A malfunctioning ice maker can be a major inconvenience, especially during hot months or when hosting guests. While modern refrigerators come equipped with advanced ice systems, they’re not immune to failure. The good news is that most issues have straightforward solutions. Understanding the root causes—ranging from simple clogs to electrical faults—can save time, money, and unnecessary service calls.

This guide dives into the most frequent reasons an ice maker stops working, offering practical diagnostics and fixes you can perform at home. Whether your unit produces no ice, makes odd noises, or dispenses poorly shaped cubes, these insights will help restore function efficiently.

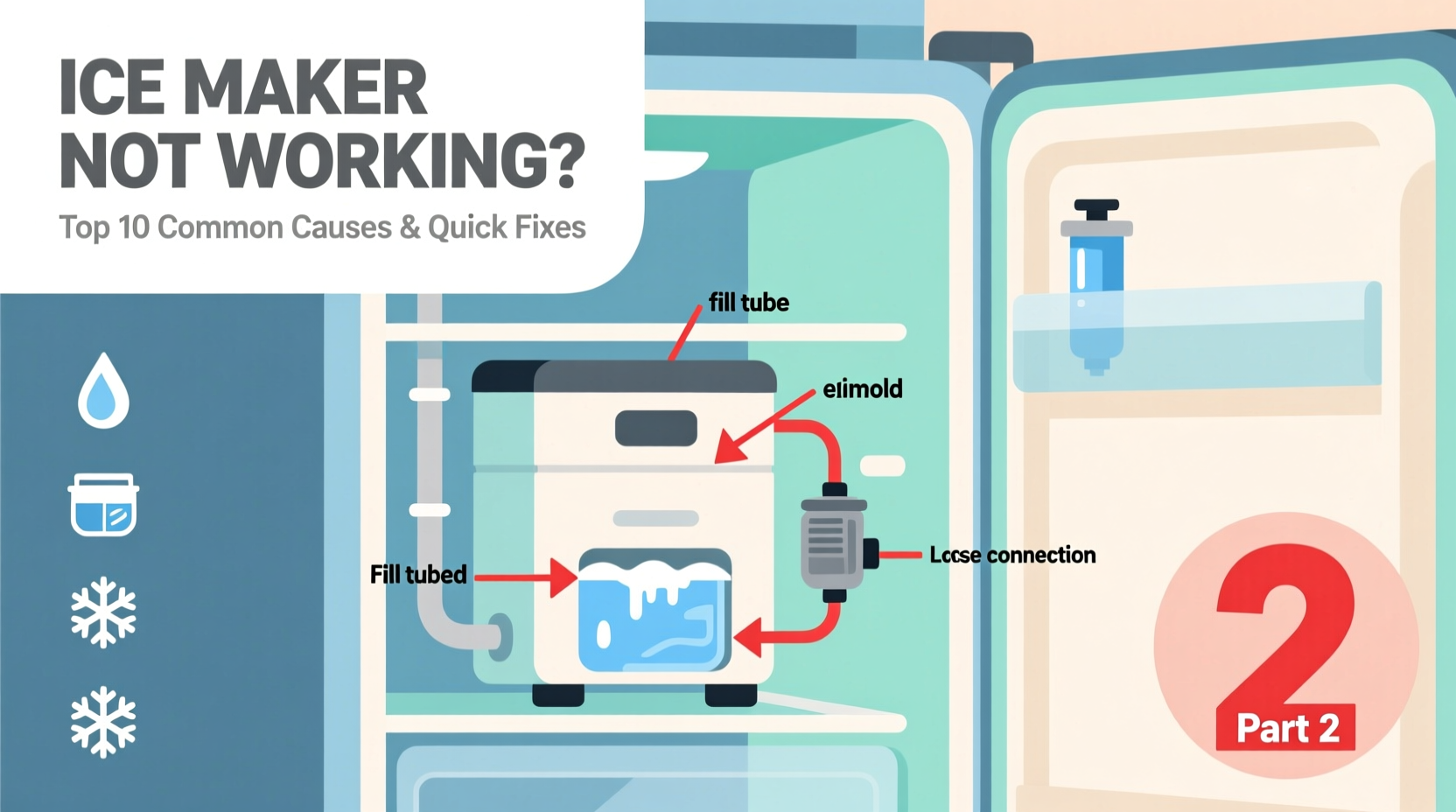

Common Causes of Ice Maker Failure

Before reaching for tools or calling a technician, identify where the problem lies. Most ice maker issues stem from one of several predictable sources:

- Water supply interruption – No water means no ice.

- Freezer temperature too high – Ice won’t form if it’s not cold enough.

- Clogged water filter or line – Restricted flow prevents proper filling.

- Malfunctioning inlet valve – This part controls water entry; if faulty, it halts production.

- Ice blockage in the mold or chute – Old ice can jam mechanisms.

- Electrical issues – Tripped switches, blown fuses, or wiring problems disrupt operation.

- Control module failure – In newer models, electronic boards may fail silently.

Step-by-Step Troubleshooting Guide

Follow this logical sequence to isolate and resolve the issue without guesswork.

- Check power and settings: Confirm the ice maker is turned on. Some units have a toggle switch or feeler arm that must be in the down position. If the arm is up, it signals “full,” stopping production.

- Verify freezer temperature: Use a standalone thermometer. Ideal range is between 0°F and 5°F (-18°C to -15°C). If warmer, adjust thermostat and wait 24 hours.

- Inspect water supply line: Trace the line from the wall to the fridge. Look for kinks, especially behind the unit. Disconnect and blow through it to test for blockages.

- Test water pressure: Low pressure results in underfilled molds. Remove the line at the valve, place it in a cup, and turn on the water briefly. A steady stream should fill a cup in 10–15 seconds.

- Replace or flush the water filter: Even if recently installed, filters can clog prematurely. Consult your manual for location and replacement schedule.

- Examine the inlet valve: Located near the water line connection, this solenoid valve opens to let water in. If it doesn’t click during a cycle, it may need replacement.

- Clear ice jams: Remove any frozen clumps from the ejection area or storage bin. Use warm (not hot) water to melt stubborn ice.

- Listen for motor sounds: During a cycle, you should hear a faint hum or gear movement. Silence suggests a failed motor or control board.

Troubleshooting Checklist

Use this checklist to methodically evaluate your ice maker’s condition:

- ✅ Ice maker switch is ON

- ✅ Freezer temperature below 5°F (-15°C)

- ✅ Water supply valve fully open

- ✅ Supply line free of kinks or cracks

- ✅ Water filter replaced within last 6 months

- ✅ Inlet valve clicks during fill cycle

- ✅ No ice buildup blocking ejector blades

- ✅ Power cord securely plugged in

- ✅ No error codes on display panel (if applicable)

Do’s and Don’ts When Fixing Your Ice Maker

| Do | Don’t |

|---|---|

| Unplug the refrigerator before servicing | Use sharp tools to chip away ice (risk of damaging components) |

| Flush the water line annually | Ignore persistent low water pressure |

| Replace filters every 6 months | Force the feeler arm down if ice is already present |

| Keep the ice bin clean and dry | Use chemical cleaners inside the ice maker |

| Consult the user manual for model-specific guidance | Assume the problem is complex without checking basics first |

Real-World Example: Resolving a Frozen Fill Tube

One homeowner reported their Samsung side-by-side refrigerator stopped making ice despite normal freezer temps and power. After verifying the switch was on and the filter replaced, they noticed no water entering the mold during a cycle. Further inspection revealed a small drip from the back of the freezer compartment—a clue pointing to the fill tube.

Using a hairdryer on low heat, they gently warmed the area above the ice maker where the water line enters from behind the wall. Within minutes, a trickle of water followed by full flow confirmed the tube had been frozen shut. The system resumed normal operation after a 3-hour recovery period.

This case highlights how environmental factors—like a brief power outage causing partial thaw/refreeze—can create hidden obstructions even in well-maintained units.

Expert Insight on Preventive Maintenance

“Most ice maker failures aren’t due to component wear but neglect. A clogged filter or undetected kink in the line accounts for over 70% of service calls we see.” — Carlos Mendez, Appliance Repair Technician with 18 years of field experience

Regular maintenance isn’t just about replacing parts—it’s about ensuring consistent conditions for optimal performance. Cleaning the ice bin every three months, monitoring water quality, and checking line integrity twice a year can prevent most issues before they start.

Frequently Asked Questions

Why does my ice maker make noise but produce no ice?

The sound indicates the motor is running, but the lack of ice suggests a water delivery problem. Check the inlet valve, water pressure, and fill tube for freezing. If the mold remains dry, the issue is likely upstream of the ice maker itself.

Can a dirty water filter stop ice production?

Yes. A severely clogged filter restricts water flow to the point where the fill cycle fails. Even if some water gets through, insufficient volume prevents proper freezing and ejection. Replace filters as recommended—typically every six months.

Is it worth repairing an older ice maker?

For units over 8–10 years old, consider cost versus benefit. A new inlet valve ($40–$80) or motor module ($100–$150) may extend life, but recurring issues could signal broader system degradation. Weigh repair costs against the price of a newer, more efficient model.

Final Steps and Long-Term Care

Once your ice maker is functioning again, take steps to ensure lasting reliability. Reset the system by turning it off for five minutes, then restarting. Monitor the first few cycles to confirm consistent fill, freeze, and ejection.

Consider installing a whole-house water filtration system if your tap water contains high sediment or minerals. Hard water leads to scale buildup in valves and lines, shortening component lifespan. Additionally, keep the condenser coils clean—dust buildup reduces cooling efficiency, indirectly affecting ice production.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?