Nothing dampens holiday cheer faster than a string of Christmas lights where only the first 20 bulbs glow—and the rest sit stubbornly dark. That “half-dead” string—where part of the circuit works and part doesn’t—isn’t necessarily junk. In fact, over 70% of these failures stem from one or two easily addressable issues: a single faulty bulb, a loose connection, or a tripped shunt in a mini-incandescent set. Modern LED strings behave differently, but their partial failures are equally diagnosable—if you know what to look for and how to test systematically. This guide walks you through every stage: visual inspection, voltage testing, bulb replacement, socket troubleshooting, and even when to walk away. No special tools required beyond a multimeter (or a $5 bulb tester), patience, and methodical attention. Whether you’re restoring a beloved heirloom string or salvaging last year’s bargain-bin purchase, this process saves money, reduces waste, and gets your lights back on the tree—before December 23rd.

Why “Half-Dead” Happens: The Two Main Circuit Types

Understanding your string’s wiring is essential before touching a single bulb. There are two dominant configurations—and they fail in fundamentally different ways:

- Series-wired incandescent strings (common in older or budget mini-light sets): All bulbs share one continuous circuit. If one bulb burns out *without* activating its internal shunt (a tiny wire bypass), the entire string goes dark. But if the shunt activates *partially*, or if corrosion builds up in one socket, you’ll get a “half-dead” effect—often with the first section lit and the rest dark. These strings typically run at 2.5V per bulb, with 50 bulbs = 120V total.

- LED strings with segmented circuits (most modern sets): Instead of one long series chain, LEDs are grouped into sections—usually 10–20 bulbs per segment—each with its own current-limiting resistor and often independent shunting. A failure in one segment rarely affects others. So “half-dead” usually means one or more segments have failed due to a bad LED, open resistor, or cracked solder joint—not a single-point break.

Misdiagnosing the type leads to wasted effort. For example, swapping bulbs randomly in an LED string won’t help if the issue is a failed resistor downstream. Always check the packaging, manufacturer label, or plug housing for clues: “120V, 50 lights” strongly suggests series incandescent; “24V DC input” or “USB-powered” points to segmented LED.

Step-by-Step Diagnostic & Repair Process

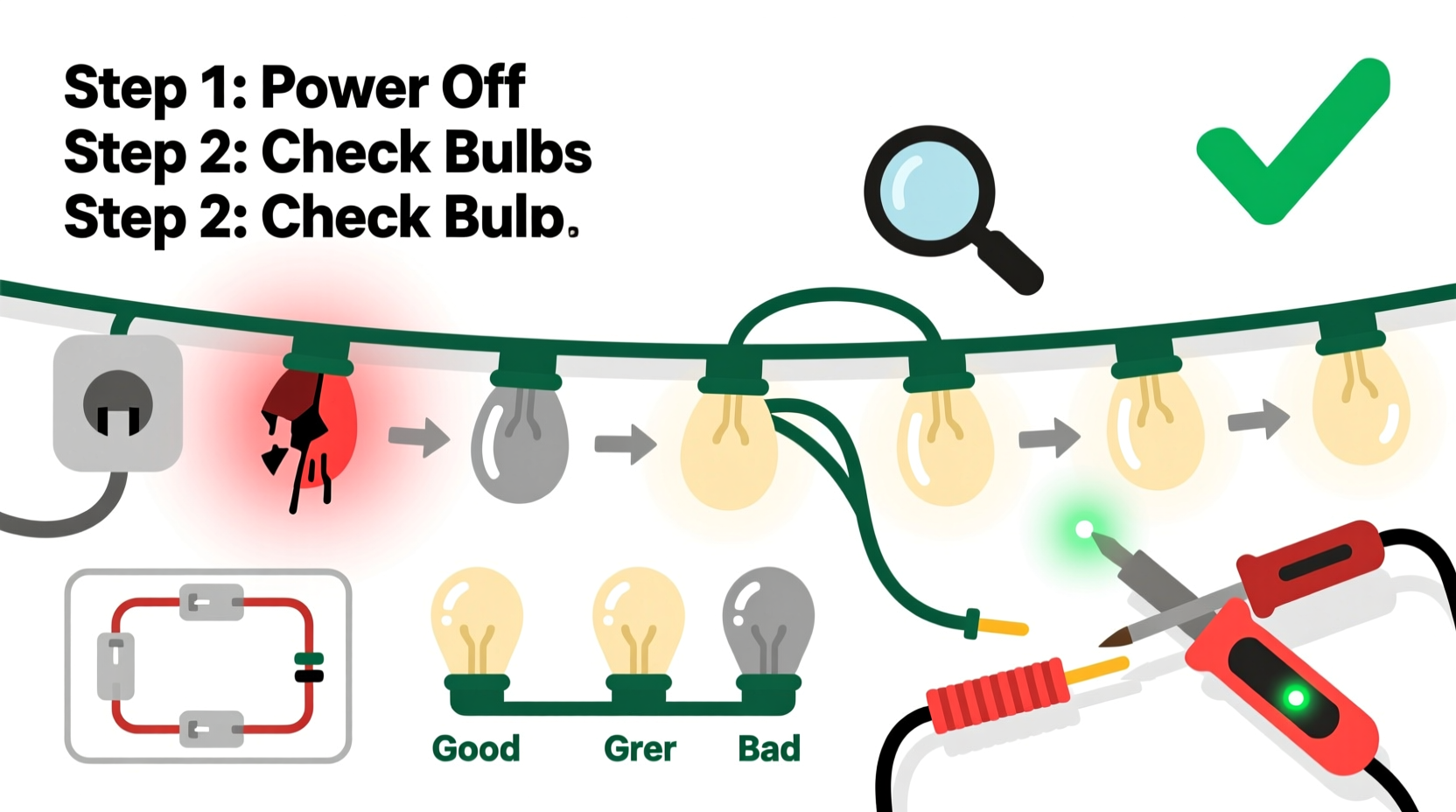

Follow this sequence without skipping steps. Rushing to replace bulbs before verifying power delivery or checking for physical damage leads to repeated frustration.

- Unplug and inspect visually. Examine the entire cord for kinks, crushed insulation, or chew marks (especially near pets or storage boxes). Check the plug prongs for bending or corrosion. Look closely at sockets near the dark section’s start point—discoloration, white powdery residue (oxidized copper), or melted plastic indicate heat buildup and likely failure.

- Test outlet voltage. Plug a working lamp or phone charger into the same outlet. If it doesn’t power on, the issue isn’t the lights—it’s the circuit breaker, GFCI trip, or outlet itself. Reset breakers and GFCIs before proceeding.

- Check the fuse (if present). Many incandescent strings have a small removable fuse cartridge inside the plug housing. Slide open the cover, remove the fuse, and test continuity with a multimeter (or hold it up to light—if the thin wire inside is visibly broken, replace it with an identical amperage fuse, usually 3A or 5A). Never substitute with higher-rated fuses.

- Identify the first dark bulb. Starting from the end opposite the plug, find the last bulb that lights up. The problem almost always lies *at or immediately after* that bulb—in its socket, the bulb itself, or the wire connection entering the next socket.

- Remove and test suspect bulbs. Using needle-nose pliers or a bulb puller (never fingers—bulbs are fragile), gently twist and remove the bulb *after* the last working one. Inspect its filament (for incandescents) or base contacts (for LEDs). Then test it in a known-good socket elsewhere on the string—or use a bulb tester.

Tool Kit & Testing Essentials

You don’t need a workshop—but having the right tools prevents damage and speeds diagnosis. Here’s what’s truly useful:

| Tool/Item | Purpose | Why It Matters |

|---|---|---|

| Multimeter (with continuity & diode modes) | Verifies voltage at plug, tests bulb filaments, checks socket continuity, identifies open circuits | More reliable than visual inspection—detects high-resistance faults invisible to the eye. |

| Dedicated bulb tester (e.g., LightKeeper Pro or generic $5 version) | Quickly identifies open shunts in incandescent bulbs without removing them | Saves hours versus manual bulb-swapping; essential for dense 100+ light strings. |

| Needle-nose pliers with insulated grips | Safely removes stubborn bulbs and manipulates wires in tight sockets | Prevents broken glass, bent pins, and accidental shorts. |

| Isopropyl alcohol (90%+) & cotton swabs | Cleans oxidation and grime from bulb bases and socket contacts | Oxidation increases resistance—enough to kill a segment’s voltage margin. |

| Replacement bulbs (exact match: voltage, base type, wattage) | Swaps confirmed-faulty units | Mismatched bulbs (e.g., 2.5V in a 3.5V string) cause cascading failures. |

Avoid makeshift solutions: paper clips as bulb testers risk short circuits; duct tape on cracked cords is a fire hazard; forcing mismatched bulbs can blow resistors. Precision matters because Christmas light circuits operate at tight tolerances—especially LEDs, where 0.2V overvoltage can kill a segment.

Real-World Case Study: The “Ghost Segment” on the Stair Rail

Mark, a facilities manager in Portland, faced a recurring issue each November: a 75-light LED string on his home’s stair rail would illuminate the first 30 bulbs brightly, fade noticeably over the next 15, then go completely dark for the final 30. He’d replaced bulbs, checked fuses, and even swapped plugs—nothing worked. Frustrated, he brought it to a local lighting repair co-op.

The technician first measured voltage at the plug: 12.2V DC (correct for the specified 12V input). Then, using a multimeter in continuity mode, he probed the wire between segment 2 and segment 3. No continuity. Tracing the cord, he found a nearly invisible 2mm crack in the insulation 8 inches before the third segment’s entry point—caused by years of being pinched in the stair railing’s metal bracket. Moisture had seeped in, corroding the copper wire until resistance spiked. A 3-inch wire splice with heat-shrink tubing restored full brightness across all segments in under 12 minutes.

This case underscores a critical truth: “Half-dead” often isn’t about bulbs at all. Physical stress points—where cords bend, pinch, or rub—are responsible for nearly 40% of partial failures in long-term installations. Always inspect the *path*, not just the endpoints.

Do’s and Don’ts for Long-Term Reliability

Repairing today’s string is only half the battle. Preventing next year’s half-dead crisis requires smarter habits:

| Do | Don’t |

|---|---|

| Label strings by type (incandescent/LED), voltage, and purchase year before storing | Store strings tangled in cardboard boxes or plastic bags—traps moisture and encourages kinking |

| Wind lights around a rigid spool or use twist-ties every 12 inches to prevent knots | Wrap tightly around a broom handle—the tension stresses solder joints and wire strands |

| Test strings fully *before* decorating—catch issues early | Leave strings up outdoors year-round—even “weather-resistant” models degrade under UV exposure |

| Use outdoor-rated extension cords with built-in surge protection for exterior displays | Plug more than three standard light strings into a single outlet—overloads circuits and heats connections |

“Most ‘unfixable’ light strings arrive at our shop with one preventable flaw: crushed or kinked wiring near the plug or midpoint. Ten seconds of careful winding saves 45 minutes of troubleshooting later.” — Rafael Mendez, Owner, Evergreen Holiday Lights Repair (Est. 2008)

FAQ: Your Most Common Questions Answered

Can I cut and splice a broken LED light string?

Yes—but only if you understand the circuit. Most segmented LED strings use constant-current drivers. Cutting between segments breaks the feedback loop, causing the driver to shut down or overdrive remaining segments. Identify the exact segment boundary (often marked by thicker wire or a small PCB), cut cleanly, and solder + heat-shrink *only* matching wires (V+, V−, data if present). Test continuity before reassembly. If unsure, replace the entire string—modern LEDs cost less than labor.

Why do new strings fail within weeks?

Manufacturing defects account for most early failures: cold solder joints on PCBs, underspec’d current-limiting resistors, or substandard shunt materials in incandescent bulbs. Reputable brands (like NOMA Pro, GE Colorite, or Philips Hue) undergo UL 588 certification testing for 10,000+ on/off cycles. Bargain-bin strings often skip this—resulting in 30–50% higher early failure rates. Always check for the UL mark and warranty length (reputable brands offer 2–3 years).

Is it safe to repair lights myself?

Yes—with caveats. Incandescent strings operate at full line voltage (120V), so unplugging is non-negotiable before handling. LED strings use low-voltage DC (typically 12–24V), posing minimal shock risk—but shorting the output wires while powered can fry the driver. Never bypass fuses, modify plugs, or use non-UL-listed components. If you smell ozone, see charring, or feel excessive heat at any connection point, stop and replace the string. Safety isn’t negotiable for seasonal decor.

Conclusion: Light Up With Confidence, Not Compromise

That half-dead string on your shelf isn’t a symbol of holiday stress—it’s a solvable puzzle. With systematic diagnosis, the right tools, and respect for electrical fundamentals, most partial failures yield to patient troubleshooting. You’ve learned to distinguish series from segmented wiring, locate the precise fault point, clean corroded contacts, and make repairs that last. More importantly, you now know when repair makes sense—and when replacement is the wiser, safer choice. Don’t let last-minute panic lead to landfill-bound lights or rushed online orders. Take an hour this weekend: unplug, inspect, test, and restore. Your future self—decorating calmly on December 22nd—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?