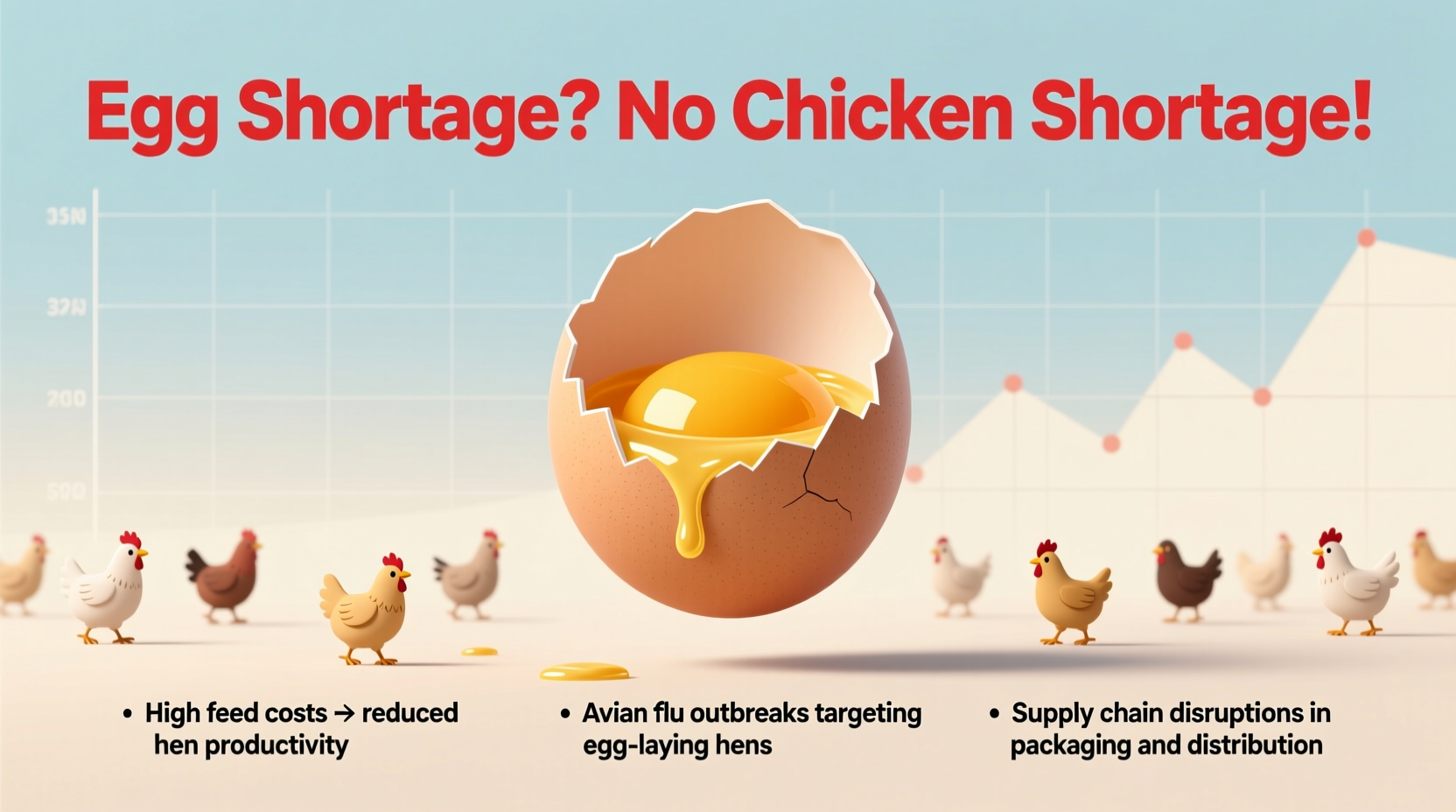

In recent years, consumers across the U.S. and other countries have faced repeated disruptions at the grocery store: empty shelves where cartons of eggs should be. What’s more puzzling is that despite widespread reports of egg shortages, there hasn’t been a noticeable reduction in the number of chickens raised for egg production. So what gives? Why can there be an egg shortage without a chicken shortage?

The answer lies not in the total number of hens but in a complex web of biological, economic, logistical, and regulatory factors. While the overall flock size may remain stable or even grow, disruptions at key points in the supply chain—from disease outbreaks to processing delays—can severely limit the number of eggs reaching consumers. This article breaks down the real causes behind the disconnect between chicken populations and egg availability.

Disease Outbreaks: The Hidden Threat to Egg Supply

The most significant factor behind recent egg shortages has been avian influenza, commonly known as bird flu. Since 2022, highly pathogenic strains of H5N1 have swept through commercial poultry farms across North America and Europe. Unlike diseases that merely reduce egg production, avian flu is often fatal to birds and requires mass culling to prevent further spread.

Even though new hens are continually being raised to replenish flocks, the timeline from chick to laying hen takes about 18–24 weeks. During this gap, egg production drops sharply. In 2022 alone, over 58 million birds were affected in the U.S., leading to the largest animal health incident in American history, according to the USDA.

“Avian flu doesn’t just kill birds—it disrupts the entire breeding and rearing pipeline. It takes months to rebuild a layer flock, and during that time, supply simply can’t meet demand.” — Dr. Karen Davis, Poultry Health Specialist, University of California, Davis

Additionally, biosecurity measures slow down operations. Farms under quarantine restrict movement of workers, equipment, and transport vehicles, delaying egg collection and delivery—even if unaffected barns are nearby.

Economic Pressures on Farmers and Processors

Raising laying hens is expensive. Feed costs account for up to 70% of operational expenses, and since 2020, corn and soy prices have risen significantly due to climate disruptions and global trade shifts. At the same time, labor shortages in rural areas make it harder to staff large-scale egg facilities.

Smaller farms, particularly those producing specialty eggs (organic, free-range), are especially vulnerable. Many exited the market during price spikes, reducing niche supply without affecting overall chicken numbers. Larger producers may maintain flock sizes but choose not to expand due to uncertain returns.

Moreover, some farmers hold back eggs from the market during high-price periods, storing them for later sale when margins improve. This strategic withholding reduces shelf availability temporarily, mimicking a shortage even when production continues.

Processing and Distribution Bottlenecks

A lesser-known but critical issue is the fragility of the egg processing infrastructure. Eggs must be collected, cleaned, graded, packed, and shipped rapidly—often within 24 to 48 hours of laying. Any disruption in this chain causes delays or spoilage.

Many processing plants operate near capacity. When one facility shuts down due to worker illness, mechanical failure, or contamination concerns, thousands of eggs per day go unprocessed. Unlike meat, which can be frozen and stored long-term, fresh shell eggs have a limited shelf life, making overflow storage impractical.

Transportation issues compound the problem. A shortage of refrigerated trucks or fuel price spikes can delay deliveries. Retailers may receive inconsistent shipments, leading to temporary outages even if national supply is adequate.

| Factor | Impact on Egg Supply | Time Lag to Recovery |

|---|---|---|

| Avian Influenza | Mass culling, reduced laying flocks | 4–6 months |

| Feed Costs | Reduced profitability, slower flock expansion | Ongoing |

| Processing Delays | Unprocessed eggs, spoilage | Days to weeks |

| Labor Shortages | Slower collection and packing | Variable |

| Transportation Issues | Delayed or missed deliveries | Days |

Consumer Demand Spikes: The Panic Effect

When news of an impending shortage spreads, consumers often respond by buying in bulk. A single family purchasing five dozen eggs instead of one creates artificial demand pressure. Retailers struggle to keep shelves stocked, triggering more panic buying—a self-reinforcing cycle.

Holidays amplify this effect. Around Thanksgiving and Easter, egg usage surges for baking and traditional dishes. If supply is already constrained, even normal seasonal demand can lead to empty shelves. In early 2023, average U.S. retail egg prices peaked at over $4.00 per dozen—more than double pre-crisis levels—driving hoarding behavior.

“We saw customers buying 10 cartons at a time. That kind of spike isn’t sustainable. One person’s holiday pie uses what would feed a small farm’s weekly output.” — Maria Thompson, Grocery Supply Manager, Midwest Co-op Network

Step-by-Step: How an Egg Gets to Your Table (and Where It Can Get Stuck)

Understanding the journey of an egg reveals multiple vulnerability points:

- Hatching: Fertilized eggs incubate for 21 days before chicks hatch.

- Rearing: Pullets (young hens) take 16–20 weeks to mature into laying hens.

- Laying: Hens produce eggs daily, collected mechanically or manually.

- Processing: Eggs are washed, candled (checked for defects), graded, and packed.

- Distribution: Refrigerated trucks deliver to warehouses and stores.

- Retail: Stocked on shelves with a typical 30-day shelf life.

A breakdown at any stage—such as a hatchery losing a batch to disease or a processing plant shutting down for cleaning—halts the flow downstream. Because each step depends on the previous one, the system lacks redundancy. There’s no “backup” pipeline for eggs.

Mini Case Study: The 2022 Holiday Egg Crisis

In late November 2022, major U.S. retailers like Walmart and Kroger reported nationwide egg shortages just before Thanksgiving. Despite no overall decline in chicken numbers, many stores limited purchases to two cartons per customer.

The root cause was multifaceted: ongoing bird flu outbreaks had reduced laying flocks by 10–15% compared to the previous year. Simultaneously, a fire at a major Midwest egg processing facility took 1.5 million eggs per week offline. High feed costs prevented rapid flock rebuilding, and holiday demand surged 30% above average.

The result? A perfect storm. Consumers faced empty shelves, prices hit record highs, and misinformation spread about “no chickens left.” In reality, hundreds of millions of hens were still laying—but their eggs weren’t reaching stores efficiently.

Frequently Asked Questions

Does an egg shortage mean there are fewer chickens?

Not necessarily. While disease can reduce flock sizes, many shortages occur due to processing delays, transportation issues, or demand spikes—even when chicken numbers remain stable.

Can farms quickly replace lost hens?

No. It takes approximately 5 months from hatching a chick to getting its first egg. Breeding stock, feed, and housing must all align, making rapid recovery difficult.

Are organic or cage-free eggs more affected by shortages?

Often, yes. These sectors operate with smaller margins and less surplus capacity. When disruptions occur, alternative housing requirements and certification processes slow recovery.

Action Checklist: How Consumers Can Navigate Egg Shortages

- Monitor local news for bird flu alerts in poultry regions.

- Avoid bulk-buying unless absolutely necessary—help prevent artificial shortages.

- Consider frozen or liquid egg products as alternatives during shortages.

- Support local farms directly; they may have better stock during retail gaps.

- Check expiration dates carefully—higher prices don’t always mean fresher eggs.

- Use egg substitutes in baking when possible (e.g., applesauce, flaxseed).

Conclusion

An egg shortage without a visible chicken shortage may seem illogical, but it reflects the fragility of modern food systems. Chickens may still be alive and laying, but disease, economics, logistics, and human behavior collectively determine whether those eggs end up in your refrigerator.

Understanding these dynamics empowers consumers to make smarter choices—avoiding panic buys, supporting resilient suppliers, and adapting when supplies tighten. The next time you see bare shelves, remember: it’s not about how many chickens there are, but how smoothly the entire system functions from farm to table.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?