Whether you're pouring a patio, building a foundation, or setting fence posts, getting the concrete quantity right is critical. Too little, and you risk delays or weak joints from cold pours. Too much, and you're wasting time, labor, and money. Unlike other materials, unused concrete can’t be returned or stored. Precision matters. This guide walks through the exact process of calculating concrete volume, adjusting for real-world conditions, and avoiding common mistakes that lead to costly errors.

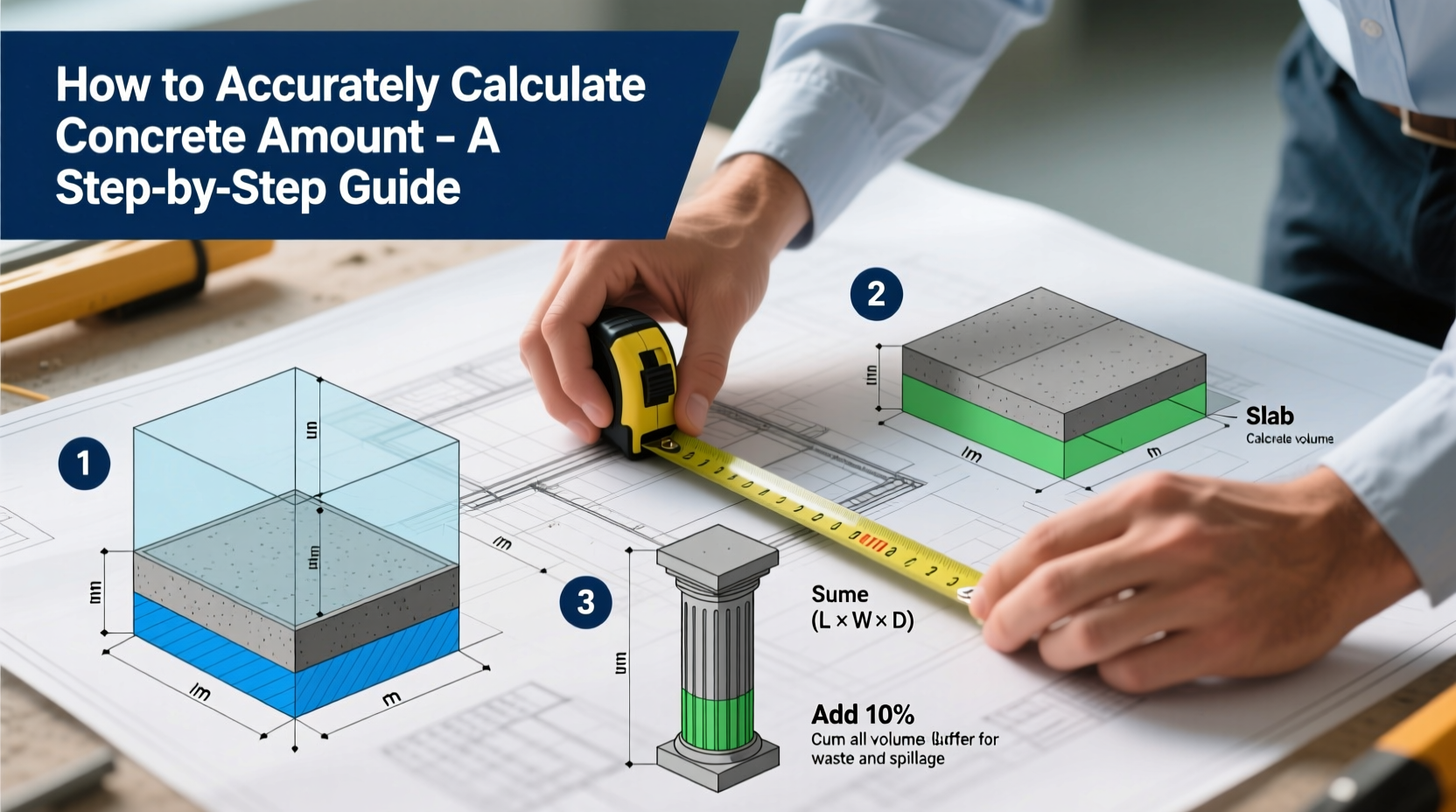

Step 1: Understand Concrete Volume Basics

Concrete is measured in cubic units—typically cubic feet, cubic yards, or cubic meters. In the U.S., suppliers deliver ready-mix concrete in cubic yards. One cubic yard equals 27 cubic feet (3 ft × 3 ft × 3 ft). The first step is determining the volume of space your pour will occupy.

The basic formula for volume is:

Volume = Length × Width × Height (or Depth)

This applies to any rectangular slab, footing, or wall. For example, a 10-foot by 12-foot patio with a depth of 4 inches requires conversion of all measurements to the same unit—preferably feet.

Convert 4 inches to feet: 4 ÷ 12 = 0.333 feet.

Volume = 10 × 12 × 0.333 = 39.96 cubic feet.

To convert to cubic yards: divide by 27.

39.96 ÷ 27 ≈ 1.48 cubic yards.

Step 2: Adjust for Complex Shapes and Openings

Not all projects are perfect rectangles. Footings may have columns, driveways might include curves, and foundations often contain openings for doors and windows. Break irregular shapes into manageable geometric sections.

For circular areas like piers or footings, use the cylinder volume formula:

Volume = π × r² × h

Where π ≈ 3.14, r is radius in feet, and h is height (depth).

Example: A round pier with a 12-inch diameter (1 ft) and 4-foot depth:

Radius = 0.5 ft

Volume = 3.14 × (0.5)² × 4 = 3.14 × 0.25 × 4 = 3.14 cubic feet per pier.

Divide by 27 to get ≈ 0.116 cubic yards per pier.

If you’re pouring multiple piers, multiply the single-unit volume by the number of units. Then add this to slab volume if applicable.

For cutouts—like doorways or utility chases—calculate their volume and subtract from the total. A 3-foot by 7-foot doorway in a 6-inch-thick wall (0.5 ft):

Volume = 3 × 7 × 0.5 = 10.5 cubic feet.

Subtract this from the gross wall volume.

Step 3: Account for Waste and Overage

No pour is perfectly efficient. Some concrete is lost to spillage, uneven subgrade, form leakage, or minor miscalibrations in the mix truck. Industry standards recommend adding a 5–10% overage to your calculated volume.

Using the earlier patio example (1.48 cubic yards):

10% overage = 1.48 × 0.10 = 0.148

Total ordered = 1.48 + 0.148 = 1.628 cubic yards → Round up to 1.75 cubic yards.

Always round up to the nearest quarter-yard increment, as suppliers typically deliver in 0.25-yard increments.

“Underestimating concrete leads to rushed decisions on-site. I always advise clients to order 10% extra—it’s cheaper than an emergency second load.” — Mark Reynolds, Structural Foreman with 22 years in residential construction

Step 4: Use a Calculation Checklist

To avoid missed steps, follow this practical checklist before placing your concrete order:

- Measure length, width, and depth of each section in feet

- Convert inches to decimal feet (e.g., 4\" = 0.333')

- Calculate volume in cubic feet per section

- Sum all volumes

- Convert total to cubic yards (divide by 27)

- Subtract volumes for openings or voids

- Add 5–10% waste factor

- Round up to nearest 0.25 cubic yard

- Confirm delivery access and schedule with supplier

Step 5: Real-World Example – Building a Garage Slab

Consider a homeowner building a 24' × 24' detached garage with a 6-inch-thick slab. There are no internal walls or columns, but the perimeter includes a 12\" wide by 12\" deep footer around the edge.

Slab calculation:

Depth = 6\" = 0.5'

Volume = 24 × 24 × 0.5 = 288 cubic feet

Footer calculation:

The footer runs along the perimeter: 24' + 24' + 24' + 24' = 96 linear feet

Cross-sectional area = 1' × 1' = 1 sq ft

Volume = 96 × 1 = 96 cubic feet

Total volume:

288 + 96 = 384 cubic feet

384 ÷ 27 ≈ 14.22 cubic yards

Add 10% waste:

14.22 × 1.10 = 15.64 cubic yards → Round up to 15.75 cubic yards

The final order should be 15.75 cubic yards. Ordering only 14 would risk falling short during placement, especially if the subgrade isn’t perfectly compacted.

Common Mistakes and How to Avoid Them

| Mistake | Why It’s Problematic | Solution |

|---|---|---|

| Using inches without converting | Leads to massive overestimation (e.g., treating 4\" as 4') | Always convert inches to decimal feet before multiplying |

| Ignoring waste factor | Risk of running out mid-pour; cold joints reduce strength | Add 5–10% buffer depending on complexity |

| Forgetting footings or thickened edges | Foundation instability due to insufficient material | Break project into zones and measure each separately |

| Ordering exact calculated volume | No room for adjustment; trucks don’t partial-discharge well | Round up to next 0.25-yard increment |

Frequently Asked Questions

How accurate do my measurements need to be?

Extremely accurate. A 1-inch error in depth over a large slab can mean hundreds of pounds of excess or missing concrete. Use a laser level and tape measure twice. For large jobs, consider hiring a surveyor to verify elevation and dimensions.

Can I mix bagged concrete instead of ordering a truck?

Yes, for small projects under 1 cubic yard. Each 80-pound bag yields about 0.022 cubic feet. Divide total cubic feet needed by 0.022 to find the number of bags. However, mixing by hand is labor-intensive and inconsistent. For anything over 30 bags, ready-mix is more economical and reliable.

What happens if I order too much concrete?

Unused concrete hardens quickly and disposal costs money. Some suppliers charge a “short load” fee for small orders, but they rarely take returns. If you consistently over-order, consider optimizing future designs with thicker vapor barriers or adjustable forms to absorb slight variances.

Final Tips for Success

Planning a concrete pour is more than math—it’s logistics, timing, and preparation. Even with perfect calculations, poor site readiness can ruin a job. Ensure forms are braced, rebar is placed, and tools are on-site before the truck arrives. Communicate clearly with the supplier about access, pour speed, and finish requirements.

Use a wheelbarrow and stopwatch to estimate placement speed: time how long it takes to move one cubic yard across the site. This helps determine how many workers you’ll need to keep up with the truck.

“The difference between a professional pour and an amateur one isn’t just the finish—it’s the planning. Accurate volume calculation is where professionalism starts.” — Lila Nguyen, Civil Engineering Consultant

Take Action Today

Grab your tape measure, sketch your project layout, and start calculating. Whether you're laying a walkway or anchoring a shed, precise concrete estimation saves money, reduces stress, and ensures a durable result. Don’t guess—measure, calculate, adjust, and order with confidence. Your next project will be stronger, smoother, and more efficient because of it.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?