Fountain pens offer a uniquely satisfying writing experience—smooth ink flow, expressive line variation, and timeless elegance. Yet even the finest pens can develop problems over time. Ink skips, leaks, or refuses to start altogether. These frustrations are common, but rarely permanent. With a few essential techniques and an understanding of how fountain pens work, most issues can be diagnosed and resolved at home. This guide equips you with the knowledge to troubleshoot confidently and keep your pen performing flawlessly.

Understanding Fountain Pen Mechanics

A fountain pen relies on a delicate balance between gravity, capillary action, and air pressure. Ink flows from the reservoir through a feed system to the nib, where it meets the paper. The tines of the nib split slightly to allow controlled ink delivery, while the feed regulates this flow using internal channels and fins. Any disruption—dried ink, misaligned tines, incompatible ink, or poor storage—can interrupt performance.

Before attempting repairs, identify the core components involved:

- Nib: The metal tip that contacts the paper; determines line width and writing feel.

- Feed: The plastic or ebonite component beneath the nib that controls ink flow.

- Section: The grip area housing the nib and feed.

- Reservoir: The ink source, whether cartridge, converter, or piston-filler.

Most issues stem from blockages, alignment errors, or improper maintenance. Recognizing symptoms early prevents minor glitches from becoming major failures.

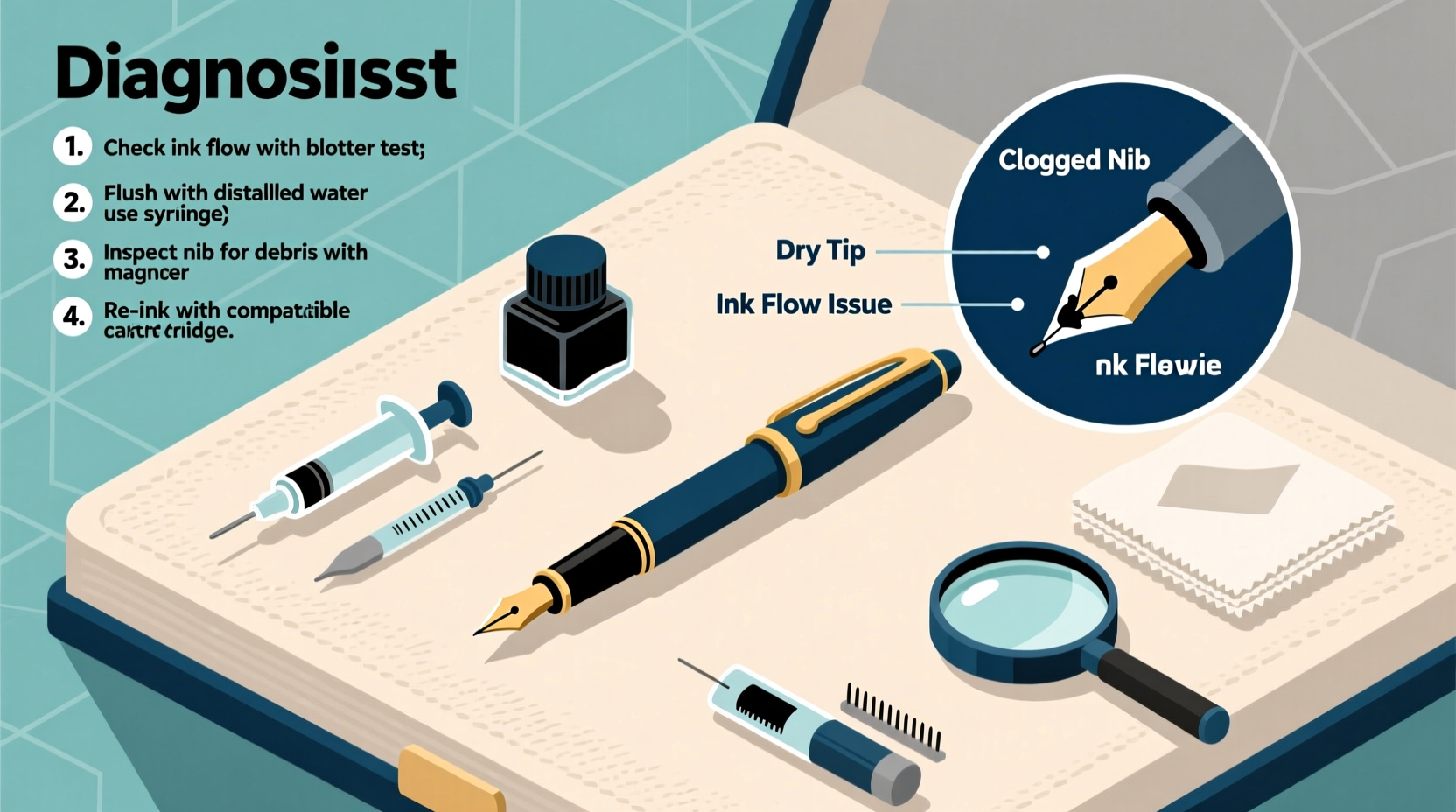

Common Issues and How to Diagnose Them

Each malfunction presents distinct clues. Accurate diagnosis is half the solution.

Ink Flow Problems: Skipping, Hard Starting, or Railroading

If your pen starts inconsistently or leaves gaps in lines (skipping), the issue may be clogged feed channels or dried ink in the nib slit. “Railroading” occurs when ink flows only along the edges of the tines, leaving a dry center—often due to overly viscous ink or insufficient wetting of the feed.

Leaking or Blobs of Ink

Leaks typically originate from a poor seal between the section and barrel, overfilled converters, or temperature/pressure changes. If ink pools around the nib after writing, check for feed saturation or cracked components.

Broad or Faint Lines

A sudden change in line width may indicate misaligned nib tines. If the tines have spread apart, ink floods the page. Conversely, if they’ve pinched together, flow diminishes. Use a loupe to inspect alignment under magnification.

Dry Writing or No Ink at All

This suggests complete blockage, airlocks in piston fillers, or depleted ink supply. Verify ink level first. If present, suspect dried residue in the feed or nib slit.

“Over 70% of fountain pen issues I see in repair shops are due to neglected cleaning or using non-pen-safe inks.” — Daniel Reyes, Master Pen Technician, Inkwell Restoration Co.

Step-by-Step Guide to Cleaning and Unclogging

Cleaning is the most effective remedy for most problems. Follow this methodical approach:

- Disassemble the pen: Remove the nib unit (nib and feed) from the section. For eyedropper pens, empty the ink first.

- Rinse under lukewarm water: Hold the nib and feed under running tap water until the outflow runs clear. Avoid hot water, which can warp ebonite feeds.

- Soak in distilled water: Submerge the nib and feed in a cup of distilled water for 12–24 hours. Change water if it becomes cloudy.

- Flush the reservoir: For converters or piston mechanisms, draw and expel water repeatedly to dislodge residue.

- Use a mild solution (if needed):strong> For stubborn clogs, soak in a 1:10 solution of ammonia and water for no more than 30 minutes. Rinse thoroughly afterward.

- Final rinse and dry: Flush with distilled water to remove any chemical traces. Let parts air-dry overnight before reassembly.

For vintage pens or those with hard rubber feeds, avoid ammonia entirely—use only distilled water or a weak vinegar solution.

Troubleshooting Table: Symptoms, Causes, and Fixes

| Symptom | Likely Cause | Recommended Fix |

|---|---|---|

| Skipping or hard starting | Dried ink, clogged feed, dirty nib | Flush with water; soak nib/feed |

| Leaking from section | Poor seal, overfilled converter | Check O-rings; refill converter correctly |

| Railroading (double line) | Ink too thick, feed drying out | Switch to free-flowing ink; clean feed |

| No ink flow | Airlock, clog, dried feed | Disassemble and flush; prime feed |

| Nib scratches paper | Tines misaligned, burr on tip | Gently realign tines; polish tip if needed |

Mini Case Study: Reviving a Dormant Pen

Sarah inherited her grandfather’s Parker 51, untouched for over 20 years. The pen wouldn’t write despite fresh ink. Initial inspection showed no visible damage, but ink didn’t reach the nib. She disassembled the pen, removed the hooded nib and feed, and soaked them in distilled water for two days, changing the water three times. After reassembly, the pen still wrote faintly. She then flushed the entire system with a syringe, gently forcing water through the feed channels. On the third flush, ink began flowing smoothly. The pen now writes like new—proof that patience and proper cleaning restore even long-dormant instruments.

Preventative Maintenance Checklist

To avoid recurring issues, follow this monthly routine:

- ✔ Clean the nib and feed by rinsing under lukewarm water

- ✔ Flush the ink reservoir, especially when changing inks

- ✔ Inspect nib tines for alignment using a magnifier

- ✔ Check for cracks or wear in the section or feed

- ✔ Store pens with nibs pointing upward to prevent leakage

- ✔ Use pH-neutral, lubricated inks designed for fountain pens

When to Seek Professional Help

Some problems exceed DIY fixes. Consider professional restoration if:

- The nib is bent or cracked.

- There’s persistent air leakage in piston mechanisms.

- The feed is split or warped.

- You suspect internal corrosion in vintage models.

Experts possess ultrasonic cleaners, precision tools, and experience with rare materials. Attempting to bend a nib without proper tools can worsen the issue.

FAQ

How often should I clean my fountain pen?

At minimum, clean every 4–6 weeks or whenever switching inks. Daily users benefit from a quick rinse weekly. Regular cleaning prevents buildup and ensures consistent performance.

Can I use tap water to clean my pen?

Tap water is acceptable for initial rinsing, but prolonged soaking should use distilled water. Minerals in tap water can leave deposits that affect ink flow over time.

Why does my pen write well at first, then stop?

This often indicates an air-pressure imbalance. As ink flows out, air must enter the reservoir to replace it. A blocked breather hole or tight cap seal can disrupt this cycle, causing premature cutoff.

Conclusion: Write with Confidence

Fountain pens reward care with decades of reliable service. Most common issues are not signs of failure, but calls for attention. By learning to diagnose symptoms, perform thorough cleanings, and maintain your tools, you preserve both function and heritage. Whether you use a modern Lamy or a vintage Sheaffer, the principles remain the same: cleanliness, compatibility, and consistency. Don’t let a dry nib or leaky joint discourage you. With the right knowledge, every pen can return to its best self.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?