Cardboard is one of the most accessible and versatile materials for DIY projects, packaging, and storage solutions. Yet, many people discard offcuts when resizing boxes, contributing to unnecessary waste. With thoughtful planning and clever construction methods, it’s entirely possible to create a smaller box from a larger one—without throwing anything away. Whether you're repurposing shipping boxes or designing custom containers for home organization, these techniques help maximize material use while minimizing environmental impact.

Design with Intention: Plan Before You Cut

The key to zero-waste cardboard box reduction lies in foresight. Instead of making arbitrary cuts, start by measuring your desired dimensions and mapping them onto the existing box. Use a ruler and pencil to sketch out how the new box will form from the original panels. Consider which flaps can become sides, tops, or internal reinforcements. By visualizing the transformation first, you avoid irreversible mistakes and preserve usable scraps for future applications.

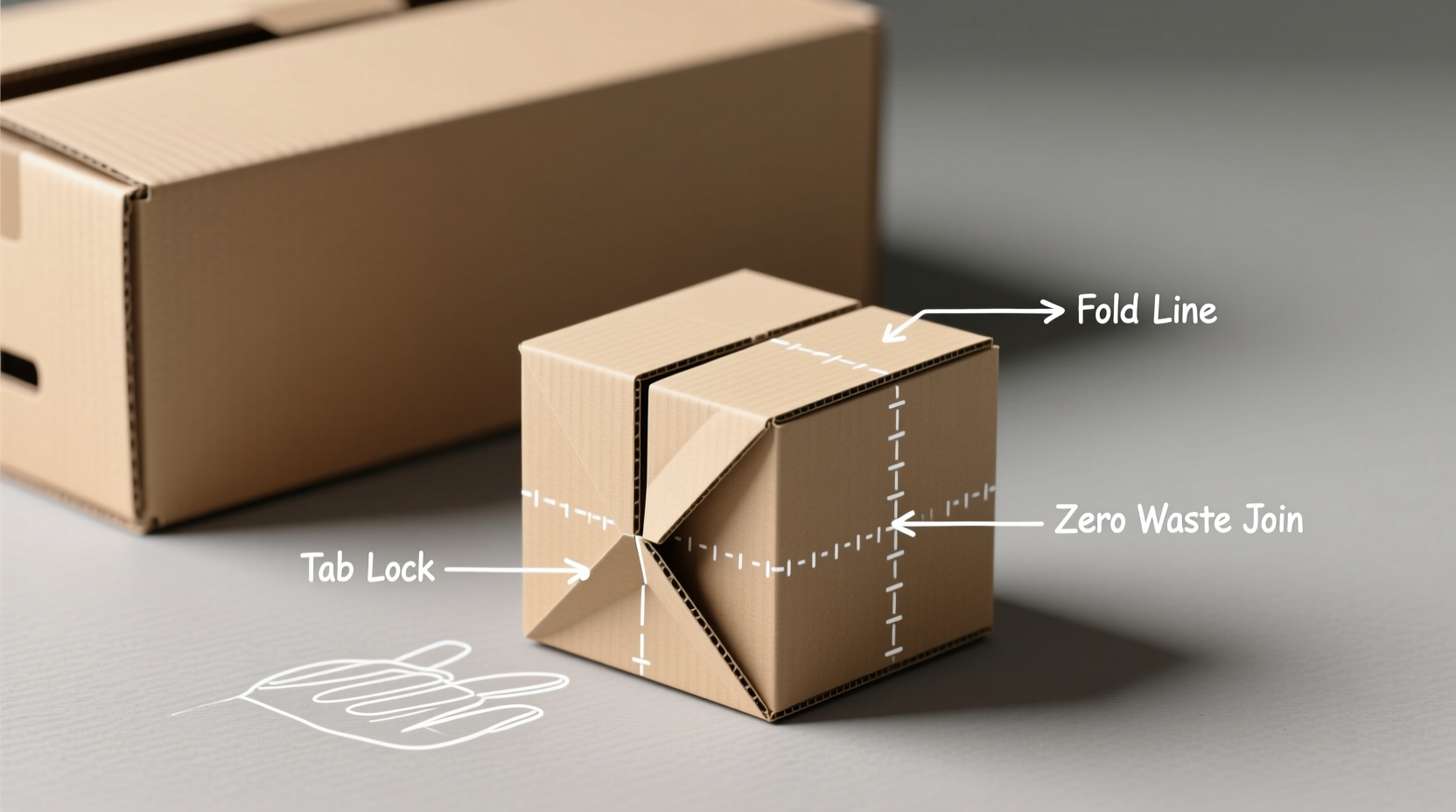

Modular Folding Technique

This method relies on folding rather than removing material. Begin with a standard rectangular box and identify where you want to reduce height or width. Score the cardboard along the fold lines using a utility knife (lightly, just through the top layer) at intervals equal to the amount you wish to shrink. Then, collapse the scored section inward, tucking it neatly inside the box structure. Reinforce folds with tape or glue if needed.

For example, if reducing box height by 3 inches, score all four side panels 3 inches from the top. Fold these sections down and inward so they nest within the lower portion. The former top flaps now act as internal braces, adding rigidity without requiring additional materials.

Interlocking Panel Reuse

When downsizing requires cutting, never discard the removed sections. Instead, transform them into interlocking joints or support elements. Cut strips from excess pieces to serve as corner braces or cross-bracing for the new box base. These inserts improve durability and eliminate the need for external reinforcements like plastic ties or metal brackets.

A practical approach involves slicing leftover cardboard into L-shaped corner guards. Attach them internally at each vertical seam using non-toxic adhesive or paper-based tape. This not only strengthens the structure but also consumes every usable inch of the original material.

Step-by-Step Guide: Transform a Large Box Into a Smaller One Without Waste

- Measure and mark the target dimensions on the original box, ensuring alignment across all sides.

- Score fold lines instead of cutting wherever possible, preserving continuity of the surface.

- Fold inward excess sections and secure with biodegradable tape or flour paste.

- Cut necessary removals only after confirming no alternative folding option exists.

- Repurpose offcuts into corner supports, dividers, or lid fasteners.

- Reinforce weak points using layered scraps glued between inner and outer walls.

- Test structural integrity by gently pressing on sides and lifting the completed box.

Zero-Waste Material Allocation Table

| Original Component | New Function | Assembly Method |

|---|---|---|

| Side Panels (reduced) | Main walls of smaller box | Folded and taped internally |

| Top Flaps | Internal bracing or lid reinforcement | Glued beneath new lid line |

| Bottom Section (excess) | Floor insert or stacking feet | Cut into discs or squares |

| Edge Trimmings | Corner stabilizers or labels | Taped inside seams or written on |

Mini Case Study: Urban Apartment Organizer Project

In a small Berlin apartment, designer Lena Müller faced limited storage space and an accumulation of delivery boxes. Rather than recycling intact cartons, she developed a system to convert large Amazon shipments into compact drawer-style organizers for her closet. Using the modular folding technique, she reduced box heights by 40%, turning upper sections into sliding lids and side flaps into divider walls. Every scrap under 2x2 inches was pulped into homemade glue or used as packing filler for mailed gifts. Over six months, this method eliminated her need to buy plastic bins and diverted over 35 boxes from recycling streams.

“Waste isn’t inherent in cardboard—it’s a result of poor design thinking. When we treat material as finite, innovation follows.” — Dr. Armin Weiss, Sustainable Packaging Researcher, TU Darmstadt

Checklist: Zero-Waste Box Downsizing Protocol

- ☐ Measure final box size precisely before altering the original

- ☐ Prioritize folding over cutting to retain structural integrity

- ☐ Keep all cut pieces sorted by size and thickness

- ☐ Assign functional roles to every offcut (braces, labels, spacers)

- ☐ Use eco-friendly adhesives and tapes to align with sustainability goals

- ☐ Test load capacity after assembly to ensure safety

- ☐ Document the process for repeatable results in future projects

Advanced Technique: Nested Box System

For those seeking maximum utility, consider creating a nested box set. From a single large container, craft two or more progressively smaller boxes that fit inside one another. Start by trimming the top third of the original box to form a shallow tray. Use the middle section to build a medium-sized cube with folded flaps, and the bottom portion to assemble a compact storage unit with added dividers made from edge trimmings. Each level serves a different purpose—display, transport, or archival—while collectively consuming 100% of the source material.

This system excels in retail sampling kits, gift packaging, and educational toolsets, where layered presentation enhances user experience. Because no part goes unused, it exemplifies circular design principles in everyday contexts.

FAQ

Can I reuse tape remnants from the original box?

Yes, carefully peel off old tape and reapply it to internal seams where appearance doesn’t matter. Alternatively, soak adhesive-backed strips in warm water to separate fibers for papier-mâché projects.

What tools do I need for precise scoring?

A straightedge ruler and a blunt scoring tool (like a butter knife or empty ballpoint pen) work best. Avoid deep cuts; the goal is to crease the liner without breaking the backing sheet.

How strong will the modified box be compared to a factory-made one?

With proper reinforcement—especially using layered corners and internal bracing—a repurposed box can match or exceed commercial equivalents in durability, particularly for light to medium loads up to 15 lbs.

Conclusion

Making a smaller box from cardboard without waste isn’t just about frugality—it’s a mindset shift toward resourcefulness and ecological responsibility. By embracing folding over cutting, repurposing every fragment, and designing with full lifecycle awareness, anyone can turn discarded packaging into functional, attractive containers. These techniques are scalable, cost-free, and adaptable to homes, classrooms, and small businesses alike.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?