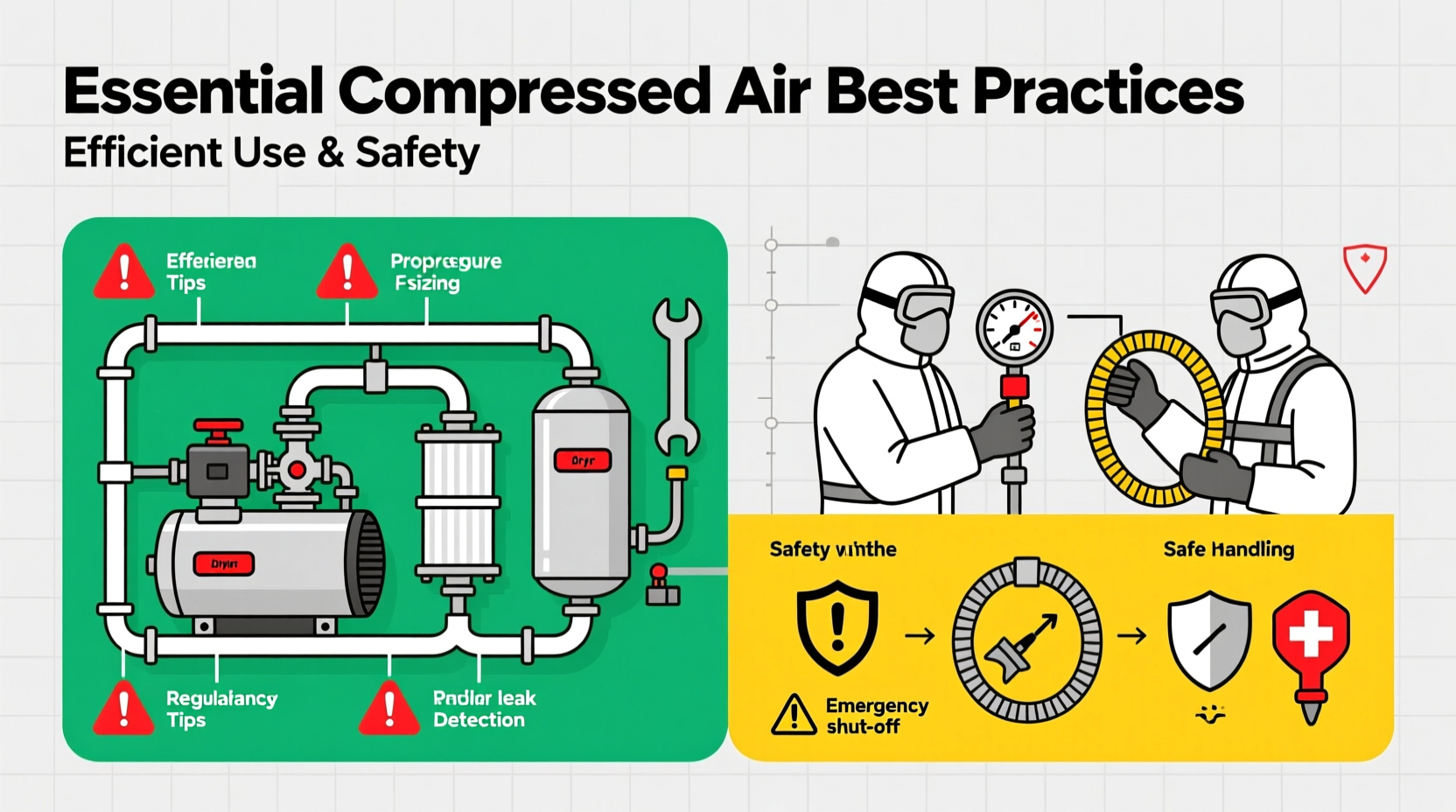

Compressed air is a critical utility across manufacturing, automotive, pharmaceutical, and food processing industries. Often referred to as the \"fourth utility\" after electricity, water, and gas, it powers tools, drives automation, and supports clean production processes. However, inefficient use or poor maintenance can lead to energy waste, equipment failure, and serious safety hazards. Implementing best practices ensures reliable performance, reduces operational costs, and protects personnel.

1. Optimize System Design and Layout

An efficiently designed compressed air system starts with proper planning. Poor layout—such as undersized piping, long distribution runs, or sharp bends—can create pressure drops that reduce tool performance and increase energy consumption. A well-designed network minimizes friction losses and delivers consistent pressure where needed.

Key considerations include:

- Using appropriately sized piping (larger diameter pipes reduce pressure drop)

- Designing looped distribution systems instead of dead-end lines

- Locating compressors close to high-demand areas when possible

- Installing isolation valves for maintenance without full shutdowns

2. Maintain Air Quality with Proper Filtration and Drying

Contaminants like moisture, oil, and particulates degrade pneumatic equipment and compromise product quality, especially in sensitive applications such as medical device manufacturing or painting operations. Moisture causes rust in tanks and lines; oil contaminates end products; dust clogs valves and seals.

To ensure clean, dry air:

- Install coalescing filters at key points to remove oil and water aerosols.

- Use desiccant or refrigerated dryers based on dew point requirements.

- Replace filter elements according to manufacturer recommendations—or sooner in dirty environments.

- Drain condensate automatically to prevent accumulation in receivers and traps.

“Over 70% of compressed air system failures are linked to contamination. Regular filtration isn’t optional—it’s foundational.” — James Langley, Industrial Maintenance Engineer

3. Eliminate Leaks and Unnecessary Usage

Leakage is one of the most significant sources of energy waste in compressed air systems. The U.S. Department of Energy estimates that an average plant loses 25–30% of its compressed air to leaks. A single 1/8-inch orifice can cost over $2,500 annually in wasted energy at standard operating pressures.

Conduct regular leak audits using ultrasonic detectors during non-production hours. Mark identified leaks and prioritize repairs by size and location.

| Orifice Size (inches) | Flow Rate (cfm) | Annual Cost @ $0.10/kWh |

|---|---|---|

| 1/16\" | 3.5 | $800 |

| 1/8\" | 15 | $2,600 |

| 1/4\" | 60 | $10,500 |

In addition to fixing leaks, eliminate wasteful practices such as open blowing for cleaning. Replace with engineered nozzles that use 80% less air while improving effectiveness.

4. Implement Preventive Maintenance Routines

Preventive maintenance extends equipment life, prevents unplanned downtime, and maintains efficiency. Compressors, dryers, filters, and storage tanks all require scheduled attention.

📋 **Monthly Maintenance Checklist**- Inspect belts for tension and wear

- Check sump levels and change oil if required

- Verify operation of automatic drain valves

- Test pressure relief valves

- Monitor differential pressure across filters

- Record operating hours and pressures

- Inspect intercoolers and aftercoolers for fouling

- Test motor insulation resistance

- Calibrate pressure and temperature sensors

- Inspect receiver tank internals for corrosion

- Review system logs for abnormal trends

Keep detailed records to identify patterns—rising discharge temperatures or increasing cycle times may indicate underlying issues before catastrophic failure occurs.

5. Prioritize Safety in Operation and Maintenance

Compressed air systems operate under high pressure and pose several risks if not handled properly. Stored energy in tanks, hot surfaces, rotating components, and noise exposure all demand strict safety protocols.

Key Safety Practices

- Always depressurize and lock out/tag out (LOTO) equipment before servicing.

- Never use compressed air for personal cleaning—even low-pressure air can force contaminants into skin or eyes.

- Wear appropriate PPE including safety glasses, gloves, and hearing protection.

- Ensure pressure relief valves are functional and never bypassed.

- Secure loose hoses to prevent whipping if disconnected under pressure.

“An unsecured hose once caused a fatality when it ruptured and struck a worker. Respect stored energy—it behaves unpredictably.” — OSHA Field Safety Report, Midwest Region

Mini Case Study: Reducing Waste at Precision Auto Parts Inc.

A mid-sized automotive supplier was experiencing frequent downtime due to clogged pneumatic controls and inconsistent tool performance. An energy audit revealed 38% of generated air was lost to leaks, primarily from aging couplings and threaded connections.

The company implemented a quarterly leak detection program using ultrasonic sensors, replaced faulty fittings with quick-connects rated for continuous duty, and installed auto-drains on all filters and receivers. Within six months, system pressure stabilized, energy costs dropped by 22%, and unplanned maintenance events decreased by half.

The success prompted management to train two technicians as certified compressed air auditors, embedding efficiency into ongoing operations rather than treating it as a one-time fix.

Step-by-Step Guide to Conducting a Basic Compressed Air Audit

- Plan the audit: Schedule during off-shifts to capture baseline usage without interference.

- Gather tools: Ultrasonic leak detector, pressure gauge, flow meter, log sheet.

- Walk the system: Start at the compressor room and follow the distribution path.

- Listen for leaks: Move the detector slowly near joints, valves, drains, and hoses.

- Mark and quantify: Tag each leak and estimate flow loss using standard charts.

- Calculate cost: Multiply total estimated leakage (cfm) by local energy rate and annual runtime.

- Prioritize repairs: Fix large leaks first, then address clusters in accessible areas.

- Re-audit quarterly: Track progress and maintain momentum.

Frequently Asked Questions

How often should compressed air filters be changed?

Most manufacturers recommend replacing filter elements every 2,000 operating hours or annually, whichever comes first. In dirty or humid environments, inspection every 500 hours is advisable. Monitor differential pressure—if it exceeds 5 psi, replace the element even if time hasn't elapsed.

Is it safe to use compressed air to blow off clothing or skin?

No. OSHA prohibits using compressed air greater than 30 psi for cleaning the body, even with personal protective equipment. Air can penetrate the skin or eyes, causing embolisms or permanent injury. Use vacuums or brushes instead.

What is the ideal pressure for most compressed air systems?

Most industrial applications operate efficiently between 90–110 psi. Running higher than necessary increases stress on components and energy use. Set regulators at the point of use to match tool requirements—not system-wide pressure.

Conclusion: Efficiency and Safety Go Hand in Hand

Efficient and safe compressed air use isn’t achieved through isolated fixes but through consistent, informed practices. From thoughtful system design to vigilant maintenance and proactive safety culture, every decision impacts reliability, cost, and workplace well-being. These best practices are not just technical guidelines—they’re investments in operational excellence.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?