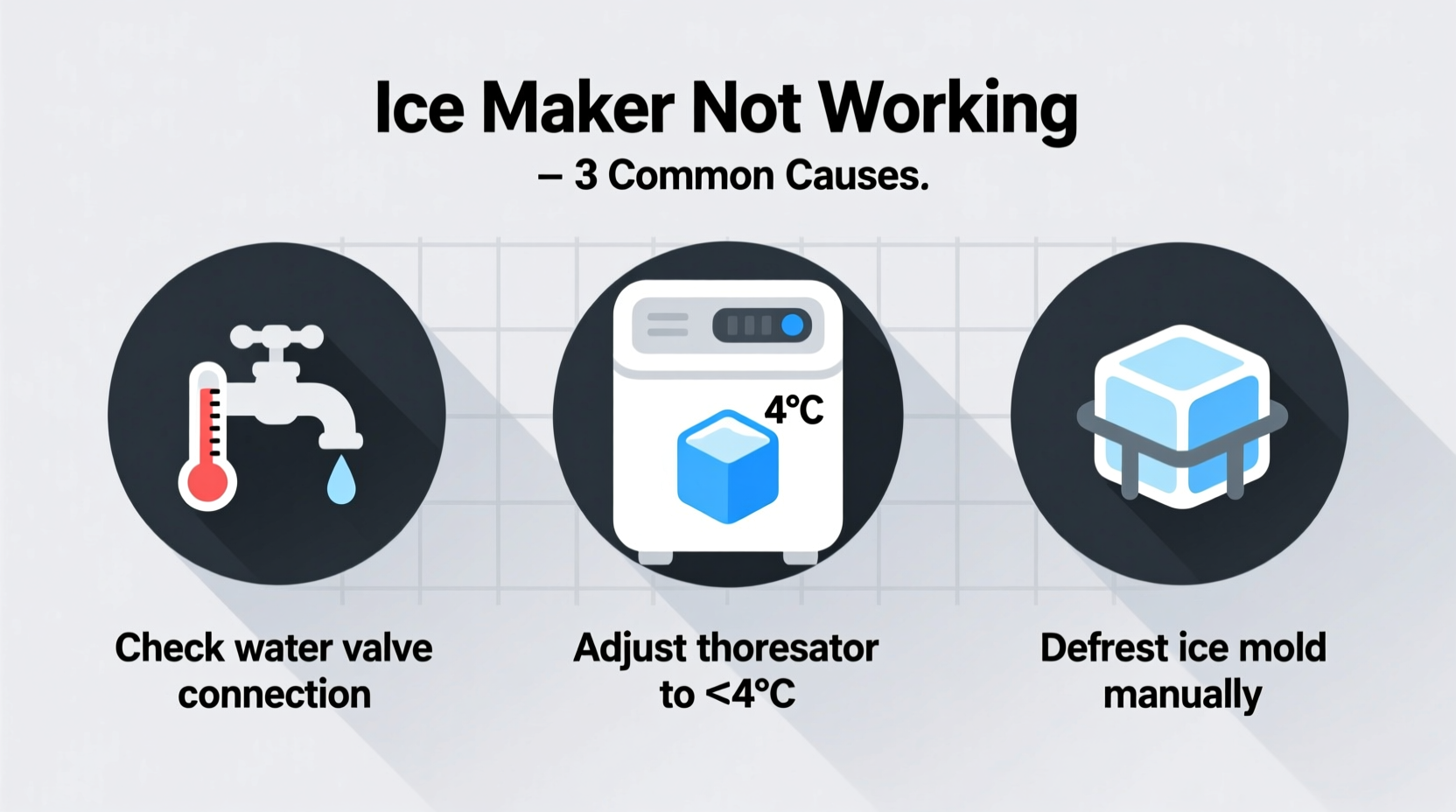

A malfunctioning ice maker is more than a minor inconvenience—it disrupts daily routines, affects beverage service, and can signal deeper issues within your refrigerator system. While some problems require professional repair, many are simple to diagnose and resolve at home. Understanding the three most common causes behind an ice maker failure empowers homeowners to restore functionality quickly, save on service calls, and extend appliance life.

This guide dives into real-world diagnostics, offering actionable steps backed by appliance technicians and user experiences. Whether your ice maker produces no ice, makes odd noises, or leaks water, the answers often lie in overlooked but easily accessible components.

1. Water Supply Issues: The Silent Ice Killer

The first and most frequent culprit behind a non-working ice maker is inadequate or interrupted water supply. Without consistent water flow, even a perfectly functioning mechanism cannot produce ice. This issue is especially common in refrigerators connected to homes with older plumbing, low water pressure, or recently installed water filters.

Water enters the ice maker through a small valve controlled by an electrical signal. If this line becomes kinked, clogged, or frozen, the valve may open—but deliver little or no water. Homeowners often overlook this because the refrigerator appears otherwise operational.

How to Diagnose Water Flow Problems

- Locate the water inlet valve at the back of the refrigerator.

- Disconnect the supply line and place it into a bucket.

- Have someone activate the water dispenser (if available) or manually trigger the ice cycle.

- Observe flow rate—should be steady and strong.

If flow is weak or absent, trace the line from the fridge to the main water source. Common blockages include sediment buildup in the filter or a partially closed shutoff valve. Replace filters every six months, even if they don’t appear dirty—mineral deposits can restrict flow over time.

“Over 40% of ice maker service calls I handle turn out to be nothing more than a clogged filter or shut-off valve. It’s always worth checking the basics first.” — Daniel Ruiz, Appliance Repair Technician with 15 years of field experience

2. Freezer Temperature Too High

An ice maker depends on a consistently cold environment to function. If the freezer temperature rises above 15°F (-9°C), the unit may pause operation or fail to cycle properly. Modern ice makers have built-in sensors that prevent activation unless conditions are optimal.

Many users assume their freezer is cold enough because food remains frozen. However, partial cooling—such as when the door seal degrades or the defrost system fails—can allow temperatures to hover just above freezing, halting ice production while still preserving contents.

Step-by-Step: Verify Freezer Performance

- Place a glass of water in the freezer and insert a thermometer.

- Wait 2 hours without opening the door.

- Check the reading: below 10–15°F is ideal for ice production.

- If above 15°F, investigate further.

Common reasons for elevated temperatures include:

- Damaged or misaligned door gasket allowing warm air infiltration

- Dust-clogged condenser coils reducing cooling efficiency

- Faulty evaporator fan not circulating cold air

- Defrost system malfunction causing frost buildup on coils

3. Mechanical or Electrical Failures in the Ice Maker Unit

When water and temperature are confirmed adequate, the problem likely lies within the ice maker assembly itself. Components such as the mold heater, motor, or control module can degrade over time due to mineral buildup, wear, or power surges.

Signs of internal failure include:

- No sound during cycle attempts

- Ice cubes stuck in the mold

- Motor runs but no ejection occurs

- Water overflows into the bin

In modular units (common in Whirlpool, Kenmore, and KitchenAid models), the entire module can be replaced in under 30 minutes. Older or integrated systems may require more disassembly but still offer user-replaceable parts like gears and harvest heaters.

Mini Case Study: Sarah’s Intermittent Ice Maker

Sarah in Denver noticed her ice maker worked only once every few days. She verified water flow and confirmed the freezer was at 8°F. After watching a YouTube tutorial, she removed the ice maker and found ice bridged across the sensing arm, tricking the unit into thinking the bin was full. Once cleared and dried, the unit resumed normal operation. Later, she discovered a recurring freeze-up due to a slow water fill—replacing the inlet valve fixed the root cause.

This example illustrates how multiple factors can compound. Clearing ice resolved the immediate issue, but only addressing the slow fill prevented recurrence.

Troubleshooting Checklist: Fast-Track Your Diagnosis

Use this checklist to methodically identify the cause:

- ✅ Is the freezer temperature below 15°F?

- ✅ Is the water filter new or recently replaced?

- ✅ Is the water shutoff valve fully open?

- ✅ Is the supply line kinked or frozen?

- ✅ Does the water dispenser work? (If yes, water supply is likely OK)

- ✅ Is the ice maker turned on? (Check toggle switch or feeler arm position)

- ✅ Are there visible signs of ice jamming the ejector blades?

- ✅ Does the unit make a humming or clicking sound during cycle?

Do’s and Don’ts of Ice Maker Maintenance

| Do | Don't |

|---|---|

| Replace water filters every 6 months | Ignore persistent clunking or grinding sounds |

| Clean the ice bin and mold quarterly | Use sharp tools to break ice—risk damaging components |

| Ensure proper clearance around the fridge for airflow | Store food near the ice maker vent that blocks airflow |

| Inspect door seals annually | Assume no ice = broken ice maker (check water and temp first) |

Frequently Asked Questions

Why did my ice maker stop working after I changed the water filter?

This is surprisingly common. Air trapped in the line after filter replacement can prevent water from reaching the ice maker. Run the water dispenser for 1–2 minutes to purge air. If no water flows, ensure the filter is seated correctly—some models won’t allow flow if the filter isn’t locked in place.

Can a frozen fill tube cause complete ice maker failure?

Yes. The fill tube runs from the back of the fridge into the freezer compartment. If it freezes shut, water can’t enter the mold. To fix: disconnect power, locate the tube (usually near the top rear inside the freezer), and use a hair dryer or warm cloth to thaw it. Prevent recurrence by checking water pressure—slow flow increases freeze risk.

Is it worth repairing an ice maker, or should I replace it?

For modular units, replacement is often cheaper and faster than repair. OEM modules range from $70–$150 and install in under 30 minutes. For integrated systems, consult a technician if basic checks fail. However, if the fridge is over 10 years old, consider upgrading to a model with improved reliability.

Conclusion: Take Action Before You’re Out of Ice

An ice maker not working doesn’t automatically mean disaster. Most failures stem from one of three manageable causes: disrupted water supply, incorrect freezer temperature, or mechanical jams. By following a logical diagnostic process—starting with the simplest explanations—you can often restore function in less than an hour.

Regular maintenance, including filter changes and coil cleaning, prevents many issues before they start. Pay attention to subtle signs: slower fill times, smaller cubes, or irregular cycling. These are early warnings your system needs attention.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?