Air trapped in a swimming pool pump is more than just an annoyance—it can significantly reduce efficiency, strain the motor, and lead to costly repairs over time. When air enters the system, it disrupts water flow, creates noise, and prevents proper circulation. The good news is that removing air from your pool pump is a straightforward process if you understand the mechanics and act promptly. This guide walks you through the causes, symptoms, and most effective methods to purge air and restore peak performance.

Why Air Enters the Pool Pump System

Air infiltration typically occurs due to leaks or improper priming. Common entry points include loose fittings, cracked pump lids, worn gaskets, or low water levels in the pool. Suction-side plumbing—especially around the skimmer, pump lid, and unions—is particularly vulnerable. Once air gets into the system, it accumulates at the highest point: the pump housing or filter tank. Since pumps are designed to move water, not air, even small amounts of trapped air can disrupt operation.

Understanding how air enters helps prevent future issues. For example, a hairline crack in the pump’s O-ring may only leak when the system is under negative pressure (during suction), making it hard to detect unless inspected carefully.

Recognizing the Signs of Air in the Pump

Catching air buildup early prevents long-term damage. Key indicators include:

- Loud gurgling or grinding noises from the pump

- Visible air bubbles in the sight glass or transparent pump lid

- Reduced water flow from return jets

- Pump failing to prime or losing prime shortly after starting

- Increased energy consumption without improved performance

If left unaddressed, these symptoms can escalate. Continuous cavitation—the formation and collapse of air bubbles inside the pump—can erode impeller blades and damage the motor seal. In extreme cases, running a pump dry due to air lock can cause irreversible overheating.

“Air in the pump isn’t just inefficient—it’s destructive. Even brief periods of dry running can compromise the mechanical seal, leading to leaks and full pump replacement.” — Carlos Mendez, Licensed Pool Technician with 18 years of field experience

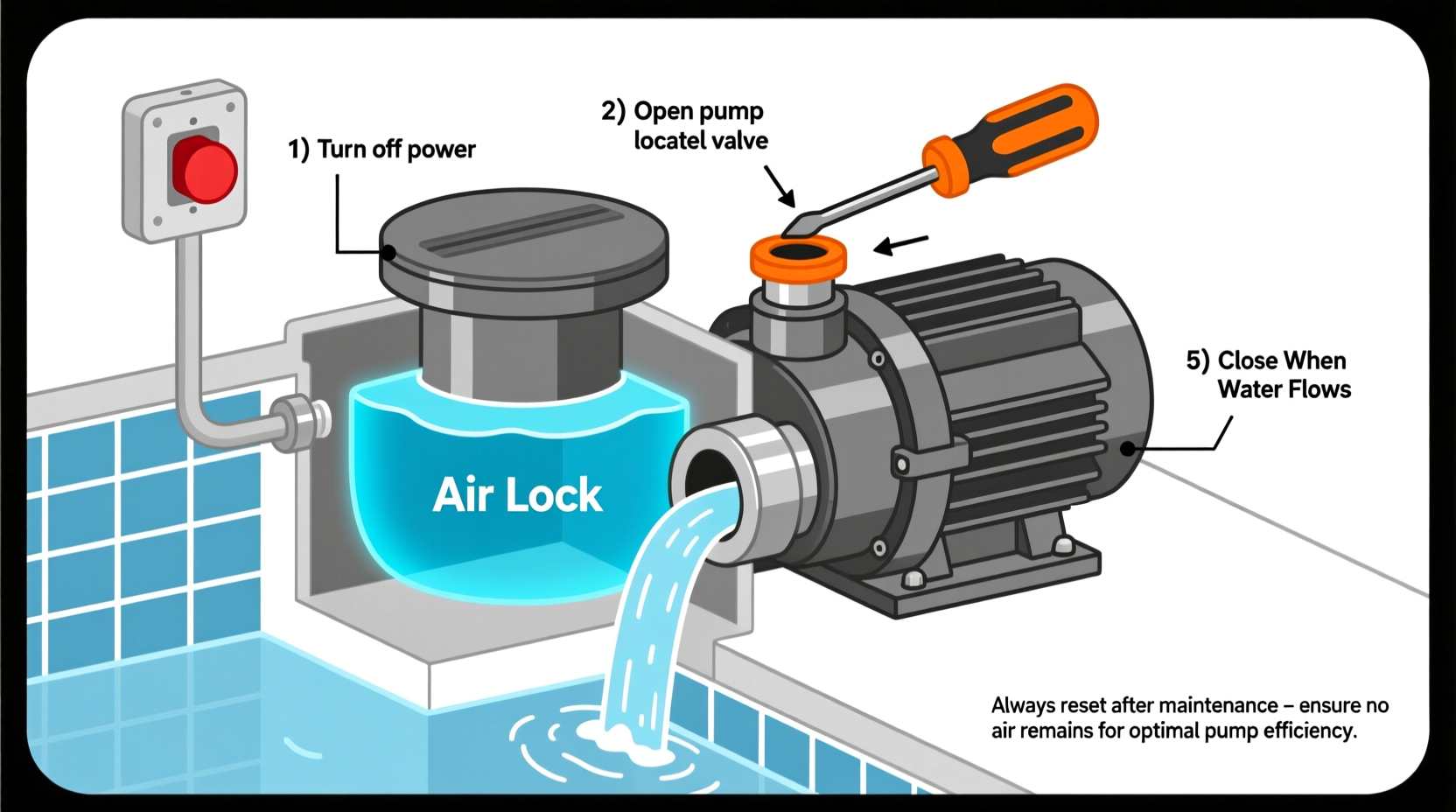

Step-by-Step Guide to Bleeding Air from Your Pool Pump

The following procedure applies to standard above-ground and in-ground pool systems with a vertical discharge pump and a filter tank equipped with an air relief valve. Always turn off the pump before beginning.

- Turn off the pump and power supply. Safety first—shut down the circuit breaker to avoid accidental startup.

- Inspect the pump lid and O-ring. Remove the lid and check the rubber gasket for cracks, warping, or debris. Clean with mild soap and water; replace if damaged.

- Ensure the pool water level is adequate. It should be at least halfway up the skimmer intake. Low water increases the risk of sucking in air.

- Fill the pump basket chamber with water. Use a bucket or hose to completely submerge the interior. This eliminates initial air pockets and aids priming.

- Reinstall the pump lid securely. Hand-tighten only—over-tightening can warp plastic housings or crush the O-ring. <6> Open the air relief valve on the filter. Located on top of the filter tank, this valve releases trapped air once the system pressurizes. <7> Restore power and start the pump. Watch the sight glass or pump housing. You should see air escaping through the relief valve as water begins to circulate. <8> Bleed the air until only water sprays out. Once a steady stream of water emerges from the valve, close it tightly with a quarter-turn. <9> Monitor for 5–10 minutes. Listen for smooth operation and check return jets for consistent flow. If gurgling persists, repeat the process or inspect for leaks.

Common Mistakes That Introduce Air—and How to Avoid Them

Even experienced pool owners make errors that invite air into the system. Below is a comparison of best practices versus common pitfalls.

| Do’s | Don’ts |

|---|---|

| Check and lubricate the O-ring every 3 months | Use petroleum-based lubricants on rubber seals (they degrade them) |

| Tighten union fittings by hand first, then with a wrench if needed | Over-tighten PVC unions, which can crack fittings |

| Keep pool water level above the skimmer intake | Run the pump when the water is below the skimmer line |

| Bleed the filter after backwashing or maintenance | Assume the system will self-prime after service |

| Inspect hoses and valves seasonally for wear | Ignore minor drips—they often indicate larger vacuum leaks |

Real-World Example: Fixing a Persistent Priming Issue

Homeowner Lisa R. in Phoenix reported her pool pump would start normally but lose prime within minutes. She followed standard bleeding procedures weekly, but the issue returned. A technician discovered that while the pump lid seal appeared intact, the skimmer throat’s PVC union had developed a micro-crack due to sun exposure and thermal expansion. During high-suction cycles, the crack allowed air into the line, breaking the prime. Replacing the union fitting and installing a UV-resistant cover resolved the problem permanently. This case underscores that visible components aren’t always the source—sometimes the leak is hidden upstream.

Preventive Maintenance Checklist

To keep your pool pump air-free and running efficiently, perform these checks regularly:

- ✅ Inspect the pump lid O-ring monthly for cracks or dryness

- ✅ Lubricate the gasket with silicone-based sealant every 3 months

- ✅ Verify pool water level stays above the midpoint of the skimmer opening

- ✅ Tighten all pump and filter connections seasonally

- ✅ Bleed the filter tank after any maintenance or prolonged shutdown

- ✅ Listen for abnormal sounds during pump operation

- ✅ Replace worn pump seals or baskets before they fail

Frequently Asked Questions

How often should I bleed air from my pool pump?

You should bleed the air whenever you notice reduced flow, noise, or after performing maintenance like cleaning the filter or replacing parts. Routine bleeding isn’t necessary if the system is sealed properly, but doing it quarterly as part of seasonal care can prevent buildup.

Can I use soapy water to find air leaks?

Yes. Mix dish soap with water and apply it to suspected joints, valves, and connections while the pump is running. If bubbles form, you’ve found a leak. This method is especially useful for detecting small vacuum leaks in threaded or glued fittings.

What happens if I don’t remove air from the pump?

Running a pump with trapped air leads to cavitation, which damages the impeller and motor shaft. Over time, the mechanical seal can burn out, resulting in water leakage into the motor housing and eventual pump failure. Preventative care saves hundreds in replacement costs.

Conclusion: Maintain Flow, Protect Your Investment

Your pool pump is the heart of your circulation system, and air is its biggest enemy. By understanding how air enters, recognizing early signs, and knowing how to purge it effectively, you ensure reliable operation and extend the lifespan of your equipment. Most air-related issues can be resolved in under 15 minutes with basic tools and attention to detail. Don’t wait for performance to drop—stay proactive with routine inspections and simple maintenance.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?