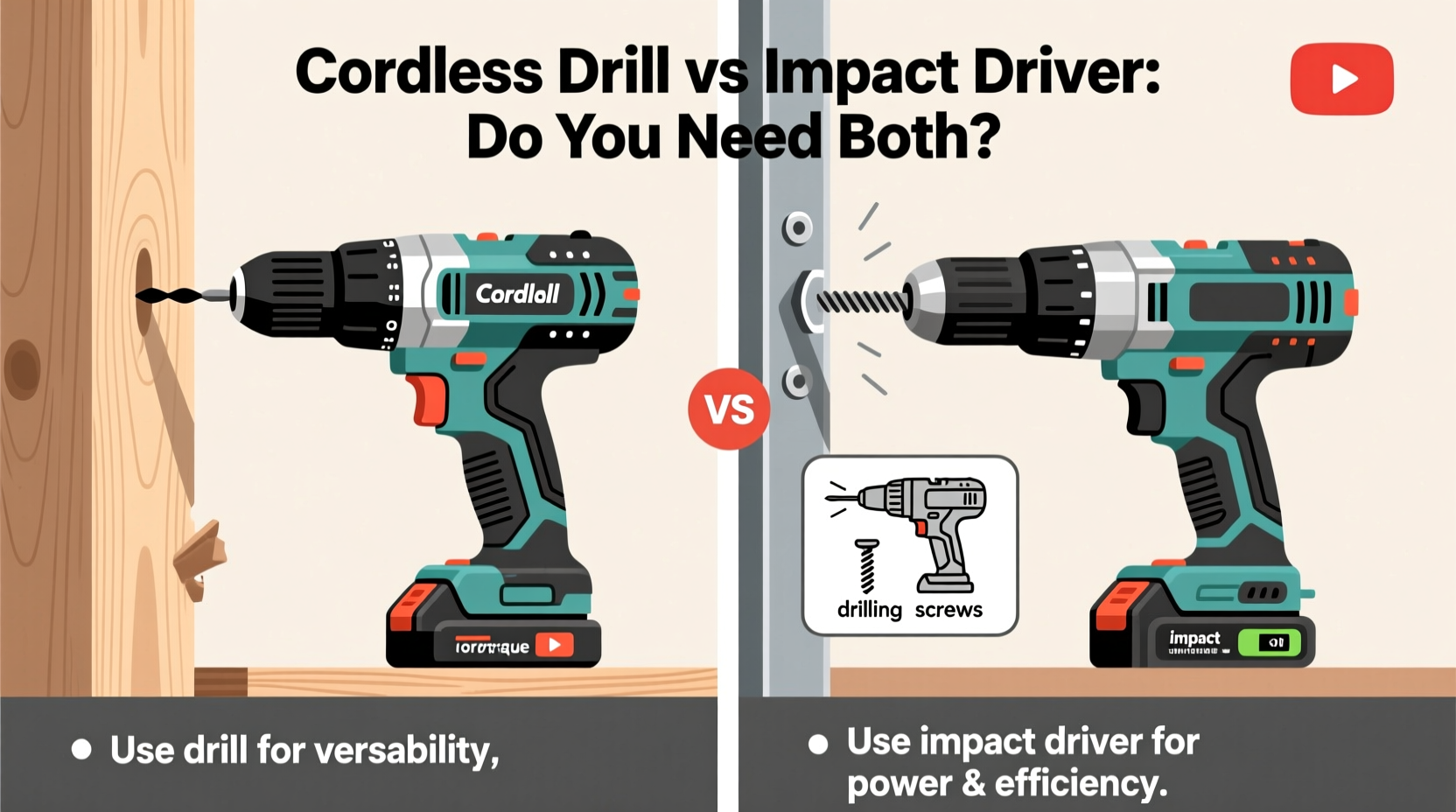

For homeowners and weekend warriors tackling everything from shelving installations to deck repairs, power tools are essential. Two of the most common tools found in modern toolkits are the cordless drill and the impact driver. At first glance, they look similar—compact, battery-powered, and designed to drive screws or drill holes. But their internal mechanics, torque delivery, and ideal applications differ significantly. Understanding these differences is crucial for choosing the right tool—and deciding whether you truly need both for your DIY needs.

Understanding the Core Differences

The confusion between a cordless drill and an impact driver often starts with their outward similarity. Both are handheld, powered by lithium-ion batteries, and feature hex-shaped chucks or bits. However, their performance under load reveals their distinct purposes.

A **cordless drill** is primarily designed for precision tasks such as drilling holes in wood, metal, or plastic, and driving smaller screws. It delivers consistent rotational force (torque) with variable speed control, allowing users to adjust settings based on material and screw size. Most models come with a clutch system that disengages once a preset torque level is reached, preventing over-tightening and damage to screw heads or materials.

An **impact driver**, on the other hand, is built for high-torque applications. Instead of relying solely on rotation, it combines rotational force with concussive blows—thousands of tiny hammering actions per minute—delivered directly along the axis of the bit. This allows it to drive long lag bolts into hardwood, loosen rusted fasteners, or work with high-strength screws without stripping or stalling.

Performance Comparison: Where Each Tool Excels

To make informed decisions, consider how each tool performs across key categories.

| Feature | Cordless Drill | Impact Driver |

|---|---|---|

| Torque Delivery | Smooth, continuous rotation | Rotational + percussive impacts (up to 50,000 IPM) |

| Chuck Type | Keyed or keyless (usually 3/8\") | Hex collet (1/4\") – accepts bits directly |

| Speed Control | Variable speed trigger + clutch settings | Variable speed only – no clutch |

| Best For | Drilling holes, pilot holes, light screwdriving | Driving long screws, lag bolts, structural fasteners |

| Size & Weight | Slightly bulkier, heavier | More compact, better balance |

| Over-Tightening Risk | Low (thanks to clutch) | Higher – requires user control |

The absence of a clutch in impact drivers means they rely entirely on user technique to avoid damaging materials or fasteners. While this makes them less forgiving on delicate jobs, it also enables unmatched power in demanding applications like framing, decking, or working with composite materials.

“An impact driver isn’t just a stronger drill—it’s a different animal altogether. The way it delivers force lets you drive 3-inch screws into oak without pre-drilling, which would stall most drills.” — Mark Reynolds, Professional Carpenter & Tool Instructor

Real-World Scenarios: When You Need One or the Other

Let’s examine two common DIY scenarios to illustrate when each tool shines—and whether having both adds real value.

Scenario 1: Installing Floating Shelves in Drywall

You’re mounting floating shelves in your living room using toggle bolts and wall anchors. The job involves drilling pilot holes into drywall and wood backing, then driving medium-sized screws.

- Tool Choice: Cordless drill

- Why: Precision matters here. You need controlled torque to avoid cracking drywall or over-driving screws. The drill’s clutch ensures consistent results, and its ability to switch between drill and drive modes streamlines the process.

- Impact Driver Drawback: Too much power. Without a clutch, it could easily strip screws or damage surrounding drywall.

Scenario 2: Building a Deck Frame with Pressure-Treated Lumber

You're assembling a deck frame using 3-inch structural screws and 2x6 joists. The wood is dense, and some screws require significant force to seat properly.

- Tool Choice: Impact driver

- Why: High torque and impact action prevent cam-out (slipping from the screw head), reduce wrist strain, and eliminate the need for pre-drilling in most cases. You’ll complete the job faster and with fewer stripped bits.

- Cordless Drill Limitation: Even a high-torque drill may stall or overheat when driving multiple long screws into tough lumber.

Do You Actually Need Both Tools?

This is the central question for most DIYers: Can one tool handle all jobs, or is dual ownership justified?

In short: Yes, many serious DIYers benefit from owning both. Here’s why:

- Efficiency Across Projects: Owning both tools eliminates compromises. You won’t be forcing a drill into impact-level tasks or using an impact driver for fine adjustments.

- Battery Platform Compatibility: Most major brands (DeWalt, Milwaukee, Makita, Ryobi) offer both drills and impact drivers within the same battery ecosystem. Once you invest in one 18V or 20V MAX system, adding a second tool doesn’t require new chargers or extra batteries.

- Ergonomic Advantages: Impact drivers are typically shorter and lighter, making them easier to maneuver in tight spaces like between studs or under cabinets. Drills, while bulkier, offer better visibility and control for drilling.

- Long-Term Cost Savings: Using the right tool extends bit life, reduces screw waste, and prevents damage to materials—saving money over time.

That said, if your DIY work is limited to light assembly, furniture building, or occasional repairs, a mid-range cordless drill with at least 400 in-lbs of torque may suffice. Pair it with quality bits and proper technique, and it can handle moderate fastening tasks reasonably well.

However, if you plan to tackle outdoor structures, home renovations, or any project involving thick lumber, metal brackets, or concrete anchors, an impact driver becomes far more than a luxury—it becomes a necessity.

Checklist: Choosing the Right Tool for Your Needs

Use this checklist to determine whether you should buy one or both tools:

- ✅ Do you frequently drive long screws (>2 inches) into hardwood or engineered lumber? → Impact driver recommended

- ✅ Do you need to drill precise holes in various materials (wood, metal, masonry)? → Cordless drill essential

- ✅ Are you working on large-scale projects like decks, fences, or shed builds? → Both tools strongly advised

- ✅ Is storage space or budget extremely limited? → Start with a versatile drill-driver combo kit

- ✅ Do you value reduced physical effort and faster completion times? → Impact driver improves workflow significantly

Step-by-Step Guide: Setting Up Your Dual-Tool System

If you decide to go the dual-tool route, follow this practical setup guide:

- Choose a Brand Ecosystem: Pick a reputable brand (e.g., DeWalt 20V MAX, Milwaukee M18, Ryobi ONE+) that offers both tools and shares batteries.

- Select a Drill: Opt for a compact 12V or standard 18V/20V model with at least two-speed gears and a clutch with 15+ settings.

- Select an Impact Driver: Look for at least 1,500 in-lbs of torque and a compact length (under 6 inches) for better access.

- Buy Shared Batteries: Start with two batteries and one charger. Use one battery while charging the other.

- Invest in Quality Bits: Purchase S2 steel or impact-rated bits. Avoid cheap hardware store sets—they wear quickly.

- Label and Organize: Keep drill bits and impact bits separate. Store tools in a durable bag or rack for quick access.

Frequently Asked Questions

Can I use an impact driver to drill holes?

Only in soft materials like wood or plastic, and even then, only with specific bits. Impact drivers lack the precision and chuck grip needed for reliable drilling. They are not designed for masonry or metal drilling. Always use a cordless drill for accurate hole-making.

Is an impact driver safer than a drill?

Not inherently. While impact drivers reduce user fatigue, their high torque increases the risk of injury if the bit binds and the tool kicks back. Always maintain a firm grip, wear safety glasses, and keep hands clear of rotating parts.

Can I replace my cordless drill with an impact driver?

No—not fully. An impact driver excels at driving but fails at controlled drilling and light fastening. A cordless drill offers versatility, precision, and clutch protection that an impact driver lacks. They complement each other rather than serve as substitutes.

Final Recommendation: Build Smart, Not Just Strong

DIY success isn’t just about completing a project—it’s about doing so efficiently, safely, and with professional-quality results. The cordless drill and impact driver fulfill different but equally important roles in that journey. Think of the drill as your everyday multitasker and the impact driver as your specialized powerhouse.

While beginners might start with a single cordless drill, advancing to more complex projects naturally leads to the need for both tools. The investment pays off in saved time, reduced frustration, and cleaner outcomes. And thanks to shared battery platforms, expanding your toolkit has never been more affordable or convenient.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?