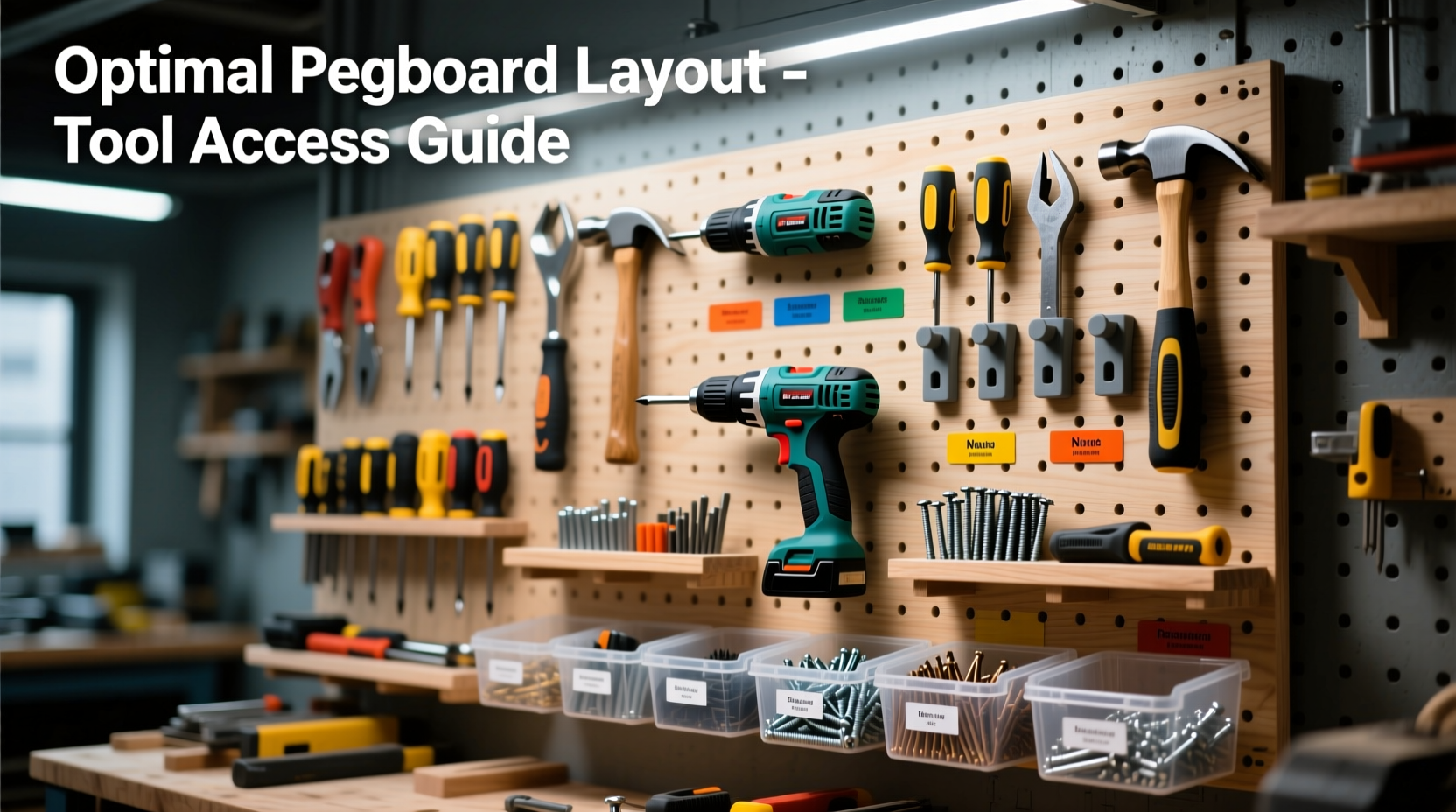

A well-organized workshop begins with smart tool storage. Among all available systems, pegboards remain one of the most versatile and accessible solutions for storing hand tools. Their adaptability allows customization based on your specific needs, but only if used correctly. Too often, pegboards become cluttered dumping grounds rather than efficient organizers. The key isn’t just hanging tools—it’s designing a system that supports workflow, visibility, and muscle memory. With thoughtful planning, you can transform your pegboard into an intuitive command center for your tools.

Assess Your Tools and Workflow

Before drilling a single hole, take inventory of your tools and how you use them. Not every tool deserves prime real estate. Group items by frequency of use: daily drivers, occasional tools, and rarely used specialty items. This hierarchy informs placement—frequently used tools should be at eye level and within easy reach, while less common ones can occupy higher or lower zones.

Also consider your dominant hand and natural movement patterns. If you're right-handed, place screwdrivers, pliers, and wrenches slightly to the right side for quicker access. Observe how you move around your workspace. Do you stand directly in front of the board? Work from the side? These habits shape optimal positioning.

Choose the Right Pegboard and Hardware

Pegboard comes in various materials—hardboard, steel, plastic—each with pros and cons. Hardboard is affordable and widely available but susceptible to moisture and warping. Steel pegboard is durable and fire-resistant but more expensive and harder to install. Plastic panels are lightweight and moisture-proof, ideal for damp garages.

Standard pegboard has 1/4-inch holes spaced 1 inch apart in a triangular grid. Compatibility with accessories is crucial. Use high-quality, load-rated hooks, bins, and brackets designed for your board type. Avoid flimsy hardware that bends under weight. For heavy tools like drills or clamps, use double-hook supports or L-brackets anchored into wall studs.

“Pegboard organization fails not because of the system, but because of poor hardware selection. Invest in sturdy, adjustable components.” — Mark Reynolds, Workshop Design Consultant

Design a Functional Layout

Effective layout follows three principles: grouping, spacing, and labeling. Group tools by function—drilling, fastening, measuring, cutting—so everything needed for a task is together. Leave adequate space between items to prevent crowding and make removal easier. Overcrowding leads to frustration and dropped tools.

Use vertical space wisely. Place heaviest tools at mid-height (waist to chest level) to reduce strain. Reserve top sections for light, infrequently used items. Bottom areas can hold larger bins or power tool accessories.

| Zone | Height Range | Recommended Tools |

|---|---|---|

| Top | Above shoulder | Spare bits, extension cords, rarely used tools |

| Primary | Eye to waist level | Hammer, screwdrivers, pliers, tape measure, utility knife |

| Lower | Below waist | Bins for small parts, sandpaper, drill cases |

Outline Tools for Instant Recognition

One of the most effective techniques is tracing each tool directly onto the pegboard. When a tool is returned, its silhouette makes misplacement obvious. Use a fine-tip permanent marker or paint pen. For shared workshops, this prevents confusion and speeds up cleanup.

Step-by-Step Guide to Installing Your Pegboard System

- Measure and mark your wall area. Choose a flat, stud-supported section near your primary workbench.

- Cut pegboard to size. Use a circular saw with a fine-tooth blade for clean edges.

- Mount support frame. Install a wooden or metal perimeter frame anchored into wall studs for stability.

- Attach pegboard. Secure with screws every 6–8 inches along the frame.

- Plan layout with temporary placement. Use removable tape or sticky notes to simulate hook positions.

- Install hooks and accessories. Start with largest items, then fill in with smaller tools.

- Trace tool outlines. Remove each tool and trace its shape next to the hook.

- Label zones if needed. Add small tags or labels for bins holding nails, screws, or drill bits.

Real-World Example: A Carpenter’s Efficient Setup

James, a residential carpenter with a home garage shop, struggled with misplaced tools slowing down his morning setup. He installed a 4x8-foot hardboard pegboard opposite his workbench. After auditing his daily toolkit, he grouped essentials: framing hammer, speed square, chalk line, and nail pouch on the central panel. Power tools like his circular saw and impact driver hung just off-center with their battery chargers nearby. Smaller items—bit sets, levels, pencils—went into labeled bins below.

The change cut his tool retrieval time by nearly 70%. More importantly, cleanup became automatic. His crew now returns tools to their outlined spots without prompting. “It’s not just about neatness,” James says. “It’s about starting each job faster and ending it without hunting for a lost tape measure.”

Common Mistakes to Avoid

- Overloading hooks: One hook should carry one primary tool. Stacking causes imbalance and wear.

- Ignoring weight limits: Heavy tools need reinforced mounting or alternative storage.

- Poor lighting: Shadows obscure outlines. Install LED strip lights above or behind the board.

- No maintenance plan: Dust and debris accumulate. Wipe down the board quarterly.

- Forgetting future needs: Leave 15–20% of the board empty for new tools or reorganization.

Frequently Asked Questions

Can I paint my pegboard?

Yes. Painting improves appearance and protects against moisture. Use primer first, then spray paint in light colors for better contrast. Avoid thick coats that clog holes. Let dry completely before installing hardware.

How do I keep small parts organized on a pegboard?

Use modular bins or mesh baskets designed for pegboard grids. Label each compartment clearly—for example, “#8 Screws,” “Drill Bits 1/8–1/4,” or “Nails – 2””. Magnetic strips can also hold tiny metal items like washers or brackets.

Is pegboard safe in a humid garage?

Standard hardboard absorbs moisture and sags over time. In damp environments, use PVC-coated pegboard or marine-grade panels. Alternatively, seal both sides with waterproof varnish before installation.

Checklist: Optimizing Your Pegboard Organization

- ✅ Take inventory of all hand tools

- ✅ Sort tools by frequency and function

- ✅ Measure wall space and choose appropriate pegboard size

- ✅ Select durable, weight-appropriate hooks and bins

- ✅ Mount board securely into wall studs

- ✅ Arrange tools in ergonomic zones

- ✅ Trace outlines for visual clarity

- ✅ Install supplemental lighting if needed

- ✅ Review and adjust layout monthly for 3 months

- ✅ Maintain with regular cleaning

Final Thoughts

Organizing tools on a pegboard isn’t a one-time project—it’s an ongoing refinement of your workspace efficiency. The best system evolves with your needs, adapting as your skills grow and your toolkit expands. By prioritizing accessibility, clarity, and durability, you create more than order; you build momentum. Every second saved finding a wrench is a second gained toward completing your next project.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?