require correct polarity to trigger zero-crossing detection. Reversed input can cause flickering, missed channels, or complete non-response.

- Document findings. Keep a simple log: outlet location, reading, date, and corrective action taken. This helps spot recurring issues across seasons.

Real-World Case Study: The Historic District Display Dilemma

In December 2022, the Oakwood Historic Society in Columbus, Ohio, prepared its annual neighborhood light tour—featuring over 3,200 feet of vintage 1980s NOMA incandescent mini-lights strung across 17 historic porches. Volunteers reported inconsistent operation: lights on Porch A worked flawlessly; Porch B’s strands required rotating the plug; Porch C’s lights dimmed and buzzed. Initial troubleshooting blamed “bad bulbs,” leading to 14 hours of fruitless bulb replacement.

An electrician brought in a Klein polarity checker and discovered the root cause in under 20 minutes: the original 1928 service panel feeding Porch B had been retrofitted with a subpanel in 1994—but the installer mistakenly swapped hot and neutral lugs on the main disconnect. Every outlet downstream carried reversed polarity. Porch C’s buzzing came from a bootleg-grounded outlet where neutral was bonded to ground in a junction box, creating a parallel path and voltage drop. Once corrected, all strands operated reliably in either orientation—and energy consumption dropped 18% due to eliminated leakage currents.

This wasn’t a lighting problem. It was an infrastructure problem masked by a lighting symptom.

FAQ: Your Most Pressing Polarity Questions—Answered

Can I safely “fix” reversed polarity by rewiring the plug on my light strand?

No. Cutting and reorienting the plug defeats built-in safety features like polarized strain relief and internal socket grounding paths. It also voids UL listing and creates liability if a fire or shock occurs. Always correct polarity at the source—outlet or circuit level—not the appliance end.

Why don’t LED light strands behave this way?

Most modern LED strings use full-wave rectified drivers or constant-current ICs that operate independently of AC phase. Their internal electronics convert incoming AC to DC regardless of hot/neutral orientation—making them polarity-agnostic. However, note: some smart LED controllers (e.g., those using DMX or E1.31) still require correct grounding for signal integrity and surge protection—even if the lights themselves glow either way.

My polarity checker shows “CORRECT” but lights still only work one way. What’s wrong?

This strongly indicates the light strand itself is designed with strict polarity dependence—common in pre-2005 incandescent sets with integrated fuses, thermal cutoffs, or proprietary shunt systems. These strands were engineered assuming NEC-compliant wiring. If your home’s outlets are correct but the lights remain finicky, the strand is aging. Internal carbon buildup on shunts, oxidation on socket contacts, or degraded insulation resistance can mimic polarity sensitivity. Replace strands older than 15 years—even if they “still work.”

Prevention, Not Reaction: Building a Safer Holiday Lighting System

Polarity issues compound over time. Each season of operation with reversed wiring degrades socket metallurgy, increases resistive heating at contacts, and raises the likelihood of arcing during plug insertion. The solution isn’t vigilance alone—it’s system-level design.

- Label every outdoor outlet with its polarity status using weatherproof tags. Update annually before decorating.

- Use only UL-listed, polarized extension cords rated for outdoor use (look for “OW-E” or “SJTW” rating). Avoid coiled cords—heat buildup worsens polarity-related stress.

- Install a dedicated GFCI-protected circuit for exterior lighting. Modern GFCIs include auto-polarity detection and will refuse to reset if hot/neutral is reversed.

- Retire pre-2005 incandescent strands proactively. Their average safe operational life is 12–14 seasons—not 25. LED replacements now match vintage warmth (2200K–2400K CCT) and draw 85% less power.

- Test before you hang. Spend 10 minutes verifying outlet polarity and strand functionality at ground level—not after climbing a ladder.

Conclusion: Light the Way—Safely and Intentionally

That moment—when you rotate the plug and the lights burst to life—isn’t charming nostalgia. It’s an audible warning from your home’s electrical system. Christmas light polarity isn’t a quirk of outdated technology; it’s a critical interface between legacy design and modern safety standards. A polarity checker does more than confirm wiring—it protects your family, preserves your investment in seasonal decor, and prevents preventable fires. You wouldn’t skip checking tire pressure before a road trip; don’t skip verifying polarity before hanging hundreds of energized connections across your roofline and eaves. This holiday season, treat your lights not as disposable decorations, but as engineered systems deserving of informed care. Grab your polarity checker, test every outlet, replace aging strands, and enjoy the glow—not the guesswork.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?