Woodworking is both an art and a craft, where the quality of your final piece depends as much on your skill as it does on the materials and tools you use. Whether you're crafting a simple bookshelf or an intricate dining table, selecting the right wood species, fasteners, finishes, and tools can make the difference between a project that lasts decades and one that fails prematurely. This guide breaks down the essential materials and tools every woodworker should understand, with practical insights to help you make informed decisions.

Understanding Wood Types: Hardwood vs. Softwood

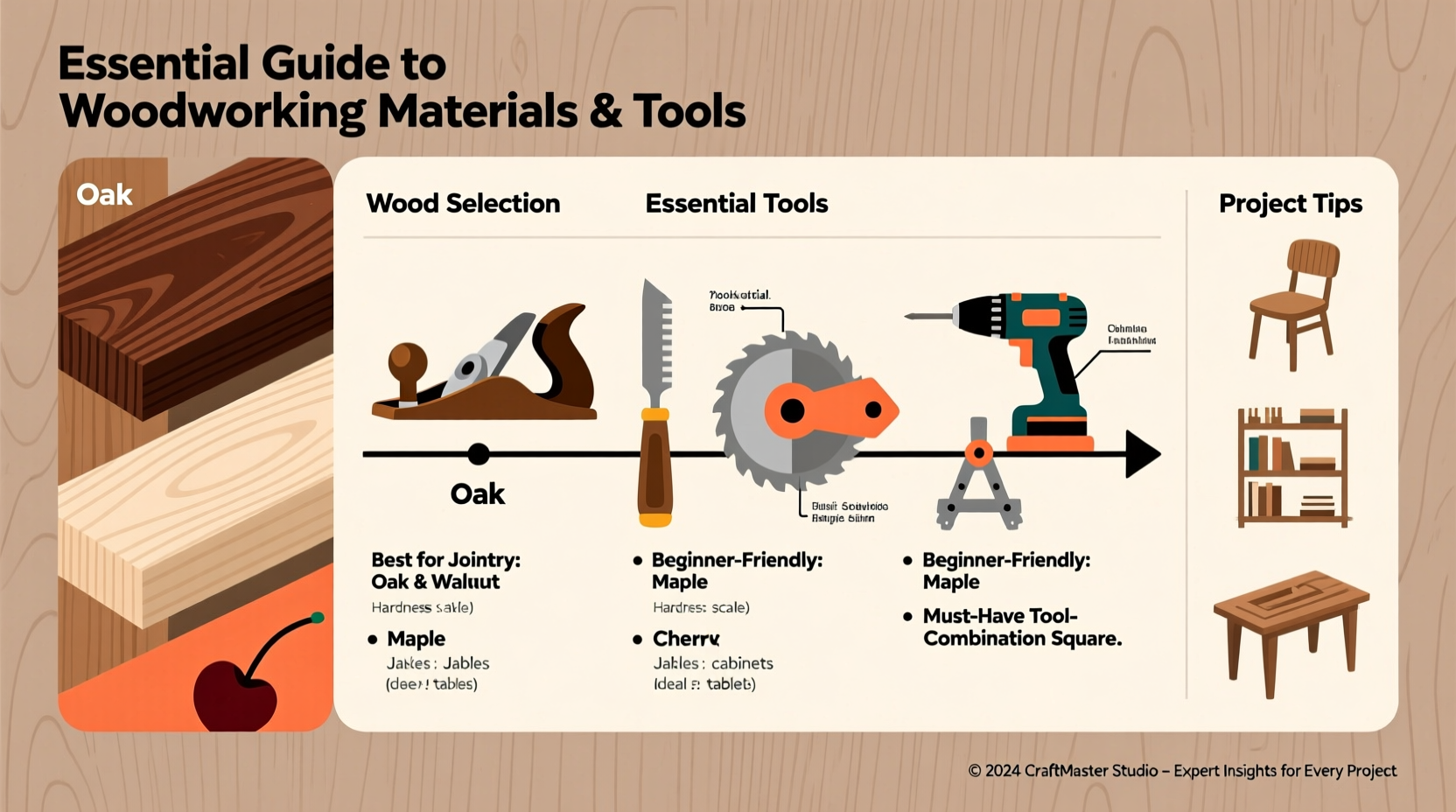

The foundation of any woodworking project is the wood itself. The two main categories—hardwood and softwood—are often misunderstood. Hardwoods come from deciduous trees (like oak, maple, and walnut) and are typically denser, more durable, and ideal for furniture and cabinetry. Softwoods, such as pine, cedar, and fir, come from coniferous trees and are generally easier to work with, making them suitable for framing, shelving, and beginner projects.

Each type has its advantages:

- Hardwoods: Offer superior strength, grain beauty, and longevity. They’re more expensive but worth the investment for high-end pieces.

- Softwoods: More affordable and readily available. Great for practice, prototypes, or outdoor structures when properly treated.

Best Wood Choices by Project Type

| Project Type | Recommended Wood | Why It Works |

|---|---|---|

| Furniture (tables, chairs) | Walnut, Cherry, White Oak | Dense grain, attractive finish, excellent durability |

| Cabinetry | Maple, Birch Plywood | Smooth surface, resists wear, easy to paint or stain |

| Outdoor Structures | Cedar, Redwood, Pressure-Treated Pine | Natural rot resistance or chemical protection against moisture |

| Beginner Projects | Pine, Poplar | Inexpensive, easy to cut and shape, forgiving for mistakes |

Essential Tools Every Woodworker Needs

No matter the scale of your workshop, certain tools are non-negotiable for precision, safety, and efficiency. Start with these core items before expanding into specialty equipment.

- Circular Saw or Track Saw: Ideal for breaking down sheet goods like plywood. A track saw offers cleaner, straighter cuts.

- Table Saw: The centerpiece of most workshops. Essential for ripping boards to width with accuracy.

- Router: Used for edge profiling, dadoes, and joinery. A plunge base adds versatility.

- Orbital Sander: Speeds up finishing work while minimizing swirl marks compared to hand sanding.

- Clamps (Bar, Pipe, and Quick-Grip): Crucial for holding joints during glue-up. Invest in a variety of sizes.

- Measuring and Marking Tools: A reliable tape measure, combination square, and marking knife ensure precision.

“Your tools are only as good as your ability to maintain them. A sharp blade and calibrated saw will outperform an expensive but neglected machine.” — Daniel Reeves, Master Cabinetmaker

Power vs. Hand Tools: Finding the Right Balance

While power tools dominate modern workshops, hand tools offer control, quiet operation, and a deeper connection to the craft. For example, a well-tuned hand plane can achieve a glass-smooth surface without tear-out—a challenge even for some routers.

Consider this balanced approach:

- Use power tools for rough dimensioning and repetitive tasks.

- Switch to hand tools for fine-tuning, fitting joints, and detailed shaping.

Choosing the Right Fasteners and Adhesives

Joinery defines the structural integrity of your work. While screws and nails have their place, traditional methods like dovetails and mortise-and-tenon joints offer unmatched strength and aesthetics. However, adhesives play a critical role in almost every project.

Common wood glues include:

- PVA (Yellow Glue): The standard for most indoor projects. Strong, easy to clean, and dries clear.

- Waterproof Glue (e.g., Titebond III): Ideal for outdoor furniture or areas exposed to moisture.

- Epoxy: Fills gaps and bonds dissimilar materials. Useful for repairs or laminating.

Screws and dowels should complement—not replace—glue joints. Over-reliance on mechanical fasteners can weaken wood fibers and create stress points.

Real Example: Building a Solid Oak Coffee Table

A woodworker in Portland built a live-edge oak coffee table using PVA glue for the slab seams and pocket screws only to hold the aprons during clamping. After the glue cured, the screws were removed. The result? A seamless top with no visible hardware and joints stronger than the surrounding wood. This approach combined the reliability of glue with the convenience of temporary fasteners—demonstrating how thoughtful material choices enhance both form and function.

Finishes That Protect and Enhance

A finish isn’t just cosmetic—it seals the wood against moisture, UV damage, and daily wear. The right choice depends on the project’s use and desired look.

| Finish Type | Best For | Drying Time | Durability |

|---|---|---|---|

| Oil-Based Polyurethane | Furniture, floors | 6–8 hours | ★★★★☆ |

| Water-Based Polyurethane | Painted or light woods | 2–4 hours | ★★★☆☆ |

| Wipe-On Oil (e.g., Watco) | Handrails, cutting boards | 12–24 hours | ★★☆☆☆ |

| Lacquer (spray or brushed) | High-gloss cabinets | 15–30 minutes | ★★★★★ |

Apply finishes in thin, even coats. Sand lightly between layers with 220-grit paper for a professional result. Always test your finish on scrap wood first to check color and sheen.

Checklist: Setting Up Your Workshop Toolkit

Before starting your next project, ensure you have the essentials:

- ✅ Quality measuring tape and combination square

- ✅ Sharp chisels and honing guide

- ✅ Benchtop or portable planer

- ✅ Set of drill bits (brad point for wood)

- ✅ Dust collection system or shop vacuum

- ✅ Safety gear: goggles, hearing protection, respirator

- ✅ Assorted clamps (at least 8 total in various lengths)

- ✅ Sharpening stones or system (1000/6000 grit)

Frequently Asked Questions

Can I use construction-grade lumber for furniture?

Yes, but with caution. Construction pine often contains knots and warps. Select the straightest pieces, joint and plane them carefully, and consider staining or painting to hide imperfections. For visible areas, hardwood is preferable.

What’s the most versatile saw for a small shop?

A combination of a table saw and a track saw covers most needs. The table saw excels at rip cuts, while the track saw handles crosscuts and sheet goods with precision and minimal space.

How do I prevent tear-out when cutting plywood?

Use a blade with 80 or more teeth, apply painter’s tape along the cut line, and support the sheet fully on both sides. Cutting with the “good” side down also helps if using a table saw.

Conclusion: Build with Confidence

Great woodworking begins long before the first cut—with smart choices in materials and tools. Understanding the characteristics of different woods, investing in reliable equipment, and mastering fundamental techniques empower you to create pieces that are not only beautiful but built to last. Don’t rush the process; let each decision, from glue selection to sandpaper grit, reflect your commitment to craftsmanship.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?