A malfunctioning ice maker is more than a minor inconvenience—it can disrupt daily routines, affect food storage efficiency, and turn simple tasks like making drinks into frustrating chores. Whether your refrigerator’s ice maker has stopped producing ice entirely or is underperforming, diagnosing the issue early can prevent further damage and costly repairs. Most problems stem from easily identifiable sources such as water supply issues, temperature fluctuations, or mechanical failures. Understanding these root causes empowers homeowners to take quick, effective action.

Common Signs Your Ice Maker Needs Attention

Before diving into fixes, recognize the symptoms of a failing ice maker:

- No ice production despite power and settings being on

- Small or misshapen ice cubes

- Intermittent operation—cycles sometimes but not consistently

- Unusual noises during operation (grinding, clicking)

- Water leakage around the freezer compartment

These signs point to underlying issues that range from simple user errors to component failure. The key is systematic diagnosis rather than immediate replacement.

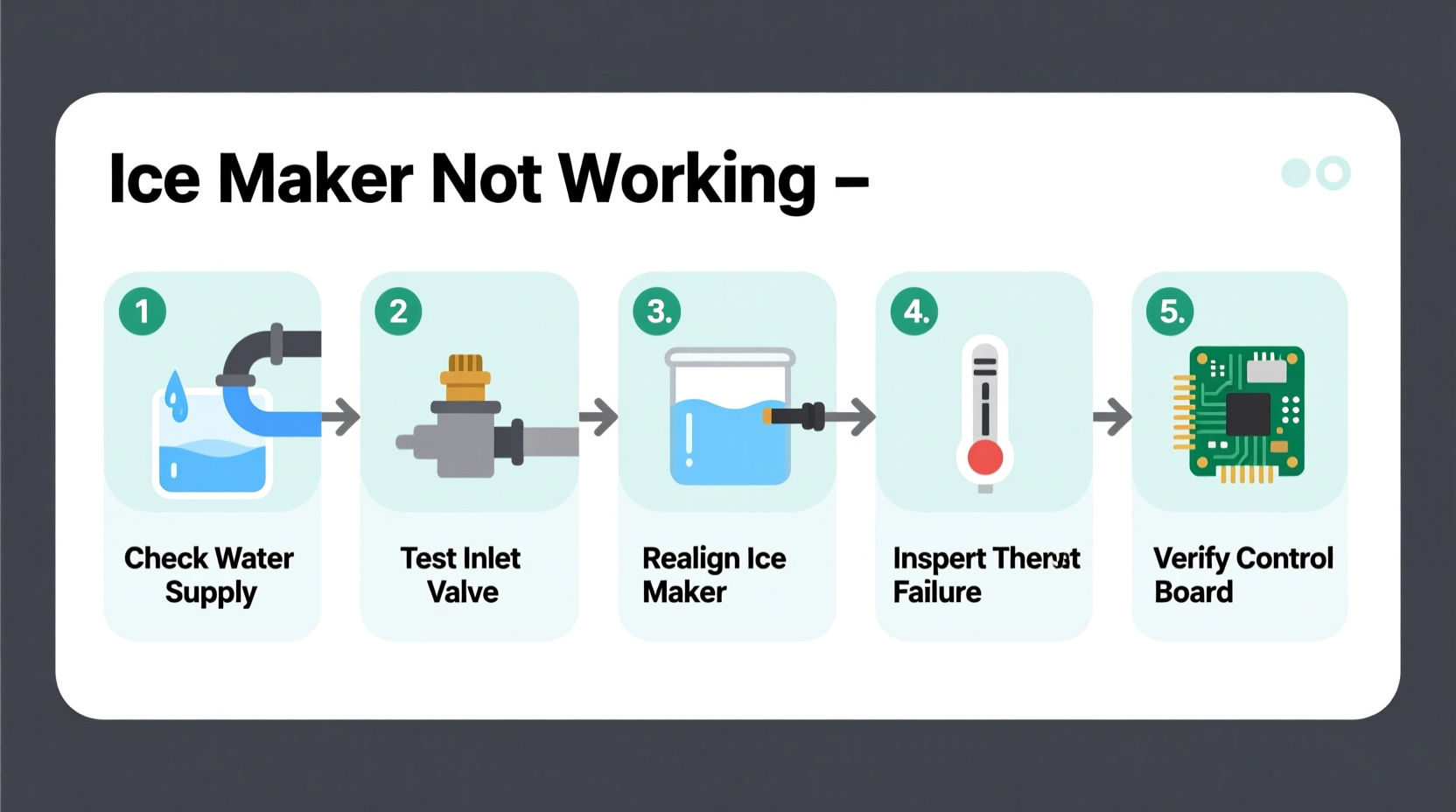

Step-by-Step Troubleshooting Guide

Follow this logical sequence to identify and resolve the most frequent causes of ice maker failure:

- Check the Ice Maker Switch – Ensure the on/off toggle is set to “on.” Some models have a small red LED indicator when active. If no light appears, there may be an electrical fault.

- Inspect the Freezer Temperature – The unit must operate below 17°F (-8°C) for proper cycling. Use a standalone thermometer to verify readings, especially if the main display seems inaccurate.

- Verify Water Supply Line Integrity – Locate the water line connected to the back of the fridge. Look for kinks, bends, or shutoff valve closures. A partially blocked line reduces pressure and halts ice production.

- Examine the Inlet Valve – This valve controls water flow into the ice mold. If clogged or failed electrically, no water enters. Listen for a faint click when the cycle should start; silence suggests valve failure.

- Flush the Water Line – Disconnect the line and run water through it into a bucket. Sediment buildup or frozen sections block flow, especially in older homes with hard water.

- Test the Ejector Gear and Motor – Remove the ice maker module and look for worn teeth or jammed mechanisms. Manual resistance indicates motor strain or gear damage.

- Reset the Unit – Unplug the refrigerator for 10 minutes to reset electronic controls. Plug back in and initiate a test cycle.

This process eliminates over 80% of common issues without requiring professional help.

Top 5 Causes and Their Solutions

| Cause | Symptoms | Solution |

|---|---|---|

| Low freezer temperature | No ice, delayed cycles | Adjust thermostat; ensure door seals tightly |

| Clogged water filter | Slow filling, thin cubes | Replace filter every 6 months |

| Kinked or frozen water line | No water delivery | Thaw line with hair dryer or replace tubing |

| Failed inlet valve | No sound at fill stage | Test coil resistance; replace if open circuit |

| Jammed ejector mechanism | Ice forms but doesn’t release | Clean mold; check for broken gears |

Mini Case Study: Resolving a Frozen Water Tube

Mark from Minneapolis noticed his Samsung refrigerator stopped making ice after a particularly cold winter week. He confirmed the switch was on and the freezer was at 10°F, yet no water entered the tray. After checking the shutoff valve and finding it open, he disconnected the water line behind the fridge. Only a trickle came out. Suspecting a freeze blockage inside the door, he used a hairdryer to warm the dispenser area for 15 minutes. Upon retesting, water flowed freely, and within two hours, new ice began forming. The culprit? A section of plastic tubing running through the freezer door had frozen due to poor insulation and low ambient humidity accelerating heat loss.

“Many so-called ‘broken’ ice makers are simply starved of water or trapped in temperatures too high to cycle. Ninety percent of calls we get end up being user-fixable.” — Carlos Mendez, Appliance Repair Technician with 14 years of field experience

Essential Maintenance Checklist

Prevent future breakdowns by following this routine maintenance checklist:

- ✅ Replace water filter every 6 months (or per manufacturer schedule)

- ✅ Clean ice bin and mold with mild vinegar solution quarterly

- ✅ Inspect water line for kinks annually

- ✅ Verify freezer temperature monthly using an independent thermometer

- ✅ Clear any frost buildup around the ice maker assembly

- ✅ Run a diagnostic cycle (if available via model-specific button combo)

Frequently Asked Questions

Why does my ice maker make noise but produce no ice?

The motor may be running, but if no water fills the mold, the issue lies upstream—typically a failed water inlet valve, clogged filter, or closed supply valve. Check each component systematically.

Can I bypass the water filter to test the ice maker?

Some refrigerators allow temporary bypass mode, but many will disable the ice maker entirely without a filter installed. Consult your manual. Never operate long-term without filtration—sediment harms internal parts.

How long should an ice maker cycle take?

A full cycle—from fill to ejection—typically takes 90 to 120 minutes under optimal conditions (freezer at 0°F or lower). Colder temps speed up freezing; warmer temps delay or stall the process.

When to Call a Professional

While many issues are DIY-friendly, certain situations require expert intervention:

- No power reaching the ice maker module (confirmed with multimeter)

- Visible leaks from internal plumbing or cracked valve housing

- Repeated failure after part replacement

- Error codes displayed on digital panels (e.g., “5E,” “IC”)

In these cases, wiring faults, control board malfunctions, or refrigerant issues may be involved. Attempting advanced repairs without training risks personal injury or voiding warranties.

Conclusion

An ice maker not working doesn’t automatically mean replacement is necessary. By methodically evaluating temperature, water flow, mechanical movement, and electrical signals, most homeowners can restore function quickly and affordably. Regular maintenance prevents recurring issues and extends appliance lifespan. Modern refrigerators integrate complex systems, but their core principles remain accessible with basic tools and informed effort.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?