When your Christmas lights fail to illuminate, the culprit is often a blown fuse — especially in older incandescent strands. While a multimeter is the most accurate tool for diagnosing electrical issues, not everyone keeps one on hand during the holiday season. The good news? You don’t need advanced equipment to check if a fuse is the problem. With everyday household items and a few clever tricks, you can test Christmas light fuses quickly and safely, restoring your festive glow in minutes.

This guide walks through practical, no-multimeter methods that deliver reliable results. Whether you're troubleshooting indoor string lights or outdoor displays, these techniques are accessible to all skill levels and require minimal tools.

Understanding Christmas Light Fuses

Most traditional incandescent Christmas light strands contain small glass fuses housed inside the plug. These fuses protect the circuit from power surges and overheating. A typical strand has two fuses: one for each side of the AC line. When one blows, the entire string may go dark — even if the bulbs appear intact.

Fuses in Christmas lights are usually rated at 3 or 5 amps and measure about half an inch long. They’re encased in clear glass with metal ends and a thin wire running through the center. If that wire is broken or blackened, the fuse is likely blown.

“Over 70% of non-working Christmas light strands have a blown fuse as the root cause.” — National Electrical Manufacturers Association (NEMA)

Before diving into testing methods, always unplug the lights. Working with live circuits increases the risk of shock, especially when handling small components like fuses.

Visual Inspection: The First Line of Diagnosis

The fastest way to assess a fuse without any tools is a careful visual inspection. This method won’t catch every failure, but it identifies the majority of blown fuses immediately.

- Unplug the light strand completely.

- Locate the fuse compartment on the male end of the plug. It typically slides open with gentle pressure or a small flathead screwdriver.

- Carefully remove both fuses using tweezers or your fingers.

- Hold each fuse up to a bright light source.

- Examine the thin wire inside the glass tube.

If the wire is intact and unbroken, the fuse may still be functional. However, if you see:

- A visible gap in the wire

- Black or dark gray discoloration inside the glass

- Charred or melted appearance at the ends

— then the fuse is blown and needs replacement.

Testing Fuses Using a Known Working Light Strand

If visual inspection doesn’t provide a clear answer, use a working set of compatible Christmas lights to test the suspect fuse. This method leverages existing equipment to verify functionality without electricity or special tools.

Step-by-Step Guide: Fuse Swap Test

- Take a second strand of Christmas lights that is known to work properly.

- Unplug it and open its fuse compartment.

- Remove one of its good fuses and set it aside safely.

- Insert the suspect fuse into the working strand’s fuse slot.

- Plug in the working strand.

- Observe the behavior:

- If the previously working strand now fails to light, the suspect fuse is likely blown.

- If it continues to operate normally, the suspect fuse is functional.

Repeat the process with the second suspect fuse if applicable.

This method works because a blown fuse breaks the circuit. By introducing the questionable fuse into a known-good system, you isolate the variable. If the system fails, the introduced component is the issue.

“Sometimes the simplest diagnostic is substitution. If the symptom follows the part, the part is guilty.” — Harold Finch, Residential Electrician (25+ years experience)

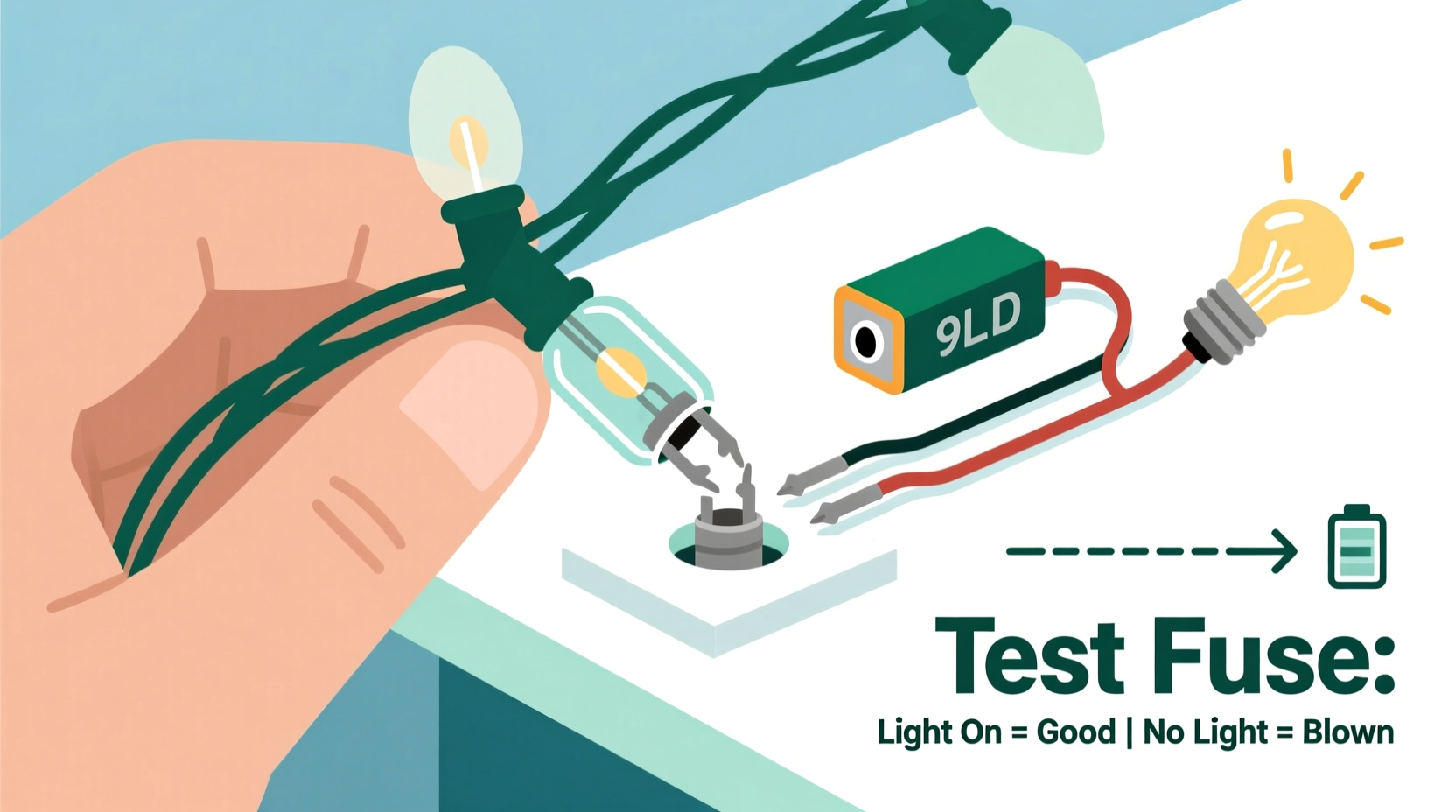

Using a Battery and Bulb Tester (DIY Continuity Check)

You can build a basic continuity tester using common household items. This method confirms whether electricity can flow through the fuse — a direct indicator of its condition.

What You’ll Need:

- A AA or AAA battery (1.5V)

- A small flashlight bulb (1.5V or 3V)

- Two pieces of wire (6–8 inches long, stripped at both ends)

- The suspect fuse

Assembly Instructions:

- Connect one wire from the negative terminal of the battery to the metal side of the bulb holder (or twist directly onto the bulb base).

- Attach the second wire to the bottom contact point of the bulb.

- Touch one end of the fuse to the free end of the first wire (connected to the battery).

- Touch the other end of the fuse to the free end of the second wire (connected to the bulb).

If the fuse is good, the circuit completes and the bulb lights up. If the bulb remains dark, the fuse is blown.

This setup mimics a basic closed circuit. A functioning fuse allows current to pass, illuminating the test bulb. A break in the fuse interrupts the flow.

| Outcome | Meaning | Action |

|---|---|---|

| Bulb lights up | Fuse has continuity | Fuse is likely good |

| Bulb does not light | No continuity | Fuse is blown — replace it |

| Bulb flickers | Intermittent connection | Replace fuse — unreliable |

Note: This method uses low voltage and is safe for home use. Do not attempt with wall power or higher-voltage batteries.

Real-World Example: Sarah’s Front Porch Lights

Sarah had been using the same set of red-and-green incandescent lights on her porch for seven years. One November evening, she plugged them in — nothing happened. All the bulbs looked fine, and the outlet was working. She didn’t own a multimeter.

She removed the two fuses and inspected them under her kitchen light. One showed a faint dark smudge near the center. Not sure if it was significant, she used her daughter’s battery-powered science kit — including wires and a small bulb — to run a continuity test.

The visibly damaged fuse failed to complete the circuit. The second fuse lit the test bulb instantly. She replaced the bad one with a spare from a broken strand she’d saved, plugged everything back in, and her display lit up perfectly.

From discovery to fix: less than ten minutes. No trips to the store, no expensive tools.

Quick Checklist: How to Test a Fuse Without a Multimeter

- ✅ Unplug the light strand before handling fuses

- ✅ Open the fuse compartment on the plug

- ✅ Remove both fuses carefully

- ✅ Inspect each fuse visually for breaks or discoloration

- ✅ Use a working light strand to swap and test fuses

- ✅ Build a DIY continuity tester using a battery and small bulb

- ✅ Replace blown fuses with identical-rated ones (same amps and size)

- ✅ Reassemble and test the full strand after repair

Common Mistakes to Avoid

Even simple procedures can go wrong if precautions aren’t taken. Here are frequent errors people make when testing fuses without proper tools:

- Assuming all fuses are the same — Always verify amperage. Using a 7A fuse in a 3A-rated string creates a fire hazard.

- Forcing the fuse compartment — These parts are fragile. Use gentle pressure or a plastic tool to avoid cracking the plug.

- Testing while plugged in — Never probe fuses while the strand is connected to power.

- Ignoring both fuses — Some strands fail due to a single blown fuse, but both should be checked.

- Using damaged replacements — Even new fuses can be defective. Test spares if possible.

Frequently Asked Questions

Can I test a fuse by shaking it?

No. While some people claim they can hear a “rattle” if the filament is broken, this is unreliable. Many blown fuses don’t produce sound, and loose debris in the glass can mimic the noise. Rely on visual or electrical testing instead.

Where can I get replacement fuses?

Most hardware stores carry Christmas light fuse packs in the holiday section during November and December. You can also order them online year-round. Keep a spare pack on hand for future repairs. Some light sets include extras in the storage cap or tucked in the cord wrap.

Why did my fuse blow in the first place?

Fuses typically blow due to power surges, moisture exposure (for outdoor sets), daisy-chaining too many strands together, or using incompatible extension cords. To prevent recurrence, follow manufacturer guidelines on maximum connectable lengths and use surge-protected outlets.

Final Tips for Long-Term Light Maintenance

Prevention is just as important as repair. Extend the life of your Christmas lights with these habits:

- Store lights on reels or cardboard forms to prevent tangling and stress on wires.

- Keep them in a dry, temperature-stable location — garages and attics can expose lights to extreme conditions.

- Inspect strands annually before use, checking for cracked sockets, frayed wires, and corroded fuses.

- Label repaired strands so you remember which ones have had past issues.

Conclusion: Bring Back the Brightness — Fast

Testing Christmas light fuses without a multimeter isn’t just possible — it’s simple and effective when you know how. From visual checks to smart swaps and DIY testers, you have multiple reliable options at your fingertips. These methods save time, reduce waste, and keep your holiday spirit glowing without unnecessary expense.

Don’t let a tiny glass tube dim your decorations. With a few minutes and basic tools, you can diagnose and resolve the issue like a pro. Next time your lights go out, stay calm, unplug, inspect, and act. Your perfect holiday display is only a fuse away.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?