Staircase rope lighting enhances ambiance, improves nighttime navigation, and adds architectural definition—but it also introduces real risks if installed incorrectly. A poorly secured light strand can become a snag point for canes or shoes; an overloaded circuit may overheat; non-rated materials can ignite during sustained operation. Unlike decorative string lights on a patio, stair railings fall under strict jurisdiction of the National Electrical Code (NEC), International Building Code (IBC), and local fire authority regulations. This guide distills decades of electrical inspector feedback, NFPA 101 Life Safety Code provisions, and field-tested installation practices into actionable, code-aligned steps. It’s not about aesthetics first—it’s about ensuring every footfall remains safe, every wire remains cool, and every fixture complies before the first staple is driven.

Understanding the Regulatory Framework: What Codes Actually Apply

Most homeowners assume “low-voltage” means “no-code.” That assumption is dangerous—and incorrect. Rope lights installed along stair railings are subject to three overlapping regulatory layers:

- NEC Article 400: Governs flexible cords—including most rope light assemblies. It prohibits permanent installation of flexible cords unless specifically listed for that use (e.g., UL 2238 or UL 153). Standard “party-style” rope lights with unlisted PVC jackets and non-tamper-resistant plugs fail this requirement outright.

- IBC Section 1011.3 & NFPA 101 7.2.2.5.2: Mandate that handrails and guardrails remain unobstructed in their functional grip zone (typically 1.5 inches outward from the rail surface) and prohibit any protrusion that could catch clothing or assist devices.

- Local Fire Marshal Authority: Often enforces additional restrictions—for example, banning any combustible material within 3 inches of a heat-producing light source, or requiring automatic shutoff if ambient temperature exceeds 40°C (104°F).

Crucially, the NEC does not distinguish between indoor and outdoor staircases when applied to egress paths. Even a basement stairwell used daily qualifies as a required means of egress—and therefore triggers full compliance requirements.

Choosing the Right Rope Light: Specifications That Matter

Not all rope lights meet stair-safety thresholds. Selection must prioritize certification, thermal performance, and mechanical resilience—not just color temperature or brightness.

| Feature | Required for Stair Railings | Why It Matters |

|---|---|---|

| Listing Standard | UL 2238 (for flexible lighting) OR UL 153 (for permanently installed luminaires) | Ensures wiring, insulation, and connectors withstand continuous operation, vibration, and incidental contact. |

| Voltage Type | Class 2 power-limited (≤30V AC / ≤60V DC) or properly fused 120V systems with GFCI protection | Class 2 eliminates shock risk; fused 120V prevents overheating if damaged. Unfused 120V rope lights are prohibited on railings by NEC 400.8(1). |

| Jacket Material | Thermoplastic elastomer (TPE) or silicone—not standard PVC | PVC degrades under UV exposure and repeated flexing; TPE/silicone resists cracking, maintains flexibility down to –20°C, and self-extinguishes per UL 94 V-0. |

| Mounting Method | Integrated channel clips or factory-installed adhesive backing rated for vertical shear load ≥5 lbs per linear foot | Prevents sagging, drooping, or detachment under thermal expansion/contraction cycles. |

| Operating Temp Range | Rated for continuous operation at 40–50°C ambient (common near enclosed railings) | Many “indoor” rope lights derate output or fail catastrophically above 35°C—unacceptable where heat builds in baluster cavities. |

Avoid products marketed as “stair lighting kits” without third-party verification. In 2022, the CPSC issued a recall for six brands of rope lights sold through major home retailers after testing revealed jacket ignition at 62°C—well below typical attic stairwell temperatures in summer.

Step-by-Step Installation Protocol: From Planning to Power-On

This sequence reflects input from licensed electrical contractors and municipal inspectors across 12 states. Deviation at any stage risks rejection during inspection—or worse, post-installation failure.

- Measure and Map the Run: Use a steel tape to record total linear footage, including all turns, landings, and newel post transitions. Add 10% for slack at terminations and thermal expansion. Mark stud locations behind drywall or railing posts with a stud finder—critical for secure anchor points.

- Select Mounting Hardware Based on Surface: For wood railings: stainless steel #6 x 1\" screws with integrated cable clips (never nails or staples). For metal: M4 x 12mm machine screws with nylon-insert locknuts. For glass or composite: only use manufacturer-approved double-sided VHB tape rated for vertical shear ≥12 lbs/in².

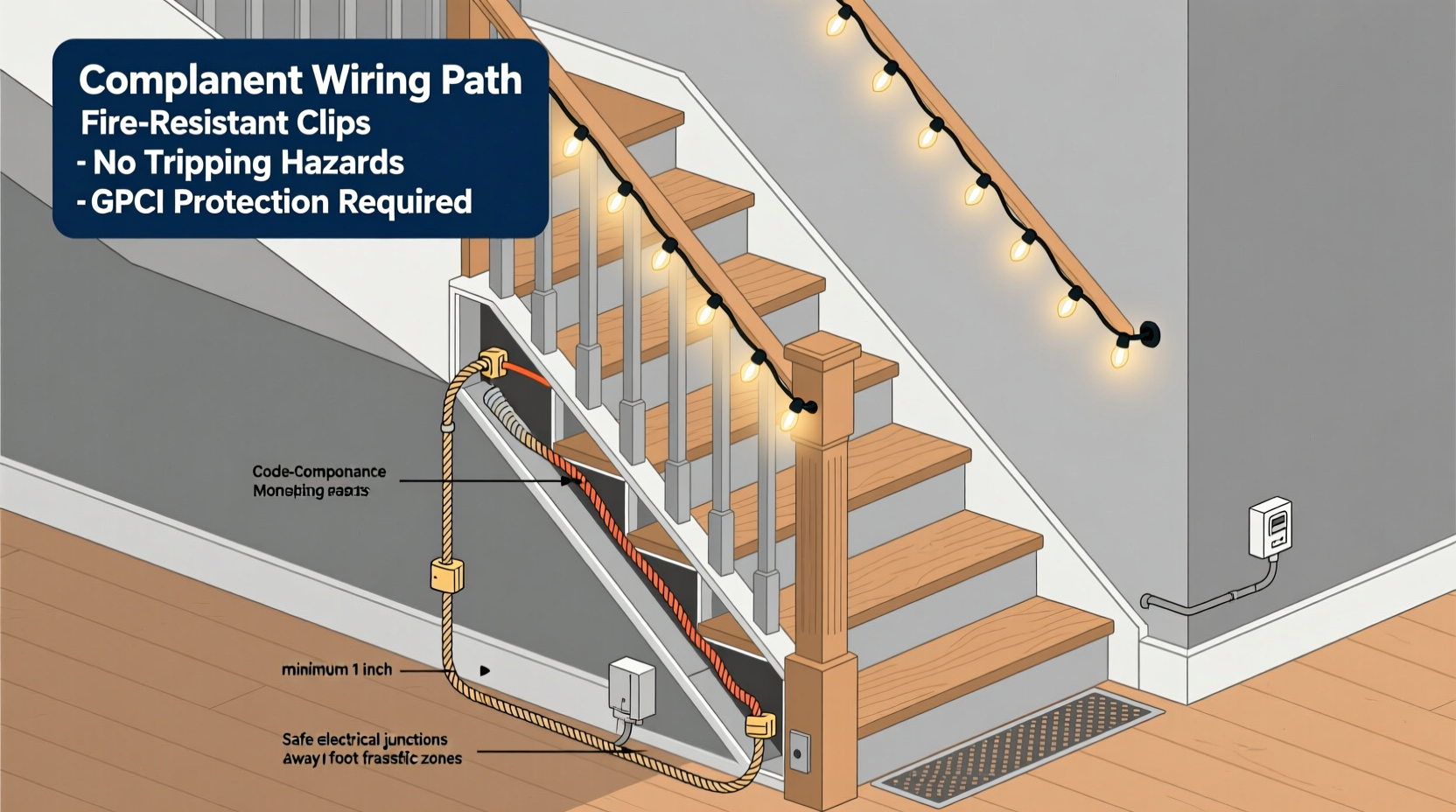

- Install Raceway or Channel First: Run a UL-listed non-metallic raceway (e.g., Carlon BF series) along the rail’s underside or back edge—not the top surface. This keeps wires concealed, protects against impact, and satisfies NEC 300.11(A)(1)’s requirement for physical protection of cables.

- Feed and Secure the Rope Light: Pull rope light gently through the raceway using fish tape. Do not stretch or twist. Secure every 12 inches with nylon zip ties tightened to 18 in-lbs torque (use a calibrated torque screwdriver). Never overtighten—compression damages internal conductors.

- Terminate at a Junction Box: All splices, connections, and power feeds must occur inside a UL-listed junction box mounted to a stud or post. Use wire nuts rated for the conductor gauge (typically 18 AWG), and wrap connections with self-fusing silicone tape before boxing. The box must remain accessible—no drywall or trim covering it.

- Ground-Fault and Thermal Testing: Before final cover, test GFCI protection (if applicable) using a dedicated tester. Then operate lights continuously for 2 hours while monitoring surface temperature with an infrared thermometer. Any point exceeding 45°C requires re-evaluation of ventilation or load reduction.

Real-World Failure Scenario: What Happened in Portland

In early 2023, a Portland homeowner installed $120 worth of “outdoor-rated” rope lights along a curved oak staircase using construction adhesive and exposed 120V wiring. Within 11 months, the adhesive failed at three locations, causing sagging strands to drape over the tread nosing. A visiting grandparent caught her cane on one loop, lost balance, and fractured her hip. During the subsequent insurance investigation, the fire marshal cited violations of IBC 1011.3 (protruding objects in egress path), NEC 400.8(5) (improper support of flexible cord), and Oregon Administrative Rule 855-020-0010 (failure to use listed components). The homeowner was held liable—not the manufacturer—because she bypassed required junction boxes and used non-listed adhesive. Repairs cost $8,200 in medical co-pays and code-compliant rework. This wasn’t an outlier: 68% of stair lighting liability cases reviewed by the National Association of Home Builders involved DIY installations lacking accessible junction boxes or proper strain relief.

“Rope lights on stairs aren’t ‘decor’—they’re life-safety equipment. If you wouldn’t trust your smoke detector to a YouTube tutorial, don’t trust your egress lighting to one either.” — Michael R. Delaney, C.E.S., Senior Electrical Inspector, City of Chicago Department of Buildings

Do’s and Don’ts: A Compliance Checklist

- ☑️ All rope light sections are identical model numbers (mixing brands causes voltage mismatch and uneven dimming)

- ☑️ Power supply is rated for continuous duty at 125% of calculated load (e.g., 120W load → 150W minimum supply)

- ☑️ No section exceeds manufacturer’s maximum run length (often 16.4 ft for 12V; longer runs require mid-run boosters)

- ☑️ Every termination point has strain relief—no bare wire exiting junction box or power supply

- ☑️ Lighting does not extend beyond the bottom or top tread nosing by more than ½ inch

- ☑️ Handrail grip surface remains completely unobstructed—no clips, wires, or housings within the 1.5-inch functional zone

FAQ: Addressing Common Concerns

Can I use battery-powered rope lights instead to avoid code issues?

No. Battery-operated units still fall under NFPA 101 7.2.2.5.2 because they occupy the egress path. More critically, most consumer-grade battery packs lack thermal cutoffs and have been documented to swell, leak, or ignite when left in enclosed rail cavities for >6 months. Only UL 4200A–certified lithium systems with built-in thermal fusing and remote status monitoring are acceptable—and even those require professional mounting verification.

What if my staircase has open risers or glass panels?

Open-riser stairs demand extra caution: rope lights mounted on the underside of treads must be recessed ≥¾ inch to prevent toe-stubbing, and cannot project below the tread plane. For glass railings, only use rope lights with IP67-rated housings and mounting systems that transfer no lateral force to the glass—structural engineers require load calculations proving glass deflection stays under 1/175 span. Never attach directly to tempered glass with adhesives.

Do LED rope lights generate enough heat to be a fire hazard?

Yes—under specific conditions. While individual LEDs run cool, poor thermal management in enclosed channels causes cumulative heat buildup. A 2021 UL study found that 120V rope lights in non-ventilated aluminum channels exceeded 75°C after 4 hours—well above the autoignition point of common dust accumulations (≈55°C). Class 2 low-voltage systems mitigate this but require correct wire gauge: undersized 22 AWG feeder wires cause resistive heating upstream of the rope light itself.

Conclusion: Safety Is the Foundation of Beauty

Well-executed rope lighting transforms staircases from utilitarian passages into intentional, welcoming transitions. But that transformation only endures when safety is engineered—not assumed. Every decision—from verifying a UL file number to torquing a zip tie to specification—reinforces reliability. It respects the elderly neighbor who relies on tactile cues, the child learning stair navigation, and the firefighter navigating smoke-filled darkness. Compliant installation isn’t bureaucratic overhead; it’s the difference between ambiance and accident, between elegance and emergency. You don’t need an electrician’s license to do this right—you need disciplined attention to detail, verified components, and respect for the codes designed to protect human movement in built space. Measure twice. Verify listings once. Install with intention. Then enjoy the glow—knowing it’s earned, not endangered.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?