Accurately measuring a box is more than just a logistical step—it’s a critical component in ensuring product safety, minimizing shipping costs, and optimizing storage efficiency. Whether you're shipping fragile electronics, storing seasonal inventory, or preparing packages for e-commerce fulfillment, getting the dimensions right prevents wasted space, reduces material usage, and avoids carrier penalties. This guide walks through the essential techniques, tools, and best practices to measure any box with precision.

Why Accurate Box Measurement Matters

Inaccurate measurements lead to cascading issues: oversized boxes increase dimensional weight charges, undersized ones risk damaging contents, and mismatched storage containers waste valuable warehouse space. Carriers like UPS, FedEx, and USPS use both actual weight and dimensional (dim) weight to calculate shipping fees. Dim weight is derived from volume—length × width × height—and when it exceeds the actual weight, it becomes the basis for pricing.

For example, a lightweight but bulky package may cost significantly more if its dimensions are not optimized. In warehousing, improperly sized containers can reduce rack utilization by up to 30%, according to logistics experts at the Material Handling Institute. Precision isn’t optional—it’s profit protection.

“Overestimating box size by even an inch on each side can inflate your dim weight by nearly 50%.” — Daniel Reeves, Logistics Optimization Consultant

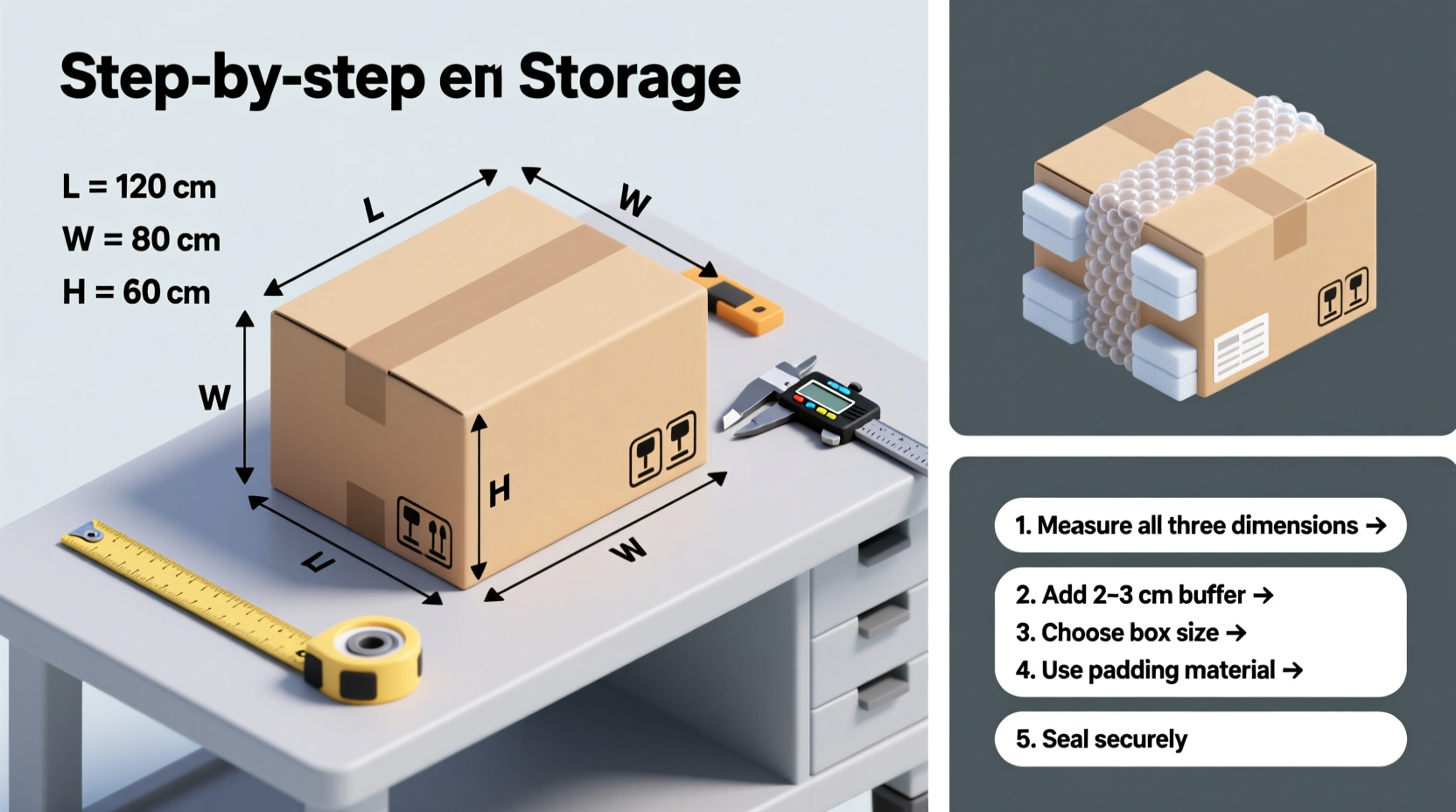

Step-by-Step Guide to Measuring a Box Correctly

Follow this systematic approach to ensure every measurement is reliable and consistent:

- Prepare the box: Use a fully assembled, empty box. If folding flaps, ensure they’re closed as they would be during transit. Do not include tape or padding in your measurement unless those layers permanently alter the box’s footprint.

- Identify orientation: Place the box on a flat surface with the open end facing up. The side with the longest flap is typically considered the top.

- Measure length: Identify the longest horizontal dimension. This is the length. Use a rigid tape measure and extend it from one outer edge to the opposite, measuring across the exterior walls.

- Measure width: The next longest dimension perpendicular to the length is the width. Again, measure from outside to outside.

- Measure height: Measure vertically from the bottom to the top of the box, including any flaps that extend upward when sealed.

- Record all three dimensions: Always list them in the order: Length × Width × Height (L×W×H), which aligns with industry standards.

- Double-check: Re-measure once to confirm consistency, especially if using manual tools.

Common Measurement Mistakes and How to Avoid Them

Even experienced packers make errors that compromise accuracy. Recognizing these pitfalls helps maintain consistency:

- Measuring inside instead of outside: Interior measurements exclude wall thickness, leading to underestimation of total space occupied.

- Ignoring compressed vs. expanded states: Some boxes collapse slightly under load. Measure in their intended shipping state.

- Using flexible rulers or worn tape measures: Stretchable tapes yield inconsistent results. Calibrate tools monthly.

- Forgetting unit standardization: Mixing inches and centimeters causes calculation errors. Stick to one system per operation.

| Mistake | Impact | Solution |

|---|---|---|

| Measuring interior dimensions | Underestimates space used; incorrect dim weight | Always measure external edges |

| Not squaring the box before measuring | Skewed readings due to misalignment | Place on level surface and adjust corners |

| Estimating instead of measuring | Inconsistency across shipments | Use standardized templates or jigs |

| Ignoring manufacturer tolerances | Assumed uniformity where none exists | Verify each batch; don’t assume specs match labels |

Real-World Example: E-Commerce Fulfillment Center Optimization

A mid-sized online retailer selling home goods was experiencing rising shipping costs despite stable sales. An internal audit revealed that warehouse staff were selecting boxes based on visual estimation rather than precise measurement. As a result, average box sizes exceeded product needs by 35%, inflating dim weight charges.

The company implemented a new protocol requiring all outgoing packages to be measured using calibrated rulers and logged into a tracking system. They also introduced pre-sized box stations organized by common product categories. Within six weeks, average box volume decreased by 22%, resulting in a 17% reduction in shipping expenses and improved packing speed. The change paid for itself in under two months.

Choosing the Right Box for Storage vs. Shipping

While the measurement process is similar, the purpose influences selection criteria. A box ideal for long-term storage may not suit shipping demands, and vice versa.

Storage boxes benefit from uniform dimensions to maximize shelving and pallet configurations. Corrugated double-wall or plastic bins work well in climate-controlled environments. Shipping boxes require sufficient burst strength and often need cushioning considerations factored into overall dimensions.

When planning for both uses, create a master list of approved container sizes. This simplifies training, reduces inventory complexity, and ensures compatibility with automated systems.

Essential Tools and Technology for Precision

Manual measurement works for small operations, but scaling requires better tools:

- Digital tape measures: Store readings and convert units instantly.

- Dimensioners: Automated systems that scan boxes and output L×W×H and weight simultaneously—used widely in distribution centers.

- Mobile apps: Some AR-based tools allow smartphone cameras to estimate box size, though they should be verified against physical tools.

- Box-sizing software: Integrates with warehouse management systems (WMS) to recommend optimal container sizes based on item dimensions.

Investing in automation pays off quickly. According to a 2023 report by Supply Chain Dive, companies using dimensioning systems saw a 25–40% improvement in packaging efficiency within the first quarter of deployment.

FAQ: Common Questions About Box Measurement

Should I include packaging materials when measuring?

No. Measure the box itself—the outer carton—without added fillers, bubble wrap, or dividers. However, when calculating internal capacity for product fit, account for padding thickness separately.

What if my box isn’t a perfect rectangle?

For irregularly shaped containers, measure the longest points along each axis. Record the maximum length, width, and height to determine the bounding box—the smallest rectangular prism that can contain the object. Carriers base fees on this envelope.

How often should I verify box dimensions from suppliers?

At minimum, validate dimensions upon initial receipt and after any supplier change. Random audits every 3–6 months help catch production drift. Even minor deviations (±1/8 inch) can accumulate across thousands of units.

Final Checklist: Measuring Boxes Like a Pro

- Use a fully assembled, empty box in its shipping-ready state.

- Measure external dimensions only: Length (longest side), Width (shorter horizontal), Height (vertical).

- Use precise tools—rigid ruler, tape measure, or digital device.

- Record dimensions in L×W×H order, in consistent units (inches or cm).

- Double-check measurements before logging or ordering.

- Factor in intended use—shipping requires attention to carrier rules; storage prioritizes fit and durability.

- Train all team members on standardized procedures to ensure consistency.

Conclusion: Accuracy Starts with a Single Measurement

Every shipment, every stored item, and every customer experience begins with how well you understand the space your products occupy. Measuring a box correctly is not a trivial task—it’s foundational to operational excellence. From reducing avoidable fees to protecting goods in transit, precision delivers tangible returns. Apply these methods consistently, equip your team with the right tools, and treat measurement as a non-negotiable step in your workflow.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?