3D printed dinosaur toys have surged in popularity, combining modern manufacturing with nostalgic play. Whether for children’s imaginative play, educational use, or collector display, these models offer intricate detail and customization that mass-produced plastic toys often lack. However, affordability and quality don’t always go hand-in-hand. Many consumers end up overpaying for subpar prints or sacrificing durability for a lower price. The key lies in knowing where to look, what materials matter, and how to evaluate digital designs before committing to a purchase.

The good news is that with the right approach, you can acquire high-quality, durable 3D printed dinosaur toys at accessible prices. It requires understanding filament types, print resolution, design sources, and vendor reliability. This guide walks through proven strategies to help you make smart purchasing decisions—without compromising on structural integrity, safety, or visual appeal.

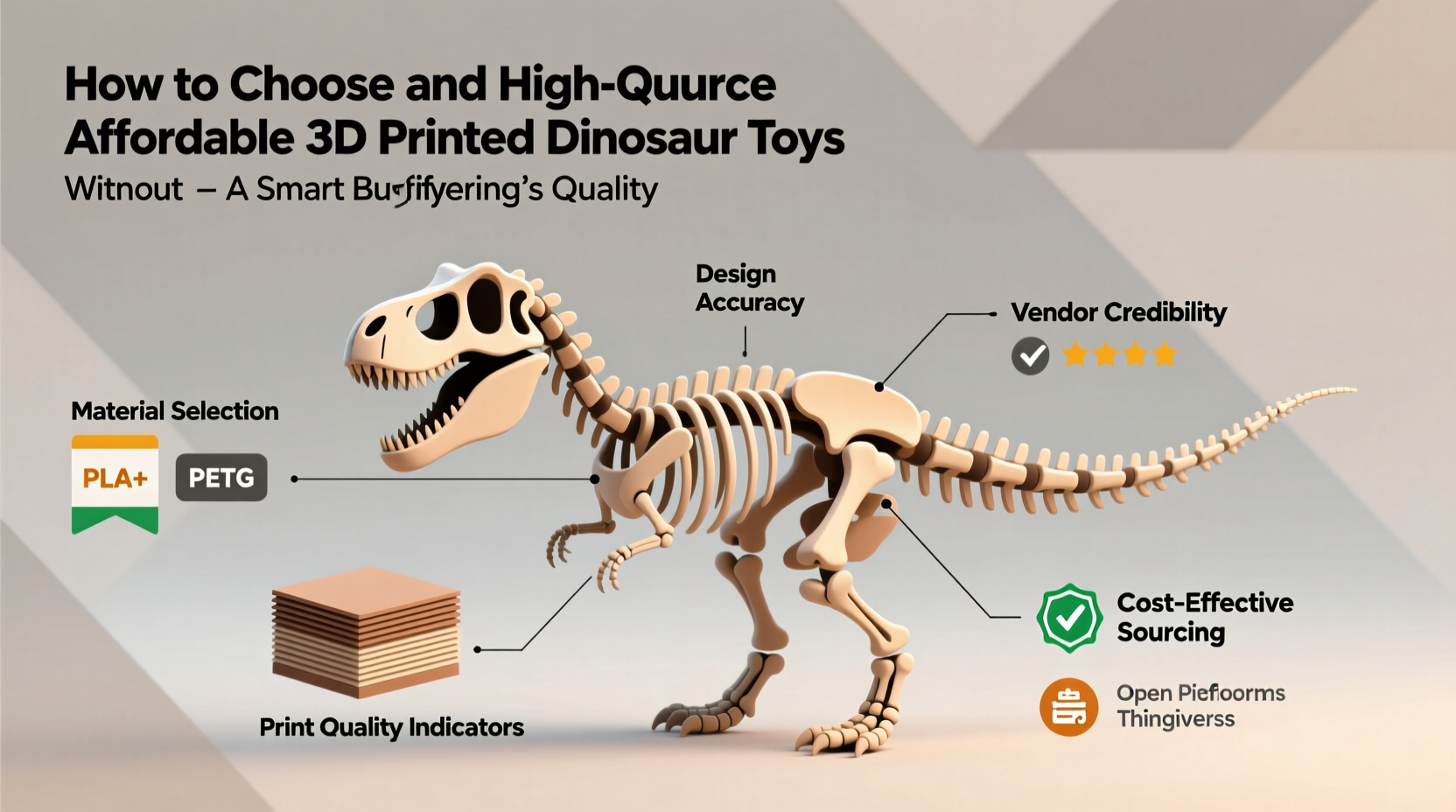

Understanding Material Quality: What Filament Works Best?

The material used in 3D printing directly impacts a toy’s durability, finish, and safety—especially important when children are involved. Not all filaments are created equal, and choosing the right one can mean the difference between a toy that lasts years and one that cracks after a week.

- PLA (Polylactic Acid): The most common choice for dinosaur toys. PLA is biodegradable, derived from cornstarch, and emits no toxic fumes during printing. It produces crisp details ideal for fine features like teeth and claws. However, it’s less heat-resistant and can warp in hot environments.

- PETG: Offers greater durability and flexibility than PLA, making it ideal for toys that will endure rough handling. It’s also more resistant to UV light and moisture, which helps prevent discoloration over time.

- TPU (Thermoplastic Polyurethane): A flexible, rubber-like material. While not typically used for entire dinosaurs, it can be incorporated into joints for poseable models. Great for “squishy” toy versions but harder to print and more expensive.

Where to Source Affordable and High-Quality Prints

You don’t need a 3D printer to enjoy custom dinosaur models. Many online platforms connect buyers with independent makers who produce small-batch, high-detail prints. Knowing where to shop—and how to assess seller credibility—is crucial for balancing cost and quality.

| Platform | Average Price Range | Pros | Cons |

|---|---|---|---|

| Thingiverse + Local Printers | $5–$15 per model | Free designs; low-cost local labor | Requires coordination; variable print quality |

| Etsy | $12–$30 | Curated quality; customer reviews; shipping included | Premium pricing for niche items |

| PrintedMiniFactory | $8–$20 | Specializes in pre-printed collectibles; consistent quality | Limited dinosaur selection |

| eBay / Facebook Marketplace | $6–$18 | Bargain deals; local pickup options | Risk of poor communication or damaged goods |

For maximum savings, consider downloading free STL files from trusted repositories like Thingiverse or Cults3D and commissioning a local maker via Facebook groups or university engineering departments. Many students or hobbyists operate printers at near-cost rates for extra income.

Step-by-Step Guide to Sourcing a High-Value Dinosaur Toy

- Define your purpose: Is this a child’s toy, classroom model, or display piece? This determines size, material, and required durability.

- Select a design platform: Browse sites like MyMiniFactory or Pinshape for vetted, high-resolution dinosaur models. Look for ones with user ratings above 4.5/5.

- Evaluate design complexity: Check layer count and overhangs. Highly detailed models may require support structures, increasing material cost and post-processing time.

- Contact local 3D printing services: Use platforms like 3D Hubs (now Protolabs Network) or community maker spaces to get quotes. Specify filament type and infill (20% is standard for toys).

- Request a sample print: If ordering in bulk, ask for a prototype. Assess edge smoothness, color consistency, and structural strength.

- Finalize and scale: Once satisfied, place your order. Consider batch discounts if buying multiple units.

“Many people assume 3D printed means expensive or fragile. In reality, a well-designed PLA print with 20% infill is both sturdy and economical.” — Dr. Lena Torres, Additive Manufacturing Researcher, University of Colorado

Checklist: Ensuring Value Without Compromising Quality

- ☐ Confirm the model file includes scaling instructions (e.g., 1:10 Jurassic Park T-Rex)

- ☐ Verify filament type matches intended use (PLA for display, PETG for active play)

- ☐ Check seller reviews—minimum 10 with photos and repeat customers

- ☐ Ask about infill density and print orientation (affects strength)

- ☐ Ensure sanding or smoothing was done to remove sharp edges

- ☐ Confirm shipping method protects fragile parts (e.g., padded compartments)

Real Example: A Teacher’s Classroom Project on a Budget

Sarah Kim, a 4th-grade science teacher in Portland, needed 24 dinosaur models for a paleontology unit. Her budget: under $200. Instead of buying prepackaged kits at $15 each, she downloaded free, anatomically accurate T-Rex and Stegosaurus models from Thingiverse. She reached out to a local college’s engineering club, offering $5 per print in exchange for student volunteer hours. The students used leftover PLA filament and printed the toys over a weekend. Sarah received all 24 models in under two weeks—each sanded smooth and painted by her students. Total cost: $120. The project not only saved money but became an interdisciplinary lesson in design, biology, and manufacturing.

Frequently Asked Questions

Are 3D printed toys safe for young children?

Yes, if made correctly. Use non-toxic PLA or PETG, ensure all parts are securely fused, and avoid small detachable pieces for children under 3. Sand down any rough edges to prevent cuts.

Can I customize the color or size of a 3D printed dinosaur?

Absolutely. Most designers allow scaling directly in slicing software. For color, specify your preference when ordering, or paint the model yourself using acrylics. Multi-color prints are possible with dual-extrusion printers but increase cost.

How do I know if a 3D model is high quality before printing?

Download a preview and inspect it in a 3D viewer like Meshmixer. Look for clean mesh geometry, no holes or overlapping faces, and appropriate wall thickness (at least 1.2mm for durability). Files labeled “optimized for FDM printing” are usually reliable.

Making Smart Choices Pays Off

Choosing affordable 3D printed dinosaur toys doesn’t mean settling for flimsy, poorly finished models. By focusing on material selection, sourcing from trustworthy creators, and leveraging community resources, you can access exceptional value. The growing accessibility of 3D printing technology has democratized custom toy production—what once required factory tooling can now be made on demand, locally, and affordably.

Whether you're outfitting a classroom, delighting a curious child, or building a personal collection, the combination of smart research and strategic sourcing ensures you get both quality and economy. Start small, test one model, and scale up as you gain confidence in your suppliers and preferred designs.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?